Tests protective clothing flame spread per ISO 15025. Simulates fire for performance.

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

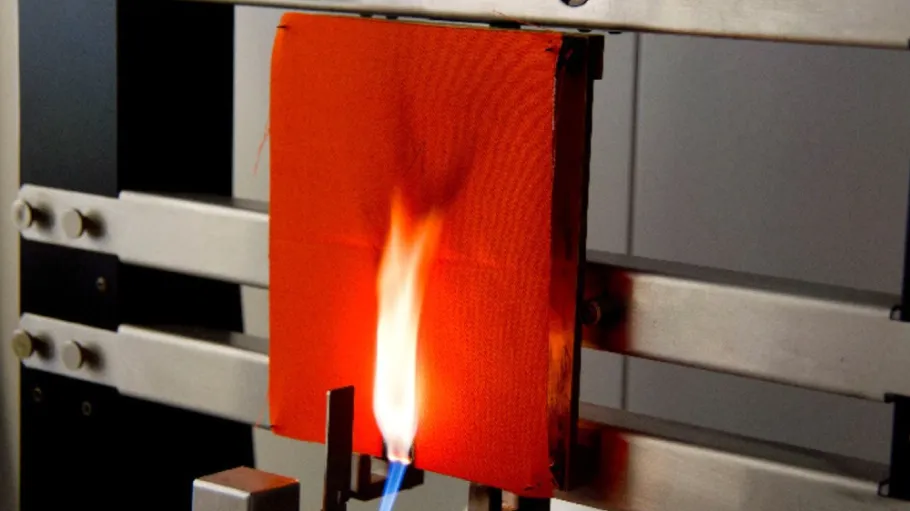

The Flame Spread Test Machine is designed for evaluating the flame spread performance of protective clothing and related materials under controlled small-flame exposure conditions. The instrument is developed and manufactured in accordance with ISO 15025, enabling accurate assessment of limited flame spread behavior when materials are subjected to ignition hazards.

It is used as a professional testing instrument for simulating flame diffusion performance of fire protective clothing, providing reliable data for product development, quality control, and regulatory compliance.

The Flame Spread Test Machine is applicable to flame spread and ignition hazard assessment across the following industries and products:

(1) Protective Clothing Industry: fire-fighting suits, heat-resistant garments, industrial protective clothing, multi-layer protective apparel

(2) Textile Industry: woven fabrics, knitted fabrics, coated textiles, quilted materials, laminated and sandwich structures

(3) Industrial Fabrics and Covers: curtains, large tents, awnings, door masks, industrial drapes

(4) Building and Interior Materials: decorative fabrics, wall coverings, interior textile panels

(5) Marine and Transportation Industry: marine interior materials, surface finishes, bulkhead and ceiling materials

(6) Aviation Industry: aircraft interior materials complying with Boeing and aviation flammability requirements

(7) Children’s and Safety Products: materials used in products requiring flammability control for safety purposes

(8) Research and Quality Inspection: laboratory testing samples, third-party certification testing, product performance verification

The instrument is suitable for new product development, production quality control, laboratory research, and third-party testing applications.

The instrument complies with and can be applied to the following international and domestic standards (including but not limited to):

(1) ISO 15025:2000 – Protective clothing — Protection against heat and flame — Method of test for limited flame spread

(2) BS EN ISO 15025:2002 – Protective clothing — Protection against heat and flame — Method of test for limited flame spread

(3) GB/T 5456-2009 – Textiles — Determination of flame spread properties of vertical specimens

(4) GB/T 6675.3-2014 – Safety of toys — Part 3: Flammability

(5) ISO 5658-2 – Reaction to fire tests — Spread of flame — Part 2: Lateral spread on building products in a vertical configuration

(6) IMO FTP Code Resolution A.653(16) – Fire test procedures for marine materials

(7) ASTM E1317 – Standard test method for flammability of marine surface finishes

(8) ASTM D3675 – Surface flammability of materials

(9) ASTM E1321 / ASTM E162 – Flame spread and heat release tests

(10) NF P 92-504 – Speed of flame spread test

(11) BS 476 Part 7 – Surface spread of flame test

(12) Boeing BSS 7304 – Aircraft interior material flammability

(13) UL 94 – Tests for flammability of plastic materials

(1) Transparent safety door with heat-resistant glass observation window for continuous monitoring during testing

(2) Fully enclosed test chamber minimizing external environmental interference

(3) Smart touch-screen control system with programmable microcomputer control

(4) Integrated test control, data acquisition, calculation, display, and report printing functions

(5) Adjustable burner angle with multiple mounting aids to meet different combustion angle requirements

(6) Automatic ignition system with precise timing control

(7) Automatic exhaust system ensuring safe removal of combustion gases

(8) Oversized test chamber adaptable to multiple standards by replacing specimen holders

| Item | Specification |

|---|---|

| Test Chamber | With observation window, internal black coating |

| Internal Volume | 0.5 m³ |

| Control Screen | Smart touch screen |

| Exhaust System | Automatic exhaust |

| Observation Window | Transparent heat-resistant glass |

| Distance from Burner Tip to Specimen | ≥ 75 mm |

| Flame Height | Adjustable |

| Burner Orientation | Horizontal or inclined |

| Sample Clamp Size | 190 mm × 150 mm (L × W) |

| Ignition Mode | Automatic ignition |

| Burning Timer | Digital timer, accuracy 0.1 s |

| Burner Combustion Tube | 8 tubes Ø 0.9 mm, 1 center tube Ø 1.7 mm |

| Overall Dimensions | 1400 mm × 900 mm × 1450 mm |

| Weight | 120 kg |

Test chamber with observation window

Burner assembly

Adjustable specimen holder

Automatic ignition system

Exhaust duct and fan system

Touch screen controller

Power cable

Operation manual

Calibration and inspection documents

(1) Prepare the specimen according to the applicable standard

(2) Install the specimen in the appropriate holder

(3) Adjust burner position, angle, and flame height

(4) Set test parameters via the touch screen

(5) Start automatic ignition and begin timing

(6) Observe flame spread behavior through the observation window

(7) Record flame spread time, damage length, and other required results

(1) Clean the test chamber and burner after each test to remove combustion residue

(2) Regularly inspect ignition and exhaust systems for proper operation

(3) Verify burner flame height and alignment periodically

(4) Check electrical and control components for stable performance

(5) Store and operate the instrument in a well-ventilated laboratory environment

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com