Time: Popularity:0times

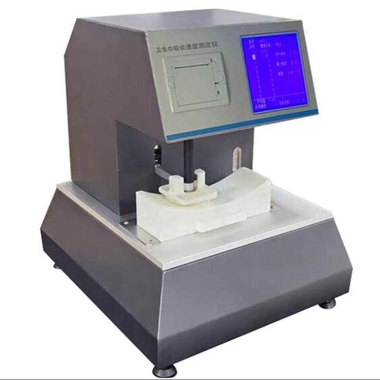

The Sanitary Napkin Absorption Speed Tester, designed and developed according to relevant standards, is used to measure the absorption rate of sanitary napkins, panty liners, and other products. Absorption rate, expressed in seconds, is the time it takes for a sanitary napkin sample to absorb a certain amount of test solution. This reflects the napkin's ability to absorb a rapidly approaching floodwater. Faster absorption rates prevent the surface of the sanitary napkin from becoming damp, reducing bacterial growth.

1. Plug in the national standard power cord to power the instrument, then flip the red rocker switch so the indicator light illuminates.

2. Click the [Set] button to enter the setup interface. Set the test solution volume, number of rinses, and the interval between rinses. Then, click [Next] on the setup interface to enter the next page of the setup interface to set the instrument speed, the number of penetrations required per test, and the interval between penetrations.

3. Click the [Test] button to jump to the test interface. Click the [Rinse] button to perform a vortex rinse on the test tube and wait for the rinse to complete. (You can set a larger test solution volume, such as 20 nL, initially. After rinsing, remember to adjust it back to the desired test volume.)

4. After rinsing, install the specimen and connect the upper fixture sensor to the instrument. Click the [Start] button and wait for the test to complete.

5. After the test is complete, click the [Report] button to enter the report interface to view the actual data.

6. After the experiment is complete, replace the test solution with cleaning solution. Open the settings interface and set the number of rinses to at least 5. with a rinse time equal to !, to rinse the test tubes multiple times to remove any residual test solution.

7. When not performing experiments, rinse the pipes with clean water.

1. Avoid impacting the instrument during transportation, installation, adjustment, and use to prevent mechanical damage that could affect test results.

2. The instrument must be placed in a work area away from vibration sources and free from visible air convection to avoid affecting test results.

3. The instrument should be inspected weekly during regular use to ensure proper operation. If the instrument is used occasionally, moved, or repaired, it should be inspected before any test.

4. The instrument should be calibrated regularly according to regulations, no more than every 12 months.

5. If any internal mechanical malfunction occurs in the instrument, please contact the manufacturer or have it repaired by a qualified technician. The instrument is calibrated before shipment. Non-professional technicians are not allowed to disassemble the instrument.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com