It is applicable to detect broken needle and iron matters inmany industries such as garment, textile

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

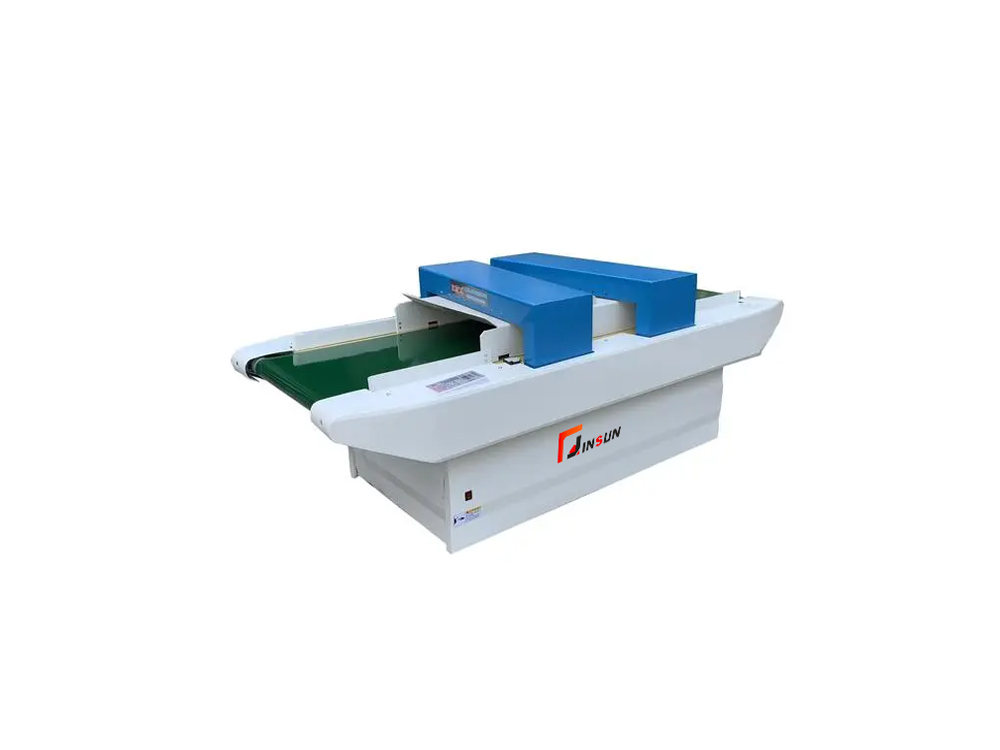

It is applicable to detect broken needle and iron matters inmany industries such as garment, textile, shoes and hats,home textiles, quilting etc.

Power voltage: AC220V 50Hz ±10%

Power: 9OW

Detection width: 600mm

Height passing the products: 80,110,130,150mm

Sensitivity: O-10 level adjustable

Detectability:0.8,1.0,1.2,1.5Fe iron ball have reaction

Conveyor belt rotation speed:30mz/min

External dimension: (Length x Width x Height)2400×1050×900 mm

Gross weight: 320kg

1、Configure with anti-static non-metal rubber conveyor belt.

2、Alarm modes are respectively sound and light to worksimultaneously, enable to help operators to find

3、Machine equipped with counting function, it is divided intogood product, bad product and summation.

4、Possess the detection of thick fabric and thin fabric, aswell as functions such as automatic return of detectedgoods and automatic counting etc.

5、The type of needle detector possesses the largest featureas:one-time detection obtains twice needle detectioneffects, and two detection heads display in form of “X”,increases 30% cutting surface based on magnetic fieldcutting of single head, largely upgrades detection quality.

6、The machine adopts special magnetic-sensing materialsand special technology to manufacture scientifically tomake particularly high detection accuracy, and scientificallysolves "common fault”as poor anti-interference existingin needle detector field currently.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com