Aluminum refining thermal vehicle plays a crucial role in alloy production, primarily removing oxide

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

Working Principle:

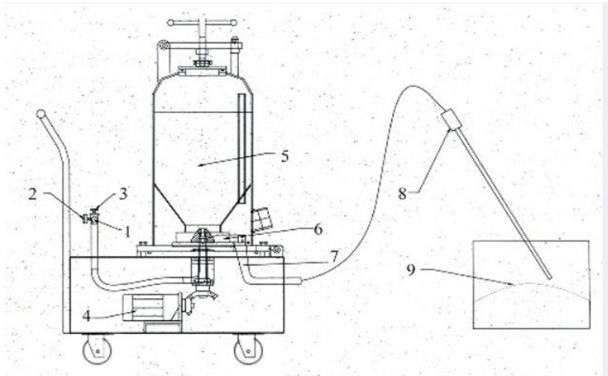

Aluminum refining spraying vehicle plays a crucial role in alloy production, primarily removing oxides and other impurities from molten aluminum. It is termed a composite refiner because it utilizes a mixture of solid particulate refining agents and inert gas delivered into the molten aluminum via a powder injection tube. Operators continuously maneuver the tube to optimize refining efficiency.

Equipment Features:

Technical Specifications:

Application Scope:

Suitable for various pool-type aluminum melting furnaces.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com