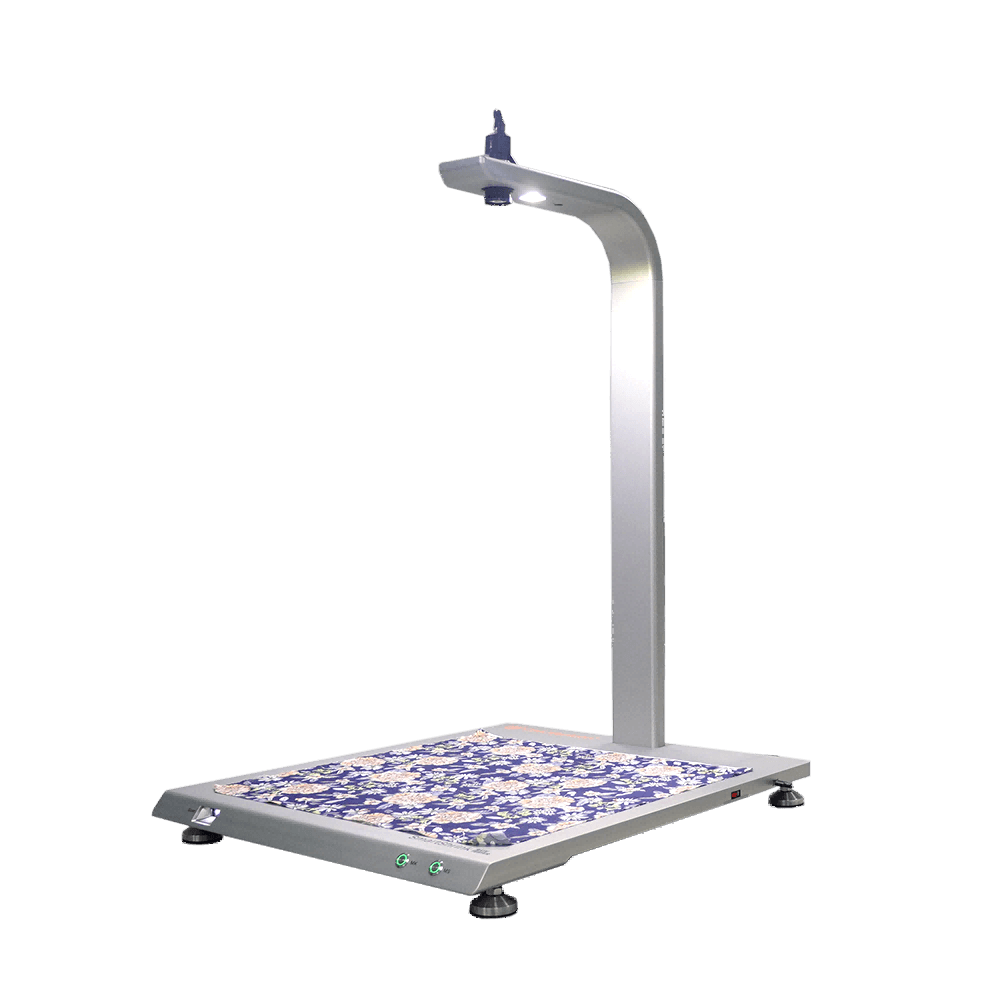

Equipment and procedures to measure woolen fabric dimensional change after cleaning.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Meet the standard:

AATCC 135

ISO 6330

ISO 5077

Product Introduction:

Woolen fabrics, due to the unique structure of wool fibers, can be prone to felting shrinkage when subjected to heat, moisture, and mechanical action, particularly in washing. Testing shrinkage allows manufacturers to predict how a fabric will behave after cleaning and to ensure consistent quality.

The testing process typically involves several steps utilizing specific equipment:

Sample Preparation and Marking: Fabric specimens of a standard size are cut. Fiducial marks (usually three marks in two perpendicular directions, parallel to the warp and weft of the fabric) are applied to the specimens using a template or marking guide and a suitable marking pen. The distance between these marks is precisely measured before treatment using a measuring scale or ruler.

Controlled Treatment: The marked specimens are subjected to a specified laundering procedure using a standardized laboratory washing machine and tumble dryer (as defined by standards like ISO 6330 or AATCC 135). The washing parameters (temperature, water level, agitation, detergent type and amount) and drying parameters are strictly controlled. Alternatively, specimens may be subjected to a standardized dry cleaning process.

Conditioning: After treatment and drying, the specimens are conditioned in a controlled temperature and humidity environment to allow them to reach moisture equilibrium before final measurement.

Final Measurement: The distances between the fiducial marks on the conditioned specimens are measured again using the same scale or ruler and template/frame to ensure the fabric lies flat without tension.

Calculation: The percentage of dimensional change (shrinkage or growth) in both the warp and weft directions is calculated based on the measurements before and after the treatment. Shrinkage is indicated by a decrease in dimension, while growth is indicated by an increase.

The "Tester" thus encompasses the controlled washing/drying equipment, the marking and measurement tools, and the adherence to standardized procedures.

The instrument is used in laboratories for:

Quality control of woolen fabrics and garments to ensure dimensional stability after cleaning.

Product development and material selection to identify fabrics with acceptable shrinkage characteristics.

Compliance testing with industry standards and retailer specifications.

Investigating consumer complaints related to fabric shrinkage.

Research into the shrinkage behavior of wool and the effectiveness of anti-shrink treatments.

Product Advantages:

Provides objective, quantitative measurement of fabric shrinkage or growth.

Essential for quality control and ensuring the performance of woolen textiles in use.

Helps predict how fabrics will behave after specified cleaning procedures.

Standard compliant test methods (ISO 6330. ISO 5077. AATCC 135) ensure comparable and reliable results.

Useful for material comparison and product development.

Supports compliance with industry standards and consumer expectations for dimensional stability.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com