The Thermal Protective Performance (TPP) Test Device was developed to measure the time elapsed for c

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

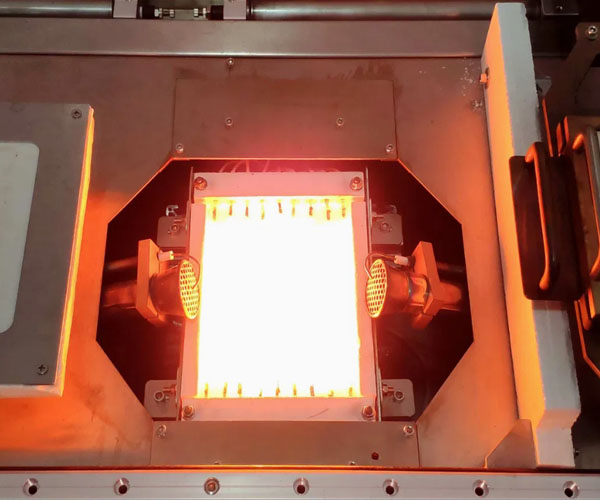

The Thermal Protective Performance Tester (TPP) is designed to evaluate the thermal insulation and burn-injury protection capability of flame-retardant fabrics used in firefighter suits, protective gloves, workwear, and industrial safety clothing. By exposing specimens to controlled radiant and/or convective heat, the instrument measures the heat energy transferred through the fabric and determines the time to second-degree burn based on the Stoll curve. This provides a highly accurate and scientific assessment of thermal protection performance for PPE material development, certification, and quality control.

The thermal protection performance (TPP) tester is mainly used to test the thermal insulation properties of horizontally placed flame retardant protective clothing fabrics exposed to radiant and convective heat sources.measuring the resulting damage to human skin.

(1) BS EN ISO 6942 – Protective clothing – Protection against heat and flame – Method of test for the determination of heat transfer on exposure to a heat source

(2) EN 366 – Protective clothing against heat and flame – Resistance of materials to contact heat

(3) EN 407 – Protective gloves against thermal risks (heat and/or fire)

(4) ISO 11612 – Protective clothing – Clothing to protect against heat and flame

(5) ASTM F1939 – Standard Test Method for Evaluation of Thermal Protective Performance of Materials for Clothing

(6) ASTM F2702 – Standard Test Method for Heat Transfer and Thermal Protective Performance of Flame Resistant Clothing Materials Using a Thermal Protective Performance Tester

(7) NFPA 1971 – Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting

(8) NFPA 2112 – Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire

(9) GB 38543 – Technical Specification for Fire Protection of Workwear for Industrial Personnel

(10) GB/T 38306 – Test Method for Thermal Protective Performance of Flame Retardant Protective Clothing

Under exposure to a specified heat flux, the time to second-degree burns is derived from the intersection point of the response curve (temperature rise curve of the calorimetric sensor) and the human tissue tolerance curve (Stoll curve). The higher the product of the heat flux level and the time to second-degree burns, the stronger the thermal protective performance of the fabric.

Standard calorimeter mounting block.

PLC control system provides stable and fast testing performance.

Analysis software with user friendly interface is easy to use and installed Stoll curve model internally.

Compact structure design reduces the requirements of fume hood.

Evaluates the potential for skin burns associated with a fabric’s ability to block convective and

radiant heat penetration

Automatic test operation provides repeatable and precise results

Independently controlled radiant heat source and convective heat source

Supports up to three copper disk calorimeter sensor assemblies

Integrated air-cooled sensor stand quickly prepares calorimeter sensor for next test

Water-cooled shutter is pneumatically actuated for precise exposure control

Automatically predicts time to second degree burn, with results shown as a real-time numerical and graphical display of sample performance compared to the Empirical Performance Curve

