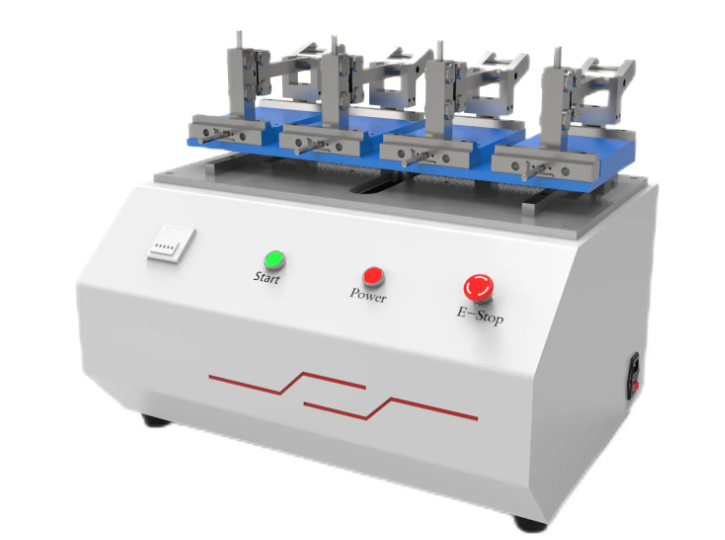

The 4-Station Leather Friction Color Fastness Tester is a specialized laboratory instrument designed

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

This instrument is used to test the rub fastness of leather surfaces. It evaluates color transfer by determining the degree of "color loss" from the leather surface or coating and the degree of staining on the wool felt. During the test, a dry or wet white wool felt is wrapped around the rubbing surface, and then rubbed back and forth against the test specimen clamped to the test bench. Both dry and wet testing methods are available.

1. Leather Product Quality Control

This involves colorfastness testing for leather uppers, linings, garments, bags, and other products.

It ensures that leather products maintain a good appearance and performance during long-term use, meeting consumer demands.

2. New Product Development

This involves evaluating the rub fastness performance of new leather materials to provide a basis for product improvement.

It optimizes leather dyeing processes and enhances the market competitiveness of products.

3. Third-Party Testing Institutions

This provides independent colorfastness testing services for leather product manufacturers.

It ensures that products meet relevant standards or customer requirements, increasing customer trust.

The tester adheres to global colorfastness and material testing protocols, including:

ISO 11640 (Leather – Color fastness to rubbing)

SATRA TM170 (Standard method for color fastness to rubbing)

AATCC 8 (Colorfastness to Crocking: AATCC Crockmeter Method)

ISO 105-X12 (Textiles – Color fastness to rubbing)

GB/T 3920 (China’s national standard for color fastness to rubbing)

These standards ensure consistent evaluation of color transfer, dye adhesion, and surface durability.

1. Dry and Wet Friction Test Supports dry or wet wool felt as the friction medium, simulating friction conditions under different environments.

2. Multi-Station Parallel Testing The four-station design allows for simultaneous testing of four samples, improving testing efficiency.

3. Damage and Discoloration Assessment The friction color fastness grade of the leather is evaluated based on the degree of staining on the wool felt after friction and the discoloration of the leather itself.

| Parameter | Specification |

|---|---|

| Number of Stations | 4 (simultaneous testing of 4 samples) |

| Friction Head Load | 9 N (standard; adjustable 5–15 N for custom tests) |

| Stroke Length | 100 mm (adjustable) |

| Friction Speed | 60 ± 2 cycles/min (1 cycle = 1 double stroke) |

| Sample Dimensions | 140 × 50 mm (standard leather/textile swatches) |

| Abrading Fabric | Standardized cotton cloth (e.g., Crockmeter cloth per ISO 105-F10) |

| Power Supply | 220V/50Hz, 60W |

| Dimensions | 500 × 350 × 300 mm (L × W × H) |

Standard accessories: Core friction media (wool/cotton rubbing pads/cloths), fixing parts (sample/friction media clamps), standard weights, LCD counter, gray scale cards, power cord, user manual, certificate of conformity, warranty card, and calibration fabrics (for some models).

Optional accessories:Additional rubbing media, small rubber pads, heating station accessories, metal feet, pre-tension adjustment clamps, light box, vacuum dryer & pump, and liner sandpaper.

1. Preparation

Select the appropriate friction head, felt pad, and sample clamping device, ensuring all components are clean and free from contamination.

Securely and evenly attach the felt pad to the surface of the friction hammer, avoiding wrinkles that could affect the test results.

2. Sample Installation

Cut the leather sample to be tested according to the specified dimensions and shape.

Securely and evenly fix the sample to the sample clamping device, ensuring that the sample does not move or deform during the test.

For stretchable samples, stretch the sample by a certain percentage (e.g., 10%) along the friction direction and fix it to the clamp.

3. Parameter Setting

Set parameters such as the number of friction cycles, pressure, and friction speed according to the test standard or customer requirements.

The number of friction cycles is usually selected from 5. 10. 20. 50. 100. 200. 500. etc., to cover different testing needs.

4. Starting the Test

Start the testing machine. The motor will drive the friction hammer to perform reciprocating friction on the leather sample under the specified conditions.

During the friction process, the friction hammer will apply a certain pressure and friction force to the leather surface, simulating the friction conditions in actual use.

5. Observation and Recording

During the test, observe the color changes on the sample surface and record the test data promptly.

At the same time, observe the color change of the felt pad to evaluate the friction color fastness of the leather sample.

6. Scoring and Rating

After the test, based on the observed color changes, refer to relevant standards or scoring criteria (such as the gray scale) to score or rate the friction color fastness of the leather.

The scoring result will directly reflect the color fastness performance of the leather sample.

YouTube video introduction:https://www.youtube.com/watch?v=4NY5zuHI_5k

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com