True Body Weight Ingress Egress Tester is a unique machine that can be utilized to evaluate either a

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

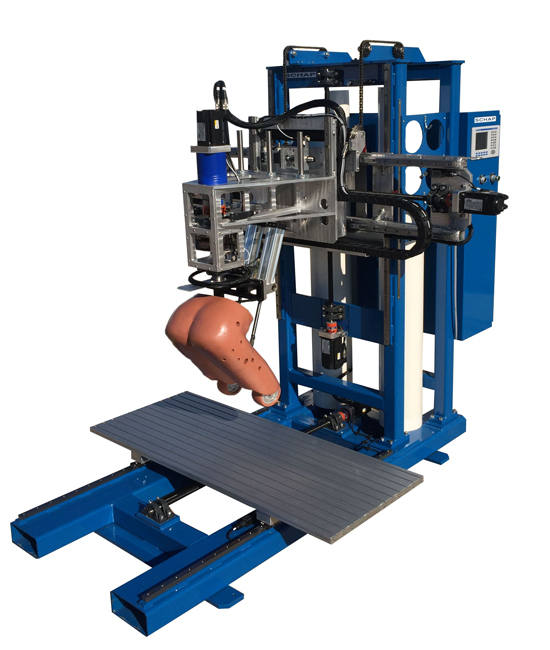

The True Body Weight Ingress/Egress Tester is a specialized machine designed to evaluate either a complete automotive seating system or individual seat components. It provides realistic simulation of human ingress and egress movements, including dynamic interaction with seat cushions, upholstery, and the underlying mechanical structure. The tester can even assess the wear and durability of the occupant’s clothing during repeated use.

The tester applies repeated motion sequences to the seat to simulate realistic human ingress and egress. Key evaluation criteria include:

Seat frame integrity (no cracks)

Foam deformation (none allowed)

Fabric and padding wear (minimal to none)

Maximum H-point variation within rated range

The tester can simulate vibration at 100 cycles per minute, with typical cycle counts of:

Seat cushion: 100.000 cycles

Backrest: 50.000 cycles

This ensures comprehensive fatigue and wear evaluation under true dynamic loading conditions.

SAE J826-2002 – Anthropomorphic Test Devices for Vehicle Seating Systems

QC/T 740-2017 – Automotive Seat Fatigue Test Standard

Industry standards for automotive seat ingress and egress durability

Four servo-electric motor-driven axes and three pneumatic functions for realistic movement.

Simulates in & out, right & left, up & down, rotation, free weight drop & recapture, and independent leg motion.

True body weight simulation (35–100kg) for realistic dynamic loading, including inertia effects.

Concurrent and programmable motion sequences for highly life-like testing.

Evaluates seat cushion, backrest, frame, foam, and fabric durability under repeated entry and exit cycles.

Adjustable test frequency, amplitude, and cycle count with automatic stop at the end of the test.

| Parameter | Specification | Notes |

|---|---|---|

| Dummy Model | 3D indenter, 50% SAE J826-2002 | Wrapped with 12mm foam and denim |

| Pressure Head Weight | 44.5 kg | Adjustable for different test scenarios |

| Horizontal Slide | ~25 mm into cushion | Inner rear first with 30° rotation |

| Load on Pressure Head | 445 N | Maintained during creep and exit cycles |

| Rotation Angle | 30° | Simulates realistic entry angle |

| Experimental Frequency | 4.5 cycles/min | Adjustable |

| Number of Experiments | 15.000 simulated ingress/egress cycles | — |

Pointer glass cover: Typically made of thickened tempered glass or acrylic, providing explosion-proof, scratch-resistant, and impact-resistant properties.

Washer: Located between the bottom of the scale and the platform, serving to absorb shock and stabilize the scale.

Zero-adjustment screw: Allows the pointer to accurately return to zero when unloaded by fine-tuning the balance system.

Weight weight: Used to measure weight.

Hook: Used to secure the weight.

Height ruler: Used to measure height.

Electronic height meter: Used to measure both height and weight.

Prepare the 3D dummy indenter according to SAE J826-2002 standards. Wrap with foam and denim, and add weight to simulate realistic human mass.

Secure the seat assembly on the test bench and adjust to design position.

Program the robot motion for simulated human entry/exit:

Horizontal slide of pressure head into seat, rotating 30°

Align center line of pressure head with seat center

Creep and stabilize pressure head within the seat

Maintain 445 N load while sinking into seat

Continue creep against backrest at 30°

Maintain 445 N load as pressure head is halfway out

Slide along seat cushion edges during exit, simulating edge indentation

Start the test cycle; machine automatically repeats motions at set frequency.

Stop automatically after 15.000 simulated cycles and inspect seat for damage.

Ensure proper calibration of servo-electric axes and pneumatic actuators.

Check dummy and pressure head integrity before testing.

Maintain and inspect all mechanical and pneumatic components regularly.

Emergency stop and overload protection are built-in for operator safety.

Clean and lubricate moving parts as per manufacturer instructions.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com