Small and portable, the TPP test device fits in most standard fume hood

| Heat Flux Measurement Range | 0–167 kW/m² |

| Heat Flux Measurement Accuracy | ±2 kW/m² |

| Specimen Irradiated Size | ≥200mm*200mm, for testing flame-retardant protective clothing, fire-fighting suits and protective gloves |

| Convection Heat Source | 2 Merkel lamps (Heat flux: up to 60 kW/m²; Radiant heat flux: up to 40 kW/m²) |

| Rotor Propane Gas Flowmeter | Provides precise, stable propane flow for the burner |

| Radiant Heat Source | 9pcs of 500W infrared quartz lamps (proportional power control for 0–30 kW/m²radiant heat flux) |

| ASTM F2703 Copper Calorimeter | Accuracy ±3% F.S.; Weight 1000±10 g |

| Copper Calorimeter Copper Plate | Imported Oxygen-Free superconducting copper |

| Data Acquisition System Sampling Rate | ≥ 20 samples/second |

| Environment | 15–35℃ |

| Fume Hood | Recommended internal dimensions ≥150×75×90 cm, including door height |

| Gas Source | Propane (Purity ≥95%, equipped with pressure reducing valve - cylinder & outlet pressure controlled) |

| Compressed Air | Customer-supplied |

| Cooling Water Source | Tap water (inlet & outlet) or optional chiller |

| Power supply | Single phase AC220V 50Hz |

| Dimension | 130×65×53cm (LXWXH) |

| Weight | Around 60kg |

1.Standard accessories

1pc:ASTM F2703 Dedicated Copper Calorimeter (for testing)

1pc:ASTM F2703 Dedicated Copper Calorimeter (for calibration)

1pc:Power Line

2.Optional accessories:

Optional:Schmidt-Boelter 100 kW/m² Standard Heat Flux Meter Calibration Kit (Meter + External Display)

Optional:Chiller Unit

Sample Conditioning: Cut specimens according to standard requirements and pre-treat them under specified conditions (e.g., drying at 105°C).

Specimen Mounting: Secure the specimen in a 45-degree fixture, ensuring the surface is flat and wrinkle-free.

Thread Ignition Cord: Install marked cotton cord at the designated position on the specimen and attach the timing weight or sensor.

Flame Adjustment: Ignite the butane gas and precisely adjust the flame height to 16mm using the scale.

Ignition Initiation: Press the start button; the ignition burner automatically moves toward the specimen and ignites it (typically retracting after 1 second).

Data Reading: When the sample burns to the marked line and melts the cotton thread, the timer automatically stops. Record the displayed spread time.

Timely Carbon Removal: After each test, promptly clean carbon deposits and combustion residues from the burner and sample holder to prevent gas line blockage.

Gas Line Sealing: Periodically inspect gas source connection hoses with soapy water to ensure no gas leaks.

Sensor Cleaning: Maintain cleanliness of the flame-detection device to prevent ash ingress causing timing failure.

Environmental Ventilation: Conduct tests within a fume hood. Activate exhaust systems post-test to remove hazardous fumes.

1. What is the minimum TPP rating for PPE?

For the purpose of measuring actual time to burn, the TPP rating is divided in half to determine the number of seconds until human tissue reaches the second-degree burn point. Thus, the NFPA minimum requirement of a TPP rating of 35 equates to 17 ½ seconds until second-degree burns occur in a flashover situation.

2.What is the thermal protective performance test?

The Thermal Protective Performance (TPP) Test Device was developed to measure the time elapsed for convective and radiant heat to penetrate through a protective composite fabric system - measuring the resulting damage to human skin.

3.What is the use of TPA on ships?

The Thermal Protective Aid (TPA) is an essential component of maritime safety equipment, designed to prevent hypothermia and protect survivors from harsh environmental conditions during emergencies at sea.

4.What does 5 5 5 mean to a firefighter?

It originated with the telegraph system used to dispatch fire alarms, where the code 5-5-5-5 signaled a death, usually of a firefighter or the mayor. The signal is a series of five bell strikes, repeated four times, with a pause between each set of five.

5.How hot is too hot for firefighters?

But how hot is too hot when you're confronted with a fire? The effects of heat stress begin to affect firefighters with even the slightest increase in body temperature. An increase to 99.5 degrees Fahrenheit, just 0.9 degrees higher than what is considered normal, will begin to impact one's hearing.

Recommended related products:

1、Thermal Radiation Performance Tester(RPP)

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com