Time: Popularity:0times

Many resin products we use in our daily lives, such as smartphones and car bumpers, require impact resistance. Some of the simplest methods used to determine the impact resistance and toughness of resins are the Charpy and Izod impact tests. These are pendulum impact tests in which a high-speed impact is applied to the test specimen.

The Izod and Charpy impact tests are two commonly used methods for evaluating the impact strength of materials. Both the Charpy and Izod impact tests measure the energy a material can absorb during fracture, thus helping to assess its toughness. However, the main difference between the Izod and Charpy impact tests lies in the specimen position and notch orientation.

In the Izod impact test, the specimen is positioned vertically with the notch facing the impactor, while in the Charpy impact test, the specimen is positioned horizontally. This results in a different stress distribution during impact.

Understanding the difference between the Charpy and Izod impact tests is crucial for selecting the appropriate quality testing method. When comparing the Charpy and Izod impact tests, the industry typically chooses based on application requirements and international standards. The Izod impact test reliably assesses a material's durability under sudden loading conditions.

Both Izod and Charpy impact tests focus on measuring the total energy a material can absorb before breaking. This energy absorption is directly related to the material's brittleness or ductility. Materials that absorb a large amount of energy before breaking are generally more ductile. Materials that absorb little energy and break easily are more brittle.

In an Izod impact test, the specimen is positioned vertically with the notch facing the pendulum. This test uses only a V-notch and measures a material's ability to withstand a single, high-energy impact. This makes the Izod impact test particularly suitable for testing brittle materials such as plastics and certain lightweight metals.

The pendulum swings downward and strikes the upper end of the specimen, recording the energy absorbed during the impact. The Izod impact test is popular in North America, particularly in industries that rely on plastics and polymers.

The Charpy impact test, on the other hand, uses a horizontal specimen with the notch facing away from the pendulum. Compared to the cantilever beam impact test, the Charpy impact tester applies a more concentrated, smaller energy load, making it suitable for evaluating the energy that ductile materials, such as metals, can absorb before fracture.

Working Principle

In addition to sufficient strength and ductility, metal materials must also possess sufficient toughness during use. Toughness refers to the material's ability to absorb energy during elastic and plastic deformations, as well as fracture.

The Charpy impact test is a traditional mechanical property testing method that measures the toughness of metallic materials by striking the notch of a specimen with a pendulum. Due to its simple specimen preparation, short test cycle, and sensitivity to material structure, this method is widely used to evaluate the resistance of metallic materials to brittle fracture under impact loading. Rapid-load equipment in engineering applications, such as automotive and aviation, often uses this method as a material screening tool. Internationally, several standards exist, including GB/T 229. ASTM E23. and EN ISO 148-1. Recent research from 2024 shows that when specimen thickness is less than 2.5mm, support shims can significantly affect test results.

The Charpy V-notch impact test is an important material property test method, playing a crucial role in assessing a material's toughness and fracture resistance. Through rigorous sample preparation, temperature control, and impact testing, it accurately reflects the material's performance in real-world applications.

Izod Impact

Notched Izod impact is a single-point test used to measure a material's resistance to pendulum impact. Izod impact is defined as the kinetic energy required to initiate fracture and continue fracture until the specimen breaks. Izod specimens are notched to prevent deformation during impact. This test can be used as a quick and simple quality control check to determine if a material meets specific impact properties or to compare the general toughness of materials.

The choice between Izod and Charpy impact testing depends largely on the material and the industry standards you adhere to. Different industries use different methods based on the types of materials used and the specific standards they must meet.

The Izod impact test is widely used to test the toughness of plastics and brittle materials. For example, plastic product manufacturers often rely on this method to ensure their products can withstand sudden impacts during use.

This test can help you understand how plastic parts perform under conditions such as accidental drops or collisions. In North America, the Izod impact test is widely used due to its familiarity and relevance to the lightweight materials industry.

In contrast, the Charpy impact test is typically used in industries that process metals, particularly where durability and toughness are crucial. This test is widely used in the automotive, aerospace, and construction industries to evaluate the ability of materials like steel to withstand sudden, severe impacts.

For example, in automotive design, engineers often use the Charpy V-notch impact test to evaluate the safety and reliability of metal components such as vehicle frames and body panels. The Charpy impact tester applies a concentrated energy load to the material, simulating real-world conditions where metals might be subjected to significant stress or external forces.

When choosing the right impact tester for your needs, you need to consider the following points.

Most importantly, the material you are testing. Impact testers are designed to test different materials, so you need to make sure you purchase one specifically designed for the specific material you want to test.

Another factor to consider is the size of the sample you want to test. Some impact testers can only test small samples, while others can accommodate larger samples.

Finally, you need to determine what type of data you need from your test. Some impact testers only provide basic data, while others can provide more detailed information. After considering all of these factors, you should be able to narrow down your choices and select the impact tester that best suits your needs.

| Comparison Dimensions | Charpy Impact Test | Izod Impact Test |

|---|---|---|

| Specimen Positioning | Horizontal, like a beam. | Vertical, like a cantilever. |

| Notch Direction | Notch facing away from the pendulum impact surface. | Notch facing toward the pendulum impact surface. |

| Main Test Materials | Metals (such as steel), ductile materials. | Plastics, polymers, and brittle materials. |

| Impact Energy Characteristics | Applies a more concentrated, smaller energy load. | Measures the ability to withstand a single, high-energy impact. |

| Stress Distribution | The specimen is unsupported at both ends, generating bending stress during impact. | The specimen is fixed at one end, generating cantilever bending stress during impact. |

| Main Application Industries | Automotive, aerospace, and construction (evaluating metal structural components). | Plastics (such as electronic product housings and automotive plastic parts). |

| Popular Regions | Widely used in the metals industry in Europe and globally. | In North America, it is particularly popular in the plastics industry. |

| Standard Examples | GB/T 229. ASTM E23. EN ISO 148-1 | Mainly follow ASTM standards (e.g., ASTM D256 for plastics) |

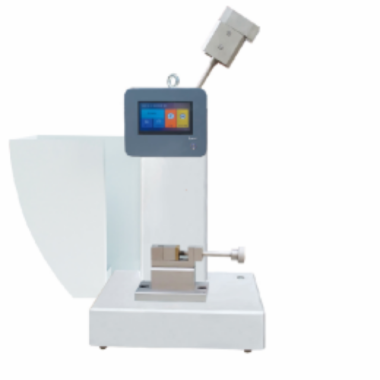

PLC liquid crystal touch impact testing machine (simple suspension)

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com