Tests the wear resistance of glass surfaces by applying controlled abrasive forces and motion.

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

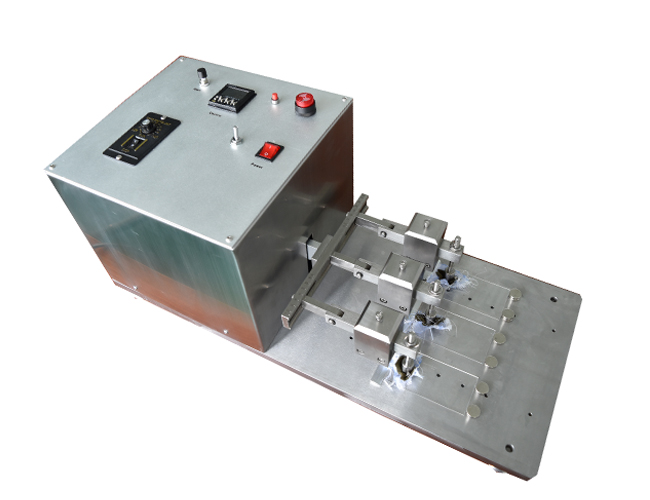

The Glass Scratch/Abrasion Tester is used to test the scratch and abrasion resistance of glass. This instrument uses a counter to set the number of rubbing cycles and a speed controller to adjust the operating speed of the rubbing head to meet the customer's actual testing needs. During the test, a 10mm*10mm rubbing head equipped with steel wool is used. Adjustable weights adjust the pressure load of the rubbing head to rub the glass. After the test, the sample is removed and its scratch and abrasion resistance is evaluated.

Automotive Glass: Assesses windshield durability against environmental wear.

Consumer Electronics: Tests smartphone screens, tablet covers, and display panels.

Architectural Glass: Validates window and facade materials for long-term performance.

Medical Devices: Ensures compliance with biocompatibility standards (e.g., ISO 10993-7).

ISO 10993-7: Biological Evaluation of Medical Devices – Ethylene Oxide Sterilization Residuals

USP (United States Pharmacopeia): Container Performance Testing

Ph. Eur. (European Pharmacopoeia): Glass Containers for Pharmaceutical Use

JP (Japanese Pharmacopoeia): Glass Container Testing Standards

GB/T 16886.7: Biological Evaluation of Medical Devices – Ethylene Oxide Sterilization Validation

Three Independent Workstations: Enables parallel testing of diverse glass types.

Adjustable Friction Head: 10mm × 10mm steel wool attachment with load regulation (0–10N).

Speed Governor: Controls reciprocating motion (50 ±5 mm stroke) up to 120 RPM.

Safety Interlocks: Prevents accidental start-up and overload damage.

Easy Sample Handling: Quick-release clamps for rapid sample exchange.

Digital Display: Monitors test parameters (load, speed, cycles) in real time.

| Parameter | Specification |

|---|---|

| Control Mode | Automatic (PLC) |

| Maximum Load | 10 N (Adjustable) |

| Speed Range | 0–120 RPM (Reciprocating) |

| Stroke Length | 50 ±5 mm |

| Workstations | 3 (Independent) |

| Friction Head Size | 10 mm × 10 mm (Steel Wool Attachment) |

| Power Supply | AC 220V ±10%, 50Hz |

| Dimensions (L×W×H) | 800 mm × 400 mm × 500 mm |

| Net Weight | 85 kg |

| Display | LED Touchscreen (Load/Speed/Cycle Control) |

Place the cut sample on the sample clamping platform and clamp it securely.

Fix the weights, ensuring full contact between the friction head and the sample, and tighten the device.

Turn on the machine and select the desired test mode (specified number of times or continuous operation). Then set the desired number of friction cycles and the desired operating speed.

Turn on the speed controller switch and press the start button; the equipment will begin operation.

After the test, record the surface friction of the sample and assign a relevant rating.

YouTube video introduction:https://www.youtube.com/watch?v=1efXDpuY9ZA

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com