Electrical testing equipment G-ETE08, VEP-7600+VEP-7640D-4030-50k+VEP-7650(A&B) + software

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The VEP-7600 system is an advanced automotive electronic immunity testing platform designed based on ISO 7637-2/3 standards and mainstream automaker requirements. It provides full compliance with ISO 7637 standards and supports the simulation of thousands of transient disturbance waveforms through integrated hardware and software. LAS-7600 is targeted at automotive component manufacturers, supporting ISO 7637 Pulse 1, 2a, 2b, 3a, 3b tests and optionally Pulse 4, 5a, and 5b. The system includes CDN (Coupling/Decoupling Network) capacity up to 80V/100A.

(1) Automotive electronics industry testing for ECUs, sensors, and control modules.(2) Component suppliers performing ISO 7637-based transient immunity tests on 12V, 24V, and 48V vehicle systems.

(3) OEM and Tier 1 supplier quality control for automotive electrical systems.

(4) Research & Development of automotive electronics to validate transient immunity under standardized and custom automaker conditions.

(5) Compliance testing according to both international and domestic OEM standards.

(1) ISO 7637-2 – Road vehicles — Electrical disturbances from conduction and coupling — Part 2: Electrical transient conduction along supply lines only

(2) ISO 7637-3 – Road vehicles — Electrical disturbances from conduction and coupling — Part 3: Electrical transient transmission by capacitive and inductive coupling via lines other than supply lines

(3) GB/T 21437.2 – Automotive electrical transient immunity test standard (Part 2)

(4) GB/T 21437.3 – Automotive electrical transient immunity test standard (Part 3)

(5) GM 3097 – General Motors EMC testing guideline

(6) VW TL 81000 – Volkswagen transient immunity test specification

(7) SAIC SMTC 3 800 006 / SAIC Maxus CVTC 37003 – OEM-specific EMC test standards

(8) Changan VS-00.35-L-10008 – OEM transient immunity standard

(9) Xiaomi QMAT5501 – OEM EMC specification

(10) Geely Q-JLY7110779D – OEM EMC standard

(11) BYD QBYDQ-A1901.706.3 – OEM EMC guideline

(12) Ford FMC1278 / Dongfeng EQCS-1204 / GAC QJGAC 1523.029 – OEM EMC standards

(1) Built-in comprehensive automaker waveform library for direct testing of Pulse 1–3 and optional Pulse 4–5.

(2) Supports 12V, 24V, and 48V vehicle system testing.

(3) Master-slave architecture for unlimited system expansion.

(4) AUTOPRO software for remote control, waveform editing, test planning, automated reporting, and monitoring of EUT.

(5) Single-terminal output enables one-time setup to complete all tests.

(6) 7-inch capacitive touchscreen for user-friendly operation and high interference immunity.

(7) Integrated control for both hardware waveform output and software-based sequence management.

VEP-7610 Specifications

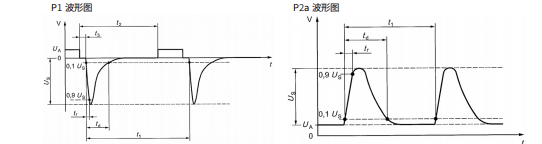

| Parameter | P1 Wave 12 V | P1 Wave 24 V | P2a Wave 12 V | P2a Wave 24 V |

|---|---|---|---|---|

| Output Voltage (Us) | 1 V ~ 300 V | 1 V ~ 700 V | 1 V ~ 150 V | 1 V ~ 300 V |

| Polarity | Negative | Positive | Negative | Positive |

| Output Resistance (Ri) | 2 Ω, 4 Ω, 10 Ω, 30 Ω, 50 Ω | 2 Ω, 4 Ω, 10 Ω, 30 Ω, 50 Ω | 2 Ω, 4 Ω, 10 Ω, 30 Ω, 50 Ω | 2 Ω, 4 Ω, 10 Ω, 30 Ω, 50 Ω |

| Pulse Width (Td) | 50 μs, 200 μs, 300 μs, 500 μs, 1000 μs, 2000 μs | 50 μs, 200 μs, 300 μs, 500 μs, 1000 μs, 2000 μs | 50 μs, 200 μs, 300 μs, 500 μs, 1000 μs, 2000 μs | 50 μs, 200 μs, 300 μs, 500 μs, 1000 μs, 2000 μs |

| Rise Time (Tr) | 0.5 μs ~ 1 μs | 1.5 μs ~ 3 μs | 0.5 μs ~ 1 μs | 0.5 μs ~ 1 μs |

| Test Count | 1 ~ 60,000 | 1 ~ 60,000 | 1 ~ 60,000 | 1 ~ 60,000 |

| Pulse Interval (T1) | 0.5 s ~ 60 s | 0.5 s ~ 60 s | 0.2 s ~ 60 s | 0.2 s ~ 60 s |

