Time: Popularity:0times

The amount of shrinkage depends on the fabric's fiber content, weave, finish, and the conditions it is exposed to. The process of measuring dimensional changes in fabric is called fabric shrinkage testing. This testing also includes changes in fabric quality.

Fabric shrinkage refers to the reduction in size or dimensions of a fabric or garment after exposure to heat or washing. Shrinkage can occur in both the longitudinal (warp) and transverse (weft) directions.

Fabric shrinkage can occur for a variety of reasons. Understanding these factors is crucial to minimizing shrinkage and maintaining fabric quality. The following are some common causes of fabric shrinkage:

Fiber Type

Different fiber types have different shrinkage tendencies. Natural fibers like cotton and wool shrink more than synthetic fibers like polyester or nylon.

Fabric Construction

The construction of a fabric, including its weave or knit structure, can affect shrinkage. Fabrics with looser weaves or knits are more likely to shrink than tightly woven or knitted fabrics.

Finishing Processes

The chemical treatments and finishes applied to fabrics during manufacturing can affect shrinkage. Certain finishes, such as pre-shrunk treatments, are designed to minimize further shrinkage after washing. However, if these finishes are not applied or the fabric is improperly treated, it may be more susceptible to shrinkage.

Heat and Moisture

Exposure to heat and moisture can trigger fabric shrinkage. Washing fabrics in hot water or drying them at high temperatures can cause fibers to shrink and lead to shrinkage. Similarly, excessive moisture or humidity can cause shrinkage, especially with natural fibers.

Mechanical Agitation

Vigorous mechanical action during the washing or drying process (such as high-speed spinning or tumble drying) can cause fabric shrinkage. Repeated friction and movement of fabrics can cause dimensional changes.

Improper Care

Failure to follow proper care instructions increases the risk of fabric shrinkage. Ignoring recommended washing temperatures, using harsh detergents, or harshly handling delicate fabrics can all lead to shrinkage.

Fabric Blends

Fabrics made from blends of different fibers may shrink unevenly. If the fibers in the blend have different shrinkage properties, the fabric may lose its shape or shrink unevenly during washing.

Different fabrics have different shrinkage rates due to their unique fiber composition. Here are some general guidelines for shrinkage rates for common fabric types:

Cotton

Cotton fabrics are known for their tendency to shrink easily. On average, cotton shrinks 3% to 5% in the first wash and subsequent washes. However, some cotton fabrics, such as those labeled "preshrunk" or preshrunk during the manufacturing process, may shrink less.

Wool

Wool is another natural fiber prone to shrinkage. It can shrink significantly, from 10% to 20%, especially if exposed to high temperatures or agitation during washing. To prevent excessive shrinkage, wool garments should be handled with care and washed using gentle methods.

Linen

Linen fabrics, derived from flax fibers, have a moderate shrinkage rate. On average, linen items shrink about 2% to 5% in the first wash. Subsequent washes may cause minimal additional shrinkage.

Silk

Silk fabrics generally have low shrinkage rates compared to other natural fibers. They tend to shrink around 1% to 3% during washing. However, some silk blends or special silk weaves may exhibit slightly higher shrinkage.

Polyester Fiber

Polyester is a synthetic fiber known for its shrinkage resistance. Its shrinkage is minimal, typically less than 1%. This quality makes polyester fabrics popular for items that need to retain their shape, such as sportswear and outdoor clothing.

Nylon

Nylon is another synthetic fiber with excellent dimensional stability. Like polyester, nylon fabrics exhibit minimal shrinkage, typically less than 1%. They retain their shape well even after repeated washing.

Blended Fabrics

Fabrics made from a blend of different fibers will exhibit different shrinkage rates depending on their composition. The shrinkage behavior of a blended fabric is influenced by the individual fibers it contains.

Fabric Shrinkage Tests are used to measure and evaluate the dimensional changes that occur in fabrics after washing, drying, or heat exposure. These tests help understand a fabric's potential shrinkage and make informed decisions about fabric selection, sizing, and care.

There are generally specific test standards and methods for fabric shrinkage testing:

Testing Standards

Fabric shrinkage testing is typically conducted according to recognized industry standards. Some commonly used standards for fabric shrinkage testing include:

ASTM D3774: Standard Test Method for Width of Textile Fabrics

ASTM D4970: Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics

ISO 6330: Textiles – Home Washing and Drying Procedures for Testing Textiles

AATCC TM135: Dimensional Change of Woven and Knitted Fabrics After Automatic Home Laundry

