Time: Popularity:0times

With the continuous expansion of the global road network and the continued growth in vehicle ownership, the environmental challenges faced by vehicles during daily driving are becoming increasingly severe. Especially on highways, in gravel-prone areas, or around construction sites, the impact of road debris, ice, and other hard objects on vehicle components has become a key factor affecting vehicle durability, safety, and appearance. Gravel impact can not only damage the paint and crack glass, but also damage critical functional components such as sensors, cooling systems, and lighting, thereby affecting vehicle performance and passenger safety.

Against this backdrop, gravel impact testing has become a crucial step in automotive R&D and quality assurance. This test simulates the high-speed impact of particles on vehicle components in real-world road conditions to assess whether their impact resistance, structural integrity, and functionality meet design requirements. Currently, major domestic and international automakers and parts suppliers have incorporated gravel impact testing into their mandatory testing specifications, covering a wide range of components, from exterior components to safety structures.

This article will focus on the specific applications of the gravel impact test in the automotive industry, highlighting its practical significance in the manufacturing of smart electric vehicles and high-end components.

The gravel impact test, also known as the Gravelometer test, is an accelerated testing method that simulates real-world road damage by firing particles of a specific type, size, and velocity at automotive parts. This test is primarily used to evaluate coating adhesion, material brittleness resistance, sealing performance, and structural durability. Currently, multiple standards have been established internationally, including international standards (such as ISO), regional standards (such as SAE and DIN), and company standards (such as the technical specifications of major OEMs).

These standards typically specify the impact medium (e.g., steel balls, natural gravel), injection pressure, impact angle, temperature conditions, and evaluation methods. For example, SAE J400 and DIN 55996-1 primarily address coating systems, while QC/T 468 and GB/T 32060 apply to radiators and glass components, respectively. With the development of smart electric vehicles, testing standards for emerging components (such as cameras, radomes, and battery underbody shields) are continuously expanding and improving.

Exterior body panels are most frequently subjected to gravel impact, particularly the front bumper, hood, lower door panels, and side skirts. Impact not only damages the paint finish but can also penetrate the coating, causing corrosion to the metal substrate, seriously impacting the vehicle's lifespan. Therefore, OEMs generally require coating systems to undergo multiple impact tests at multiple angles and are graded based on the damage area and depth.

Currently, domestic companies such as Great Wall and Geely have established strict corporate standards. For example, Great Wall Motors' Technical Specification Q/CC JT122-2009 explicitly requires that PVC primer protective adhesives must pass gravel impact testing under specific conditions. High-end brands tend to combine cyclic corrosion testing (CCT) for comprehensive evaluations to simulate the complex environmental loads experienced in actual use.

The windshield and headlamp housing are the most vulnerable transparent components on the front of a vehicle, and their resistance to gravel impact is directly related to driving safety. Cracks in the glass or damage to the headlamp housing can affect optical performance and sealing, increasing driving risks.

Although originally developed for high-speed trains, China's national standard GB/T 32060-2015 has been cited or referenced by many automotive companies to standardize windshield impact test methods. Regarding lighting systems, in addition to the impact resistance of the lens itself, manufacturers must also consider whether structural deformation of the housing could cause dimming failure.

With the rapid development of autonomous driving technology, sensors such as cameras, LiDAR, and millimeter-wave radar are being installed in large numbers on vehicles. These precision devices are often located around the vehicle (such as the front and rear bumpers, exterior mirrors, and roof), making them highly susceptible to gravel impact.

For example, a cracked lens or housing displacement in a camera can cause calibration parameter drift, blurred images, or even loss of functionality. The industry standard QC/T 1128-2019 specifies mechanical environmental testing items for camera assemblies, specifically including gravel impact testing. New energy vehicle manufacturers such as Tesla, Xpeng, and NIO have further enhanced these testing requirements to accommodate more complex operating scenarios.

Heat exchange components such as radiators, intercoolers, and condensers are often located at the front of the vehicle, facing the wind and exposed to gravel impact. Penetration or deformation of the heat sink can reduce heat dissipation efficiency and even cause coolant leaks.

QC/T 468-2010. "Automotive Radiators," specifies impact testing using steel balls with a hardness of 61-65 HRC to simulate extreme operating conditions. In electric vehicles, battery coolers are more tightly integrated with front-end modules, placing even greater demands on impact resistance.

