Time: Popularity:0times

A cone calorimeter operates on the principle of oxygen consumption to determine a material's heat release rate (HRR). This principle states that the heat released per unit of oxygen consumed during combustion is approximately constant for most materials.

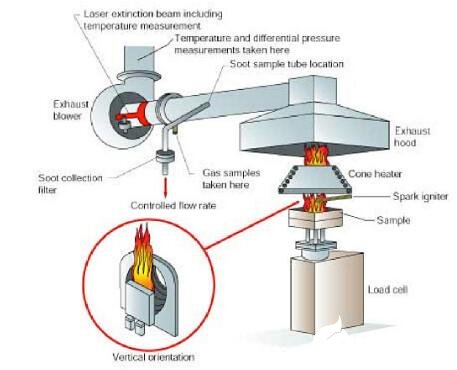

When a specimen is exposed to the radiant heat from a conical heater, the instrument measures key fire response parameters, including:

The generated heat is directly proportional to fire severity indicators, such as the fire growth rate. Assessing a material's flammability involves exposing it to a controlled external radiant heat source.

In a standard test, a sample is placed under the cone-shaped heater, typically exposed to a heat flux of 35 kW/m². For more fire-resistant materials, this flux is often increased to 50 kW/m². Ignition occurs once sufficient pyrolytic gases are produced. The resulting combustion gases are then captured through the heater and an instrumental exhaust duct for analysis.

Key measured and derived values include time to ignition, mass loss rate during combustion, peak heat release rate, and total heat released.

The cone calorimeter complies with major international test standards:

ISO 5660: Reaction to fire tests — Heat release, smoke production and mass loss rate

ASTM E1354: Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products

BS 476 Pt.15: Fire tests on building materials and structures — Method for measuring the rate of heat release of products

GB/T 16172-2007: Test method for heat release rate of building materials

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com