The newly developed DFP 3000 compressed air filter test bench provides fully automated measurement o

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

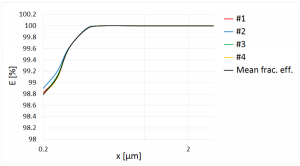

The Compressed Air Filter Test Bench is a fully automated system designed to measure the fractionation efficiency of compressed air filters at overpressures up to 7 bar. It provides highly accurate and reproducible testing that exceeds the requirements of ISO 12500. The system integrates the aerosol spectrometer, featuring a pressure-resistant aerosol sensor capable of measuring both feed and clean gases, ensuring precise determination of particle size and concentration without the need for dispersers or dilution. Additional filter funnels are available for testing plate media.

The Air Filter Test Bench is suitable for testing complete compressed air filters, evaluating filter media, and determining emissions during loading. It supports laboratories and production facilities in quality control, product development, and R&D activities. The system accommodates a wide range of aerosols, including oil-based and solid particles, and is capable of testing at elevated pressures up to 10 bar, providing results that are internationally comparable and compliant with multiple standards.

(1) EN 779 / ASHRAE 52.2 – General ventilation air filter testing

(2) DIN 33891 – Vacuum cleaner testing

(3) DIN 71460 – Automotive air filter testing

(4) HMT-1000 – Oil mist separator testing

(5) Scanning HEPA filter leak detection and efficiency measurement systems

1. Mobile testing unit with portable clean gas and easy filter replacement: The mobile clean gas unit allows for easy use of filter housings of different sizes.

2. Variable aerosol generation: Different dispersers are used for DEHS, dust, etc., enabling shorter measurement times, for example, by increasing aerosol concentration.

3. Wall-flow separator: A drain valve prevents oil particles separated from the feed gas pipe wall from entering the filter housing.

4. Light scattering aerosol spectrometer: Used for clear particle measurements directly at overpressures up to 10 bar; the integrated automatic adjustment of sampling volume flow rate under pressure changes ensures accurate measurement conditions.

5. flexible, pressure-resistant aerosol sensors can be used for direct particle measurement of feed gas and clean gas at overpressures up to 10 bar; thanks to the aerosol sensor (finely tuned for different aerosol concentrations in feed gas and clean gas, eliminating the need for a dilution system),

| Measurement range (dimensions) | 0.2 – 40 µm, 0.3 – 40 µm (at 7 barg) |

| Volume flow rate | 1 – 60 Nm3/h or 10 – 200 Nm3/h (other specifications available upon request) |

| Power supply | 115/230 V, 50/60 Hz |

| External dimensions | 300•130•60 mm (W•H•D) |

| Differential pressure measurement | 0 – 3.000 Pa |

| Aerosols | Liquid aerosol, e.g., DEHS |

| Aerosol concentration | Up to 106 particles/cm3 |

| Compressed air supply | 10 barg |

| Pressure | Relative to 1-7 barg |

The AGF 3000 is used in oil-based aerosol feed filters. Thanks to its special nozzle, this unit can generate a mass flow rate of up to 29 g/h. This minimizes loading time. The generator is equipped with an automatic refill system for oil supply.

• Solid particle testing up to 3 bar: RBG 1000 D

The RBG 1000 is used to measure fractionation efficiency and for dust feeding. Due to the use of interchangeable solid containers, the RBG 1000 P offers a particularly wide concentration range during diffusion.

The automated DFP 3000 features an integrated mass flow controller for regulating the volumetric flow rate through the aerosol generator and the dispersion volumetric flow rate. A pressure control valve located at the system inlet allows for automatic setting of the system pressure for filter testing. The filter testing software FTControl can perform filter tests individually and automatically using pre-programmed sequence programs for measurement procedures. The sequence programs allow for predefinition of two test parameters (including the main volumetric flow rate, system pressure, and aerosol generator control) and specification of the filter test sequence:

• Measure fractionation efficiency during feeding; pressure loss or measurement time can be pre-selected as a stop criterion.

• Define and display pressure loss and retention curves graphically and tabularly.

• Display particle size at separation efficiencies of 80% and 95%.

• Compare fractionation efficiency at different feeding stages.

• Reduce measurement time, for example, by increasing aerosol concentration.

Integrated sensor data, such as filter volumetric flow rate, system pressure, and differential pressure, are also automatically recorded during filter testing.

(1) Install the filter securely in the test section, ensuring proper sealing.

(2) Select the appropriate aerosol generator based on the type of filter and test method.

(3) Set the pressure and volumetric flow parameters via FTControl software.

(4) Monitor particle concentration and size in real time during testing.

(5) Automatically generate and save test reports upon completion.

(6) Perform routine cleaning and calibration of sensors, aerosol generators, and flow systems.

(7) Verify system integrity and functionality before testing.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com