Time: Popularity:0times

Capillary rheometers are the most mature rheological instruments currently available. They are primarily used to measure the viscosity of materials and are particularly well-suited for measuring shear viscosity, which is related to shear rate and pressure. They are widely used. Fluid viscosity is defined as the ratio of the shear stress to the shear rate experienced by a unit of fluid.

Thus, by accurately measuring the shear stress and shear rate of a fluid, the viscosity of the fluid can be determined. In addition to measuring fluid viscosity, capillary rheometers can also characterize the elastic behavior of fluids through the study of extrusion rheology. Capillary rheometers are primarily categorized as constant-velocity and constant-pressure rheometers. The former maintains a constant plunger velocity and measures the pressure difference between the ends of the capillary tube to obtain rheological information. Most high-pressure capillary rheometers are of the constant-velocity type.

Constant-pressure capillary rheometers use the opposite measurement principle to constant-velocity capillary rheometers. Constant-pressure rheometers maintain a constant plunger pressure, and the measured value is the extrusion rate of the liquid. Typical applications include melt index measurement in the plastics industry. Another type of capillary rheometer is a gravity capillary rheometer, where the sample is injected into the barrel without applying variable pressure, but rather relies on gravity to flow through the capillary.

Rotational rheometers generate shear stress through rotational motion, which facilitates rapid assessment and analysis of the viscoelastic properties of the material being measured. Depending on the structure of the measuring rotor, rotational rheometers are further categorized as cone-plate rheometers, parallel-plate rheometers, and coaxial cylinder rheometers. All three types of rheometers are based on the deformation evolution of the Newtonian parallel-plate model. Rotational rheometers are best suited for very low shear rate measurements, enabling the measurement of material structural changes using low-amplitude oscillations. They can also be used for pressure oscillation measurements and for testing and analysis related to yield stress, creep, and creep recovery.

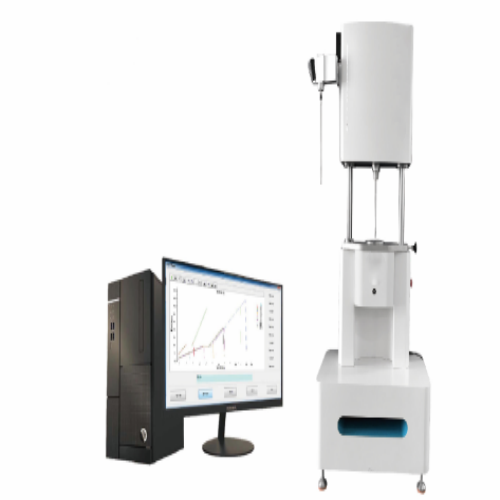

The QINSUN Capillary Rheometer complies with multiple standards, including DIN 54811. ASTM D 3835. and ISO 11443. It features a single-column oscillating head design, ensuring structural strength and easy cleaning. The drive mechanism utilizes a Taiwanese precision ball screw for kinetic energy transfer, and the speed control system utilizes an AC servo system for precise displacement and pressure control. The heating mechanism utilizes a spiral heating wire for integrated heating, ensuring uniform barrel temperature. The high-tech measurement and control system and intuitive software interface allow for setting test modes and related operating parameters, and displays relevant curves and calculation results in real time.

A capillary rheometer consists of a single-screw extruder, a capillary die, and an automatic weighing unit.

A torque rheometer consists of a frame assembly, drive assembly, torque sensor, transmission assembly, mixing chamber assembly, feeding assembly, safety devices, measurement and control system, control system, melt measurement system, electrical cabinet, and electrical safety.

A capillary rheometer is a device used to measure shear stress rate under high stress. It is used to measure the relationship between shear stress and shear rate of polymer melts in a capillary tube, directly observe the shape of the extrudate, study the elasticity and instability of the melt by changing the aspect ratio, and measure polymer state changes.