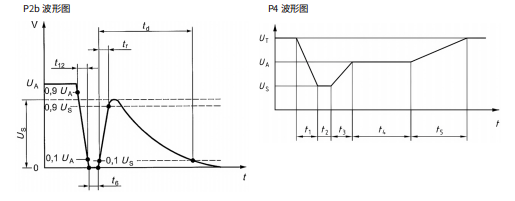

VEP-7620 Specifications

| Parameter | P2b Wave | P4 Wave |

|---|---|---|

| Output Voltage (Us) | 0 V ~ 80 V | 0 V ~ 50 V |

| Battery Voltage (UA) | N/A | 0 V ~ 50 V |

| Pulse Width (Td) | 0.1 s ~ 5.0 s | 1 ms ~ 999 ms |

| Rise Time (Tr) | 0.5 ms ~ 9.9 ms | 1 ms ~ 999 ms |

| Battery Fall Time (T12) | 0.5 ms ~ 9.9 ms | 1 ms ~ 999 ms |

| Waiting Time (T6) | 0.5 ms ~ 9.9 ms | 0.1 s ~ 99.9 s |

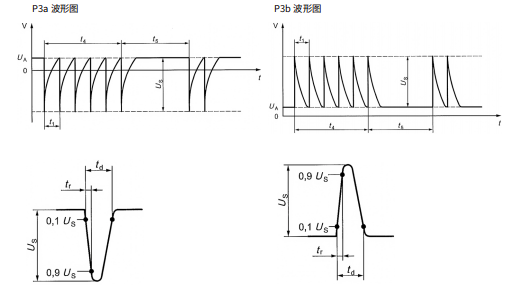

VEP-7630 Specifications

| Parameter | P3a Wave | P3b Wave |

|---|---|---|

| Output Voltage (Us) | 10 V ~ 600 V | 10 V ~ 600 V |

| Polarity | Negative | Positive |

| Rise Time (Tr) | 5 ns ± 30% (50 Ω load) / 5 ns ± 30% (1000 Ω load) | 5 ns ± 30% (50 Ω load) / 5 ns ± 30% (1000 Ω load) |

| Pulse Duration (Td) | 150 ns ± 45 ns (50 Ω / 1000 Ω load) | 150 ns ± 45 ns (50 Ω / 1000 Ω load) |

| Output Resistance (Ri) | 50 Ω | 50 Ω |

| Pulse Group Interval | 90 ms ~ 99,900 ms | 90 ms ~ 99,900 ms |

| Pulse Frequency | 0.5 kHz ~ 200 kHz | 0.5 kHz ~ 200 kHz |

| Pulse Group Width (T4) | 1 ms ~ 200 ms | 1 ms ~ 200 ms |

| Test Count | 1 ~ 60,000 | 1 ~ 60,000 |

| Coupling Mode | CCC / DCC | CCC / DCC |

| Output Interface | Source Port: BNC / Power Port: Coaxial Terminal | Source Port: BNC / Power Port: Coaxial Terminal |

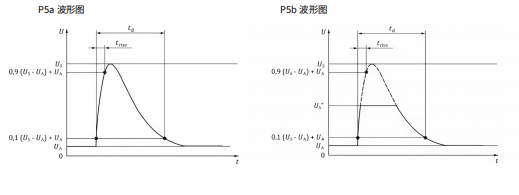

VEP-7650 Specifications

| Parameter | P5a Wave 12 V System | P5b Wave 24 V System |

|---|---|---|

| Output Voltage (Us) | 18 V ~ 100 V | 18 V ~ 210 V |

| Suppress Voltage (Us)* | 18 V ~ 100 V | 18 V ~ 199 V |

| Output Resistance (Ri) | 0.5 Ω ~ 8 Ω | 0.5 Ω ~ 8 Ω |

| Rise Time (Tr) | 5 ~ 10 ms | 5 ~ 10 ms |

| Pulse Width (Td) | 40 ms / 100 ms / 200 ms / 350 ms / 400 ms | 100 ms / 200 ms / 350 ms / 400 ms |

| Pulse Interval | 60 s ~ 999 s | 60 s ~ 999 s |

| Pulse Count | 1 ~ 60,000 | 1 ~ 60,000 |

| DUT Power Supply | Max 60 V | Max 30 A / 50 A / 100 A / 200 A |

| Serial Interface | LAN RJ45 | LAN RJ45 |

(1) Coupling/Decoupling Networks (CDNs)

(2) LAN Ethernet RJ45 interface

(3) AUTOPRO software package

(4) EUT connection cables and adapters

(5) User manual and calibration guide

(1) Connect the EUT to the system via the appropriate CDN.

(2) Select the desired waveform (Pulse 1–3 or optional 4–5) using AUTOPRO software.

(3) Set test voltage, polarity, pulse width, rise time, interval, and number of repetitions.

(4) Start the test sequence and monitor the waveform output via touchscreen interface.

(5) Record EUT response and system-generated report.

(6) Perform post-test verification and disconnect EUT safely.

(1) Regularly inspect CDNs, cables, and connectors for wear or damage.

(2) Calibrate waveform output and measurement channels annually.

(3) Update AUTOPRO software and waveform library as needed.

(4) Clean system and touchscreen interface regularly to prevent dust accumulation.

(5) Verify system grounding and electrical safety before each testing session.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com