Measures paper/board compression strength (RCT, ECT, FCT, etc.) per standards.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

ISO 12192 TAPPI T 822 ISO 3035 EN 23035 TAPPI T 825 ISO 3037 EN ISO 3037 TAPPI T 811 TAPPI T 838 TAPPI T 839 ISO 7263 BS EN ISO 7263 TAPPI T 809 ISO 9895 TAPPI T 826 DIN 54518 BS 7325 ASTM D7027-05 ASTM D5178 Other relevant industry standards (e.g., for CCT, PAT, SCT)

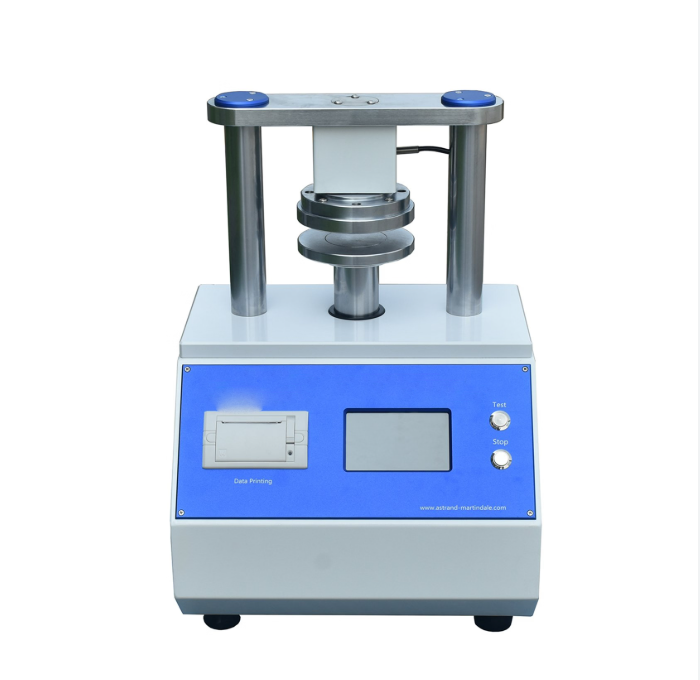

The Paper Ring Compression Tester applies a compressive load to a prepared sample of paper or paperboard and measures the maximum force the sample can withstand before buckling or crushing. For the Ring Crush Test (RCT), a strip of paperboard is formed into a ring and placed in a special holder to prevent buckling before the material itself fails under edgewise compression.

Paper and paperboard manufacturing for quality control and product development.

Corrugated board production and box manufacturing to predict box performance and optimize material usage.

Packaging research and development laboratories.

Quality inspection and certification bodies for paper and packaging materials.

Essential for Packaging Quality Control: Provides critical data for predicting the stacking strength and overall compression performance of corrugated boxes.

Measures Fundamental Strength Property: Quantifies the edgewise compression resistance of paper and paperboard, a key material characteristic.

Standard Compliant: Designed to perform tests according to numerous international and national standards (ISO, TAPPI, EN, etc.) for paper and board compression tests.

Versatile Testing Capabilities: Many models can perform multiple types of compression tests (RCT, ECT, FCT, SCT, CMT, PAT) with appropriate fixtures.

Objective and Quantitative Results: Provides a numerical value for compression strength.

Automated Operation: Modern testers often feature automated test cycles with digital display and recording of peak load.

Improved Production Efficiency: Helps optimize material selection and identify process issues affecting compression strength.

Based on typical Paper Ring Compression Testers and related multi-functional compression testers:

Electrically driven compression mechanism with two parallel platens.

Capability to apply a compressive load at a constant rate of descent (standard speed is often 12.5 ± 2.5 mm/min).

Load cell to measure the applied compressive force.

Digital display showing real-time load and capturing the peak load at failure.

Capability to perform Ring Crush Test (RCT) using a specific fixture and sample holder (e.g., for 152 mm x 12.7 mm samples).

Often includes interchangeable fixtures for performing other compression tests such as Edge Crush Test (ECT), Flat Crush Test (FCT), Short Column Test (SCT), etc.

Microprocessor or PLC control system for test control, data processing, and display.

Automatic detection and holding of the peak load value.

Overtravel protection and safety limit switches.

Quick return function for the compression platen.

Calibration facility (often integrated).

Robust benchtop design.

Some models offer computer connectivity and software for data analysis, reporting, and test control.

Force Measurement range | 0-3000N |

Resolution | 1N |

Test Speed | (12.5±2.5) mm/min (ECT, RCT, FCT, CMT, CCT, PAT) |

Parallelism between upper and lower plate | <0.05mm |

Dimension | 350×370×530mm |

Weight | 45Kg |

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com