In a torque rheometer, the material to be tested is added to the mixing chamber. The material is continuously mixed and sheared between the rotors and the chamber wall due to the force exerted by two rotors rotating at different speeds and in opposite directions. The rotor ridges are also subjected to a reaction force from the material. The torque rheometer measures this reaction force using the torque sensor and processes it using computer software to generate a rheological spectrum showing the torque changing over time.

Capillary rheometers are used to measure the relationship between shear stress and shear rate in polymer melts in capillaries, directly observe the shape of the extrudate, study the elasticity and instability of the melt by varying the aspect ratio, and determine changes in polymer state. They can also perform apparent/true viscosity curve testing and measure and analyze die swell behavior.

Torque rheometers continuously, accurately, and reliably measure the rheological properties of materials by recording the reaction torque exerted on the rotor during mixing and the temperature changes over time. Applications include multi-component mixing, cross-linking and curing of thermosetting resins, vulcanization of elastomers, dynamic material stability, and the effect of screw speed on system processing performance.

Capillary rheometers operate at high shear rates, and are ideal for injection molding machines. They can be used to analyze changes in physical properties due to injection speed, and to optimize holding time and temperature.

Rotational rheometers operate at lower shear rates and are applicable to a wider range of production scenarios. For example, research on vitreous structures and interfacial rheological properties of polymer materials is also used in the production, processing, and manufacturing of textiles, food, pharmaceuticals, adhesives, cosmetics, bearing lubrication, grease, paint, slurry, and other industries.

| Comparison Dimensions | Capillary Rheometer | Rotational Rheometer |

|---|---|---|

| Core Principle | Polymer melts or solutions are extruded through a capillary tube under high pressure. The relationship between pressure and flow velocity is measured during flow, allowing calculation of shear stress, shear rate, and viscosity. | A rotating fixture (such as a cone-plate or parallel plate) applies steady-state or dynamic loads to the sample, measuring the stress-strain response and obtaining parameters such as viscosity and modulus. |

| Test Range - Shear Rate | 10² to 10⁵ s⁻¹, suitable for high-shear applications (such as injection molding and extrusion) | 10⁻⁶ to 10³ s⁻¹, covering low to moderate shear rates. |

| Test Range - Viscosity | 10² to 10⁸ Pa·s, suitable for high-viscosity materials (such as engineering plastics and rubber). | 10⁻³ to 10⁶ Pa·s, suitable for low-viscosity fluids (such as coatings and adhesives) and soft solids (such as gels and biomaterials). |

| Expanded Functionality | Analyze elastic behaviors such as die swell and melt fracture to guide process optimization. | Supports dynamic oscillation testing (frequency sweep and temperature sweep) to analyze material viscoelastic properties (storage modulus G′ and loss modulus G″). |

| Core Application Scenarios | Plastics Processing: Optimize injection temperature, hold time, and extrusion screw design. Rubber Vulcanization: Evaluate viscosity changes during vulcanization to guide process parameter adjustments. Composites: Study the flow behavior of fiber-reinforced materials to avoid processing defects. | Coatings R&D: Analyze thixotropy and yield stress to optimize application performance. Food Industry: Evaluate the rheological properties of creams and sauces to control mouthfeel and stability. Biomaterials: Study the viscoelastic properties of hydrogels and protein solutions to guide drug delivery design. |

| Advantages | Data directly correlates to actual production conditions, providing strong guidance. | Versatile functionality allows simulation of complex stress states (such as tension and compression). |

Capillary rheometers and rotational rheometers form a complementary yet distinct technical framework for rheological analysis of materials.

Capillary rheometers have distinct advantages in high-shear applications, and their measurement data can directly provide precise guidance for optimizing polymer processing. Rotational rheometers, on the other hand, are irreplaceable for studying materials' microstructures and low-frequency and dynamic mechanical properties, enjoying a wide range of applications.

In both scientific research and industrial practice, the choice of instrument depends on the specific testing objectives. If the focus is on simulating actual high-speed machining processes, a capillary rheometer is preferred; if the goal is to deeply analyze the viscoelastic and stability properties of the material itself, a rotational rheometer is a more ideal tool. Proper use of these two instruments will provide solid data support for new material development and product quality control.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com