Product NameFabric Static Stress Resistance TesterApplication ScopeIt is used for testing the elbow

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The fabric inductive electrostatic tester, under laboratory conditions, is suitable for determining the electrostatic properties of fibers, yarns, fabrics, carpets, decorative fabrics, and other types of fabrics or various sheet-like finished products. The main unit of the instrument consists of a corona discharge device and a probe detector. Using a given high-voltage electric field, the fabric is discharged for a fixed period of time, inducing static electricity.

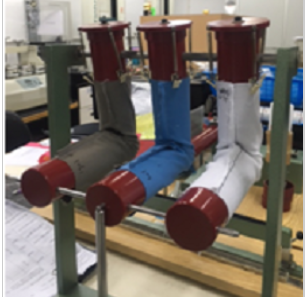

It is used for testing the elbow static stress deformation of textiles such as woven fabrics or knitted fabrics. The testing instrument includes an elbow fabric static stress resistance tester, an elbow fabric protrusion height measuring instrument, a sample preparation template, etc.

DIN 53860 - 1: Inspection of textiles - Inspection of planar fabric sac-like protrusions - Part 1: Static stress bend tube test method

1. The frame is made of high-quality aluminum alloy, which is relatively lightweight.

2. Equipped with LED lighting source, with high illuminance, clear imaging and easy identification.

3. Ball joint connection, with low sliding friction and smooth movement.

4. Hinged connection for easy clamping of samples.

5. The measuring arm is made of high-quality non-metallic materials, which is light and easy to operate.

| Parameter | Description |

|---|---|

| Angle of the upper test arm relative to the vertical line | 10 degrees |

| Spring stiffness | 149N/M (meeting the standard requirement of 150N/M ± 30N/M) |

| Wire diameter | 0.3mm |

| Diameter | 3mm |

| Length of the upper test arm | 250mm |

| Length of the lower test arm | 300mm |

| Connection method | Ball joint connection |

| Lighting source | LED with a power of 20W |

| Projection method | Optical imaging with a resolution of 1mm |

| Measuring arm | Hinged connection for easy clamping of samples |

| Dimensions - Static stress experiment part | 600mm×600mm×800mm |

| Dimensions - Projection measurement part | 400×600×600mm |

| Power supply | AC220V 50Hz |

The core components of a fabric electrostatic stress resistance tester (taking a fabric inductive electrostatic tester as an example) include a corona discharge device, probe detector, test electrodes, high-resistivity meter, insulating platform, Faraday cylinder, capacitor, and charge meter. Some models also include an automatic control box and computer testing system for data recording and analysis. The following are detailed descriptions:

Corona Discharge Device: Used to simulate a high-voltage electric field environment, charging the fabric; it is a key component for testing electrostatic performance.

Probe Detector: Detects the instantaneous peak value, half-life, and residual charge on the fabric, providing direct digital display.

Test Electrodes: Used to measure the surface resistivity, vertical resistivity, and point-to-point resistance of the fabric. The electrode material is mostly stainless steel to ensure measurement accuracy.

High-Resistivity Meter: Works with the test electrodes to accurately measure the resistivity of the fabric and evaluate its antistatic performance.

Insulated Platform: Provides a stable testing platform, preventing external interference and ensuring the accuracy of test results.

Faraday Cylinder: Used in the charge meter to accurately measure the potential of the charged sample and perform data conversion. Capacitor: Together with a Faraday cylinder and potentiometer, forms a potential measuring device for accurate measurement in a charge measuring instrument.

Charge Meter: Displays measurement results, providing accurate readings of the charge quantity.

Automatic Control Box: Equipped in some models, used to control the testing process, enabling both timing and constant voltage testing modes.

Computerized Testing System: Equipped in some models, used for data recording and analysis, improving testing efficiency and accuracy.

The operation method of the fabric electrostatic stress resistance tester includes the following steps:

Preparation and Calibration: Confirm that the instrument is within its calibration period, connect the power supply or install batteries, connect the ground wire to a suitable grounding point, and calibrate according to the operation manual to ensure test accuracy.

Environmental Setup: Place the instrument in a room-temperature, dry, windless environment free from strong magnetic field interference. Avoid humidity or strong winds affecting the test results.

Test Location Selection: Determine the location where electrostatic field strength or potential difference needs to be measured, such as the fabric surface, and place the probe or sensor.

Startup and Parameter Setting: Turn on the instrument power and set the test parameters according to the operation manual, such as frequency and distance. Some instruments require selecting the test method (e.g., constant voltage half-life determination, timed electrostatic measurement method).

Measurement: Place the probe or sensor at the test location, wait for stabilization, and read the measurement results. Some instruments can automatically record data or generate test reports.

Data Analysis and Recording: Analyze the measured data as needed, such as calculating the average, maximum, and minimum values, and record the test results.

Safe operation and maintenance: Follow safety procedures during testing, wear anti-static gloves, and avoid direct contact with probes or sensors; turn off the power after testing, and clean and maintain the instrument in a timely manner to ensure it is in good condition.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com