Arc Resistance Tester is a special instrument necessary for simulated safety test items specified in

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

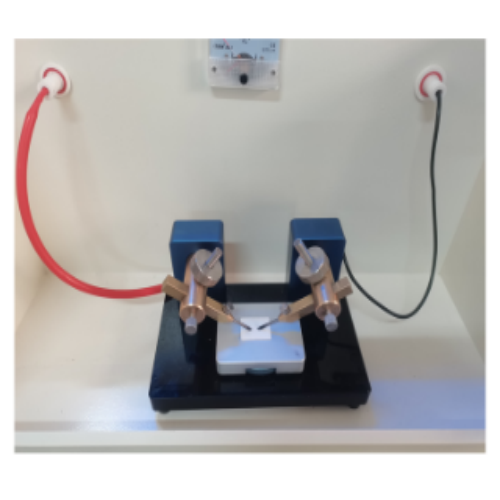

Arc Resistance Tester is a special instrument necessary for simulated safety test items specified in GB1411. IEC61621. ASTMC495. UL746A and other standards.

Arc resistance test system is a high-precision equipment specially developed for the test surface of electrical insulation materials, suitable for electrical insulation materials, plastics, films, resins, mica, ceramics, glass, insulating paints and other insulating materials arc resistance performance assessment, can also be applied to product testing and new materials electrical performance research purposes.

Comply with the standard:

GB/T1411-2002 dry solid insulating material resistance to high voltage, small current arc discharge test (equivalent to IEC 61621-1997) and ASTM D495 and other standards; in line with UL 746A and other test methods

Functional principle:

Insulating materials to resist deterioration caused by high-voltage arc action, usually with a standard arc flame on the surface of the material caused by charring to the surface conductivity and the arc disappeared the time required to express the unit of seconds in the plate specimen plus two separated by a certain distance from the tungsten electrodes, depending on the need for high-frequency high-voltage current between the two poles to produce an arc, initially intermittent time is gradually shortened, and finally for the continuous arc and gradually increase the current, the material The material is subjected to gradually harsh arc conditions and eventually cause damage. Arc resistance for high-voltage switch or low-voltage high-current switch insulating materials have important significance, because in the switch opening and closing will often be subjected to arc action, only good arc resistance materials can be selected.

In electrical and electronic equipment within the insulating material when it is exposed to high voltage, small current arc discharge, between them to withstand the initial difference in the immediate surface damage occurs, arc discharge caused by local thermal and chemical decomposition and corrosion and ultimately in the insulating material on the formation of conductive channels, when the formation of conductive channels within the material under test, it can be determined that the material has failed.

Equipment parameters:

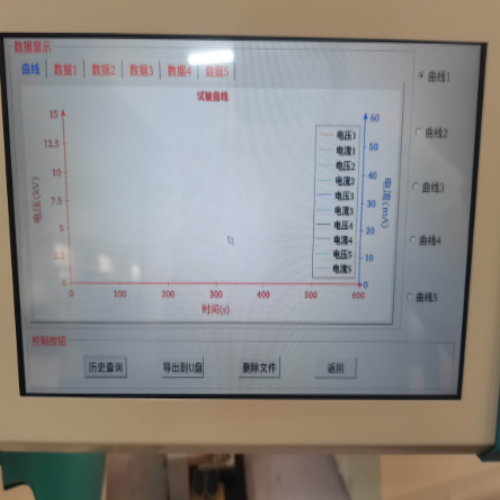

1. Arc through the time error: 1/8s through 7/8s break ± 5ms, the rest of the program is better than ± 1ms

2. Regulator capacity: 1kVA

3. Rated test voltage: 12.5kV

4.Maximum test voltage: 15.0kV

5. Test voltage accuracy: <1.0%

6. Accuracy of current measurement: <1.0%

7. Electrode pressure on specimen: (0.5±0.05)N

8. Electrode material: tungsten rod

9. Electrode distance: (6.35±0.1)mm

10.Ambient temperature: (23±2)℃.

11.Ambient Humidity: (50±5)%

12. Power supply: 220V±5% 50Hz 10A

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com