Compared to standard EN 60312. the TVE 3000 offers a more cost-effective and efficient way to test v

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

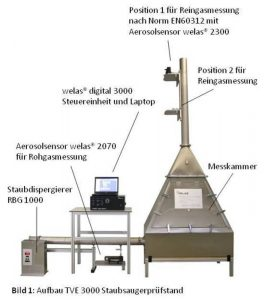

Compared to standard EN 60312. the TVE 3000 offers a more cost-effective and efficient way to test vacuum cleaners. Furthermore, dust (or, as an option, salt – such as NaCl or KCl in the AGK 2000 salt generator) can be used to reliably distinguish the separation behavior of bagged vacuum cleaners from HEPA terminal filters. The dust disperser RBG 1000 used is far more uniform than required by the standard, thus providing optimized dust application, a prerequisite for accurately measuring separation efficiency using particle measurement equipment.

Using the 2000 particle measurement system in the purified gas, and with the aid of the 2300 aerosol sensor, the emissions of vacuum cleaners can be measured according to standards. Therefore, not only can vacuum cleaners be accurately compared, but individual filtration stages can also be reliably evaluated.

Using the 3000 particle measurement system, users have access to a high-resolution aerosol spectrometer, allowing for near-simultaneous determination of particle size distribution and particle concentration in both the feed gas and the purified gas.

The 2070 aerosol sensor accurately determines the measurement of feed gases, while the 2300 aerosol sensor can be used in purified air and allows for the measurement of the grading efficiency of vacuum cleaner bags and HEPA terminal filters.

EN 60312

| Measuring range (dimensions) | 0.2 µm – 40 µm |

| Measuring range (quantity in CN) | < 1 – 1.000.000 particles/cm³ |

| Power supply | 115/230 V, 50/60 Hz |

| External dimensions | 2.100•2.600•600 mm (H•W•D) |

| Weight | Approximately 170 kg |

| Compressed air connection | 6 – 8 bar |

| Volume flow rate (inhalation flow rate) | The system's volumetric flow rate depends on the vacuum cleaner. |

Dust is introduced into the system using the RBG 1000 dust disperser. The reproducibility of dust concentration is <10%.

The 2070 aerosol sensor measures the particle size distribution and particle concentration of the feed gas (above the vacuum cleaner). The vacuum cleaner draws in dust, which is then separated in the vacuum bag and the HEPA terminal filter. The 2300 aerosol sensor then measures the vacuum cleaner emissions on the purified gas side (above the vacuum cleaner). Based on the measurements of the feed gas and purified gas, the vacuum cleaner's staged separation efficiency can be determined.

FTControl software allows for multiple staged separation efficiency measurements of different vacuum cleaners, displayed simultaneously on the screen.

Both the dust disperser and purified gas sensor can be positioned at different locations to study the effect of flow channels on particle settling.

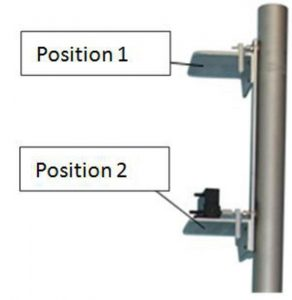

Location of the Purified Gas Sensor: The aerosol sensor for measuring purified gases can be positioned in two different locations.

Location 1 is the purified gas measurement point according to standard EN 60312.

The purified gas sensor can operate in either location 1 or location 2. for example, to investigate sedimentation and other transmission losses in the suction channel. Location 1 conforms to the following standards.

Figure 2: Purified Gas Sampling

Location of Dust Disperser RBG 1000:

The figure shows the connection of RBG 1000 according to standard EN 60312. or its positioning at the inlet of the front flow channel to ensure no deposits in the aerosol inlet elbow.

Measuring Stage Separation Efficiency

Based on the measurements of the feed gas and the purified gas, the stage separation efficiency of the vacuum cleaner or vacuum cleaner filter stage can be determined.

Figure 3: Measuring the staged separation efficiency of a complete vacuum cleaner system, including vacuum bags and HEPA terminal filters.

Simultaneous measurement of particles in feed and clean gases

• Highest metrological consistency with dust dispersers RBG 1000 or AGK 2000

• Measurement of particle size distribution and concentration in feed and clean gases

• Emission measurement according to standard EN 60312

• Measurement of staged separation efficiency of dust bags

• Measurement of staged separation efficiency of HEPA terminal filters

• Measurement of staged separation efficiency of complete vacuum cleaner systems

• Low maintenance

• Easy to operate

• Reliable operation

• The equipment will reduce your operating costs

Emission measurement according to standard EN 60312

• Measurement of staged separation efficiency of bagged vacuum cleaners and vacuum cleaners with HEPA terminal filters

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com