Product features:1. Strictly in accordance with the standard design of the contact area and measurem

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

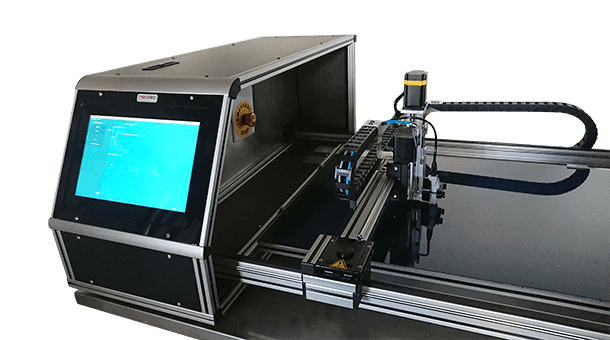

The Coating Thickness Gauge is a high-precision contact-type thickness measuring instrument designed for accurate determination of thickness for films, papers, foils, nonwovens, and sheet materials.

The instrument strictly follows standardized contact area and measuring pressure requirements to ensure reliable and repeatable results, while also supporting non-standard customization to meet special testing needs.

With automatic lifting and lowering of the measuring head, real-time statistical analysis, and touchscreen operation, the system effectively reduces human-induced measurement errors and is suitable for both laboratory testing and production quality control.

Basic Applications

(1) Plastic films (packaging film, agricultural film, functional films)

(2) Paper products (paperboard, corrugated board, diaphragm paper)

(3) Foils (aluminum foil, copper foil, composite foil materials)

(4) Silicon sheets and metal sheets

(5) Solid electrical insulating materials

(6) Textile materials and coated fabrics

(7) Nonwoven products (diapers, sanitary napkins, medical nonwovens)

Extended Applications (special accessories or customization required)

(1) Thick films and sheets with extended measuring range (up to 5 mm or 10 mm)

(2) Curved or special-shaped samples using customized curved measuring heads

(3) R&D testing for multilayer composite materials

(1) GB/T 6672 – Determination of Thickness of Plastic Film and Sheet

(2) GB/T 451.3 – Paper and Board — Thickness Determination

(3) GB/T 6547 – Corrugated Board — Thickness Measurement

(4) ISO 4593 – Plastics — Film and Sheet — Thickness Measurement

(5) ISO 534 – Paper and Board — Thickness, Density and Specific Volume

(6) ISO 3034 – Corrugated Fibreboard — Thickness Measurement

(7) ASTM D374 – Thickness of Solid Electrical Insulating Materials

(8) ASTM D1777 – Thickness of Textile Materials

(9) TAPPI T411 – Thickness (Caliper) of Paper, Paperboard, and Combined Board

(10) JIS K6250 – Rubber and Plastic — Thickness Measurement

(11) JIS K6783 – Plastic Films and Sheets — Thickness

(12) JIS Z1702 – Packaging Materials — Thickness Testing

(13) BS 3983 – Measurement of Thickness of Plastic Films

(14) BS 4817 – Thickness Measurement of Sheet Materials

(1) Designed strictly in accordance with standard contact area and measuring pressure requirements

(2) Automatic lifting and lowering of the measuring head to eliminate operator-induced errors

(3) Supports both automatic and manual measurement modes

(4) Optional automatic injection system with adjustable injection step, measuring points, and injection speed

(5) Real-time display of maximum value, minimum value, average value, and standard deviation

(6) Standard calibration blocks supplied to ensure accuracy and data consistency

(7) Supports real-time data display, automatic statistics, and report printing

(8) 5-inch touchscreen interface for intuitive operation and data viewing

(9) Standard USB interface for easy data transfer to external computers

| Parameter | Specification |

|---|---|

| Measuring Range (Standard) | 0–2 mm |

| Measuring Range (Optional) | 0–5 mm / 0–10 mm |

| Resolution | 0.1 μm |

| Measuring Pressure | 0.5–1.0 N |

| Measuring Diameter | Φ3 mm – Φ10 mm (Optional) |

| Platform Area | 520 mm × 390 mm (Customizable) |

| Automatic Injection Speed | 0.1–99.9 mm/s |

| Display | 5-inch color touchscreen |

| Data Interface | USB |

| Power Supply | AC 220 V, 50 Hz |

| Overall Dimensions (L × W × H) | 620 × 415 × 350 mm |

| Net Weight | 40 kg |

| Customization | Contact diameter, pressure, range, and fixtures customizable |

(1) Standard calibration measuring blocks

(2) Standard flat measuring head

(3) Optional curved measuring head

(4) USB data cable

(5) Power cable

(1) Power on the instrument and perform calibration using the standard block

(2) Select automatic or manual measurement mode

(3) Place the sample flat on the measuring platform

(4) Set measuring parameters such as pressure and injection speed (if applicable)

(5) Start measurement and allow the measuring head to descend automatically

(6) Review real-time results and statistical analysis on the touchscreen

(7) Export or print test data as required

(1) Regularly clean the measuring head and platform surface

(2) Periodically verify calibration using standard blocks

(3) Avoid dust, vibration, and corrosive environments

(4) Do not exceed the specified measuring pressure and range

(5) Perform routine inspection of mechanical and electrical components

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com