Time: Popularity:0times

Paper, as a carrier of information and cultural heritage, and a fundamental material in the modern packaging industry, directly affects the quality of printed materials, the protective function of packaging, and the lifespan of products. Among the many physical indicators for measuring paper quality, "stiffness" is a comprehensive concept. It does not refer to a single characteristic but encompasses a range of mechanical properties, including tensile strength, folding endurance, tear resistance, and stiffness.

Paper stiffness testing is a method for measuring the surface hardness of paper. It can assess the strength and durability of paper, thereby determining its reliability in different applications. Hardness testing is commonly used in industries that manufacture and process paper, such as paper production, printing, and packaging.

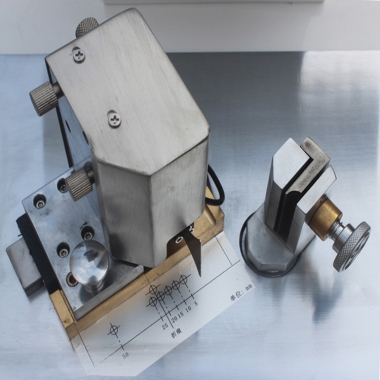

A paper hardness tester is an instrument used to measure the stiffness or strength of paper or paperboard. It is commonly used to evaluate the physical properties of paper, such as surface hardness, stiffness, and compressive strength.

Tensile strength refers to the maximum tensile force that a unit width of paper or paperboard can withstand before breaking. It directly reflects the internal fiber bonding strength and the strength of the fibers themselves.

Detailed Explanation of Method and Principle: This method requires the preparation of a standard strip specimen (usually 15 mm wide and long enough to be firmly clamped by the upper and lower jaws of a tensile testing machine). The specimen is placed on the electronic tensile testing machine, ensuring that its axis is aligned with the direction of the tensile force. After starting the equipment, the lower jaw descends at a specified constant rate (e.g., mm/min), applying a gradually increasing tensile force to the specimen until it breaks.

The instrument automatically records and outputs the tensile strength (kN/m), elongation at break (%), and tensile energy absorption (T.E.A., J/m²). A higher tensile strength value indicates that the paper is "tougher" and less likely to break. Elongation at break reflects the paper's flexibility; paper with high elongation can deform more under stress without breaking immediately. Tensile energy absorption is a comprehensive indicator, representing the total energy required to break a unit area of the sample, and is particularly important for assessing the impact resistance of packaging paper during drops. The test must measure the paper's longitudinal and transverse directions separately, as the orientation of paper fibers causes significant differences in strength in these two directions.

Folding endurance describes the paper's ability to resist repeated folding fatigue under a certain tension. This test is crucial for materials that require repeated folding, such as banknote paper, map paper, and book cover paper.

The most commonly used instrument is the MIT folding endurance tester. Prepare a sample with a width of 15 mm and a long diameter of at least 140 mm. During testing, the sample is vertically clamped between two opposing grips, with an initial tension (e.g., 9.81 N) applied to its lower end. The instrument drives the grips, causing the sample to fold back and forth within a 135° arc. Each back-and-forth movement of the folding head is counted as one fold.

The instrument runs continuously until the sample completely breaks, automatically recording the final number of double folds. This value directly reflects the paper's fatigue life. A higher value indicates stronger fiber bonding and better flexibility, enabling it to withstand more repeated folds. The test typically requires repeating at least five samples, and the average value is taken as the final result to ensure data representativeness.

Using an Allimentdorf tear tester, an instantaneous tearing force is applied after fixing the sample, and the required energy value is measured. It is necessary to distinguish between initial tear strength and extended tear strength.

Using a Tiber stiffness tester, the sample is placed on a platform at a specific angle, and its resistance to bending deformation is measured. The result is expressed in millinewtons per meter (mN·m).

Paper manufacturers can use a paper stiffness tester to test the stiffness and strength of the paper or paperboard they produce to ensure that the product meets quality standards and specifications.

The printing industry, packaging industry, or other users of paper can use this instrument to check the stiffness and stiffness of the paper or paperboard they purchase to ensure that it is suitable for specific application needs, such as printing, packaging, or manufacturing.

When developing new paper products, optimizing production processes, or improving raw materials, a stiffness tester can be used to evaluate the influence of different factors on paper stiffness and stiffness to improve product performance.

Ensure the paper stiffness tester is in working order and perform necessary calibration and maintenance to ensure the accuracy of the test results.

Prepare the paper or paperboard sample to be tested and cut it into the specified shape and size according to the testing standards. Typically, the sample needs to be cut into a rectangle with specific dimensions.

Select the required test parameters, such as test speed and test pressure. These parameters may vary depending on the test standard and the type of sample being measured.

Place the sample in the test area of the paper hardness tester, ensuring it is properly supported and positioned to maintain stability during testing.

Start the test instrument and perform the test according to the selected parameters. The instrument will apply pressure to the sample, measuring parameters such as hardness, stiffness, or compressive strength.

The instrument will automatically record the test data, including the measurement results of hardness, stiffness, or compressive strength. This data is typically expressed in specific units, such as Newtons (N) or Pascals (Pa).

Based on the test results, evaluate whether the hardness and strength of the paper or paperboard meet the requirements, or for research and development purposes. A report can be generated to record the results.

As a widely used product, the quality of paper directly affects the consumer's experience. Paper that meets national standards guarantees the quality of its physical, chemical, and printability properties, thus providing consumers with a reliable product. For example, for book paper, good paper quality ensures clear printing, comfortable reading, and reduces the risk of paper damage or yellowing. For packaging paper, standard-compliant paper effectively protects products from damage during transportation and storage.

National standards for paper inspection and testing provide clear quality standards and testing methods for paper manufacturers and distributors, helping to regulate market order. Companies must produce and test according to national standards to ensure product quality; otherwise, they will face penalties from market regulators. At the same time, national standards provide consumers with a basis for judging paper quality, enabling them to make more rational product choices and promoting healthy market competition.

The formulation and implementation of national standards help promote technological progress and industrial upgrading in the paper industry. To meet the requirements of national standards, companies need to continuously improve production processes and enhance technological levels, thereby improving product quality and competitiveness. Furthermore, national standards provide direction and guidance for industry development, promoting the sustainable development of the paper industry.

Paper stiffness is not a vague sensory concept, but a scientific system comprised of multiple quantifiable mechanical properties such as tensile strength, folding endurance, tear resistance, and stiffness. By strictly adhering to the testing methods specified in the GB/T series of national standards, the industry can achieve precise control over paper quality.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com