The air-cooled xenon lamp aging tester is a device that uses an air-cooled system to dissipate heat

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Recommended related products:

Xenon light fastness tester: Tabletop Lightfastness Tester (SunMaster)

Light Fastness Testing Tester: Lightfastness Tester Si3000 (Fade-Ometer)

xenon arc weatherometer: Xenon Arc Weather Ometer Si4000

Accelerated Weathering Tester: UV Accelerated Weathering Tester (UVtest)

What is A Light Fastness Tester?

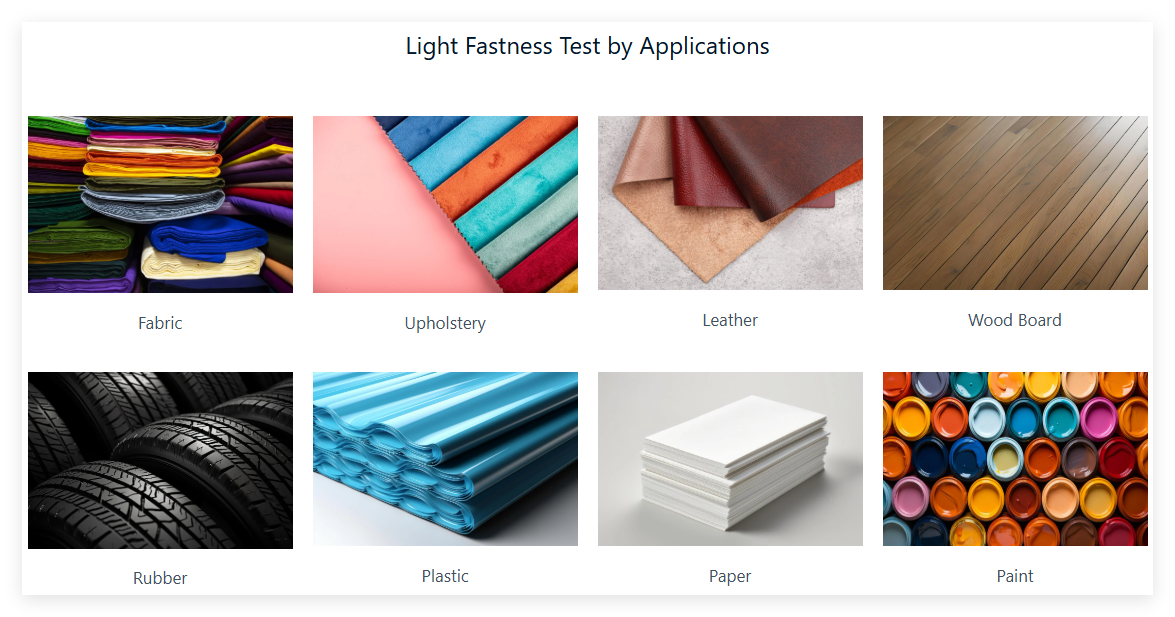

A Light Fastness Tester, or Xenon Tester, Accelerated Ageing Chamber, is used for xenon arc testing in dye fastness tests for lightfastness and weather resistance.Light fastness tester apply to light color fastness, anti-climate color fastness, light & perspiration color fastness and light aging tests of textile, paint, dye, coating, rubber, plastic, wood floor, paper and other materials, it have anti-climate functions of exposing to the rain, revolution and mist spraying.Light Fastness Tester are of two different cooling method: water cooling and wind cooling.

Application:

Qinsun si220 is a highly economic material color lightfastness tester that can test up to 250 samples simultaneously. It complies to industry standards ISO 105- B02, AATCC TM16 (option 3), and Marks & Spencer C9, C9A.

This light fastness tester is also apply to light color fastness, anti-climate color fastness, light & perspiration color fastness and light aging tests of paint, dye, coating, rubber, plastic, wood floor, paper and other materials, it have anti-climate functions of exposing to the rain, revolution and mist spraying.