Test Methods

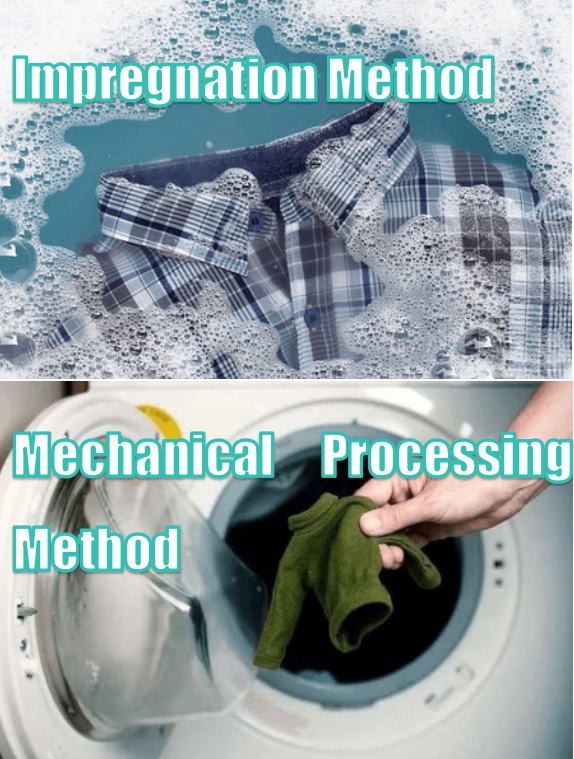

Two common test methods for fabric shrinkage testing are the immersion method and the mechanical treatment method. These methods are used to evaluate the dimensional change and shrinkage of fabrics. Let's explore each method in detail:

Immersion Method

The immersion method involves immersing a fabric sample in a liquid solution before testing. The immersion solution typically consists of water and any additional chemicals or detergents specified by the test standard or procedure.

Mechanical Treatment Method

The mechanical treatment method involves subjecting a fabric sample to mechanical stress or agitation to evaluate its shrinkage behavior. This method is designed to replicate the effects of mechanical action during washing or drying.

Mechanical treatment methods allow for the evaluation of fabric shrinkage caused by mechanical forces, providing insight into a fabric's response to agitation and friction.

The Fabric Washing Shrinkage Tester is a specialized instrument for testing the dimensional change of textiles after washing. It complies with over ten international standards, including AATCC 88B, 88C, 124. 130. and 135. This instrument combines washing and drying functions, primarily used to determine the shrinkage or elongation of textiles after one or more washes, providing accurate data for the development of clothing and textile care labels.

Intelligent Control System: The washing unit utilizes an agitator and water temperature control system to ensure washing results and temperature accuracy. The drying unit is equipped with a sensor drying system, silent drying, and anti-wrinkle cold air functions, enabling precise control of drying time and providing a low-noise operating environment.

User-Friendly User Interface: The touchscreen interface allows for selection of various parameters, including wash program, temperature, water level, temperature level, and water flow stages.

A wide selection of wash programs: 10 wash programs are available (Normal, Normal, Heavy, Gentle, Soak, and Super Wash), with three additional options including an extra rinse function.

Multiple adjustable parameters: Four load sizes/water levels and four temperature settings are available to meet diverse testing needs.

High-quality construction: A ceramic top cover and dual smooth ceramic drums ensure wear resistance; the dual suspension system provides self-balancing and stability.

The instrument also offers optional accessories such as AATCC standard fluorescent detergent, matching wash cloths, a washfast pen, a ruler with a dial, and a standard printed ruler, providing a complete solution for textile washability testing.

Calculating fabric shrinkage involves using a scale to measure the dimensional change of the fabric before and after the test. The shrinkage percentage is determined by comparing the initial and final dimensions of the fabric. Here's how to calculate shrinkage:

Initial Measurement: Measure the dimensions of the fabric sample before any testing or treatment using a shrinkage template scale. This includes measuring the length, width, and any other relevant dimensions. Record these initial measurements.

Testing Procedure: Follow the specific testing procedure according to the selected method. Ensure that the fabric sample meets the required conditions, such as immersion in the impregnation solution or mechanical agitation. Follow the test procedure accurately.

Final Measurement: After the testing process is complete, carefully remove the fabric sample from the testing equipment. Allow it to dry or perform any necessary post-processing according to the test standard or procedure. After drying, measure the dimensions of the fabric sample again using a shrinkage template scale.

Calculation Formula: Using the initial and final measurements at hand, calculate the fabric shrinkage using the following formula:

Shrinkage Percentage = [(Initial Dimension - Final Dimension) / Initial Dimension] x 100

For example, if the initial length of the fabric sample is 100 cm and the final length after testing is 90 cm, the calculation is:

Shrinkage Percentage = [(100 – 90) / 100] x 100 = 10%

The resulting value represents the percentage of shrinkage that occurred during the test.

If you want an instrument that can automatically calculate fabric shrinkage, our latest shrinkage tester is a good choice.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com