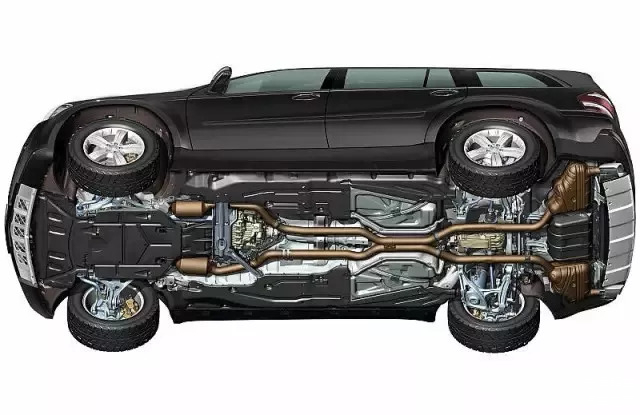

In gasoline-powered vehicles, chassis components (such as fuel lines, brake fluid lines, and springs) must be protected against mechanical damage or accelerated corrosion caused by gravel impact. In electric vehicles, the power battery pack located under the vehicle's underbody becomes a key protection target. The battery housing (especially the underbody guard) must possess extremely high impact resistance to prevent gravel impacts that could cause short circuits, thermal runaway, and other serious safety incidents.

Currently, electric platforms such as the Volkswagen MEB and Geely SEA require battery packs to meet IP67 protection levels or higher and undergo multiple mechanical tests, including gravel impact testing. Typical testing methods include impacting a designated location at a 90° angle and inspecting for structural cracks or seal failure.

Exposed components such as the grille, wheels, fenders, and parking radar domes also require impact resistance verification. For example, damage to the wheel surface coating can accelerate corrosion of the aluminum alloy, while damage to the radome can affect signal transmission and reception accuracy.

Against the backdrop of the automotive industry's transition toward electrification and intelligent driving, the application of gravel impact testing has taken on new industry characteristics and technical priorities.

Smart electric vehicles generally feature more exposed sensors, lower chassis (to accommodate batteries), and more complex aerodynamic designs, all of which increase the risk of stone chip impact. Consequently, emerging automakers are generally strengthening testing conditions beyond traditional standards:

Sensor Protection: For lidar and cameras, functional impacts must be assessed in addition to mechanical impact. For example, calibration parameter offsets and image distortion must be detected after impact.

Battery Pack Safety Testing: Battery underbody guards are often made of composite materials or metal alloys. Post-impact deformation measurements and seal integrity checks are required during testing.

Aerodynamic Components: Active grille vanes and side skirt deflectors must be verified for continued function after impact testing.

Lightweight materials such as carbon fiber, as well as premium paint finishes (such as matte and pearlescent finishes), are widely used in luxury and performance vehicles and are more sensitive to stone chip impact. To address this, companies often develop customized testing methods. For example:

Brands such as Porsche and Ferrari have established stricter impact energy and evaluation standards for carbon fiber front lips and diffusers.

The application of new materials such as ceramic coatings and self-healing clearcoats has also driven the development of testing methods towards multi-dimensional damage analysis.

The standardization and effectiveness of gravel impact testing requires collaboration across the entire automotive supply chain. Raw material suppliers (such as BASF and PPG), component manufacturers (such as Valeo and Hella), and OEMs (such as Toyota and Volkswagen) must jointly develop technical specifications to ensure that test conditions are well aligned with actual road conditions.

Furthermore, as Chinese auto brands expand globally, compliance with international standards such as ISO and SAE has become a fundamental requirement for entering overseas markets. Domestic testing organizations (such as the China Automotive Engineering Research Institute and the Shanghai Motor Vehicle Inspection and Certification Technology Research Center) have also established comprehensive gravel impact testing capabilities, supporting industry innovation and quality improvement.

Modern gravel impact testing machines have evolved from simple pneumatic jet devices to comprehensive testing platforms that can precisely control impact angle, velocity, temperature, and media type. Key technological advancements include:

Multi-degree-of-freedom specimen positioning system: capable of simulating component layouts for different vehicle models;

Environmental simulation chamber: enabling impact testing under high, low, and humid conditions;

Quantitative evaluation methods: such as 3D scanning analysis of impact crater volume and automated coating damage rating systems;

Application of digital twin technology: predicting impact damage through simulation, reducing the number of physical tests.

Gravel impact testing, as a key component in verifying the durability of automotive components, is expanding its application beyond traditional body panels to include emerging areas such as smart sensors and battery protection systems. With the deepening technological transformation of the automotive industry, the technical content and standardization system of this test are continuously enriched and improved.

In the future, with the widespread application of new materials (such as transparent polyurethane radomes and self-healing coatings) and new structures (such as battery-chassis integration), gravel impact testing will continue to develop towards higher accuracy, closer alignment with actual operating conditions, and more diverse evaluation indicators. Furthermore, through international harmonization of test standards and industry-wide sharing, the quality and durability of automotive products are expected to be further improved, ultimately providing safer and more reliable vehicles to consumers worldwide.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com