Standard Compliance:

AATCC TM16-2004:Colorfastness to Light

AATCC TM16.3:Colorfastness to Light

AATCC TM169:Weather Resistance of Textiles: Xenon Lamp Exposure

ASTM G155:Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

ISO 4892-2:Plastics - Methods of exposure to laboratory light sources - Part 2: Xenon-arc sources

ISO 16474-2:Paints and varnishes - Methods of exposure to laboratory light sources - Part 2: Xenon-arc lamps

ISO 105-B02:Textiles - Tests for colour fastness - Part B02: Colour fastness to artificial light: Xenon arc fading lamp test

ISO 105-B04;Textiles - Tests for colour fastness - Part B04: Colour fastness to weathering: Xenon arc test

ISO 105-B10:Textiles - Tests for colour fastness - Part B10: Artificial weathering - Exposure to filtered xenon-arc radiation

M&S C9:Colorfastness to Light

M&S C9A:Colorfastness to wet light in the presence of alkaline or other chemical residues

For more relevant testing standards, please consult our professional engineers.

Energy-Efficient Air Cooling System

Eliminates the need for water chillers, reducing energy consumption by up to 40% compared to traditional water-cooled models.

Low-noise operation (<60 dB) ensures a quiet testing environment.

Cost-Effective Maintenance

No water pipes, filters, or coolant replacements required. Simplified design minimizes downtime and maintenance costs.

Rapid Thermal Cycling

Achieve temperature shifts from -20°C to 80°C in <10 minutes, accelerating test cycles without compromising accuracy.

Advanced Spectral Control

Precision filters mimic natural sunlight (UV, visible, and IR spectra) for realistic aging simulation.

User-Centric Design

10.4” touchscreen with intuitive interface, multi-language support, and remote monitoring via Wi-Fi/Ethernet.

Dual-Mode Cooling Technology

Combines forced-air convection with a high-efficiency heat sink to stabilize lamp temperature during prolonged tests.

Intelligent Irradiance Control

Closed-loop feedback system maintains ±0.02 W/m² irradiance accuracy (300–400 nm range).

Programmable Climate Control

Independent settings for temperature (-20°C to 100°C), humidity (10%–95% RH), and rainfall simulation (0–50 cycles/hour).

Safety First

Overheat protection, emergency stop, and UV-shielding acrylic door ensure operator safety.

Modular Expandability

Add-on modules for ozone control, salt spray corrosion, and mechanical stress testing.

Standard Kit:

1 × Air-Cooled Xenon Lamp (6500h lifespan)

2 × Adjustable Sample Racks (Max. 10 kg load)

1 × Calibrated Radiometer

1 × USB Data Logger (16GB)

1 × UV-Resistant Acrylic Viewing Window

Optional Add-Ons:

Humidity Control Module (-20°C to 80°C, 10%–95% RH)

Remote Monitoring Software (IoT-enabled)

Multi-Language Interface Pack (10+ Languages)

Spare Lamp Kit (2x Xenon Lamps + Filters)

| Specification | Details |

|---|---|

| Xenon Lamp Power | 2.2 kW (Air-Cooled, 6500h lifespan) |

| Test Chamber Size | 700 × 500 × 500 mm (W×D×H) |

| Temperature Range | -20°C to 100°C (±2°C accuracy) |

| Humidity Range | 10%–95% RH (±3% accuracy) |

| Irradiance Range | 30–120 W/m² (300–400 nm, adjustable) |

| Test Cycles | 1–9999 hours (programmable intervals) |

| Power Supply | 220V/50Hz/60Hz, 20A (Single-phase) |

| Dimensions (W×D×H) | 1200 × 800 × 1800 mm |

| Weight | 350 kg (Net) |

Our Qinsun Si 220 weathering tester can completely replace the Atlas Xenotest 220/220+ xenon lamp weathering tester, with reliable product quality, stable performance and accurate test data;

Recommended similar Light Fastness Testers:

1、Lightfastness Tester(Fade-Ometer)Si3000

2、Tabletop light fastness Tester

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com