Evaluates performance and intelligent functions of cleaning equipment.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Meet the standard:

IEC 62885-7

IEC 60335-2-72

IEC 63327

CSA 22.2 No. 336

ASTM D4488

ISO 8502-3

Scope of Application:

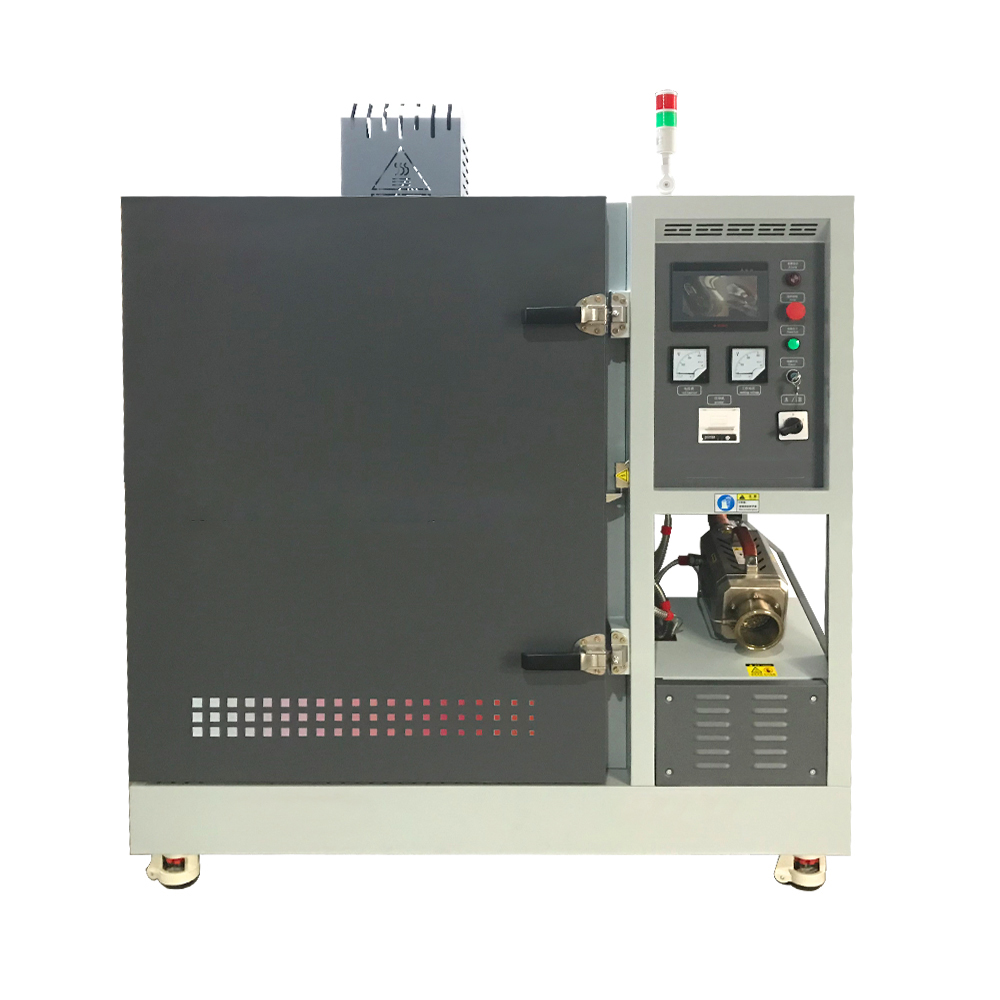

The purpose of an Intelligent Cleaning Equipment Tester is to provide a standardized and repeatable method for evaluating the capabilities of cleaning equipment, especially those incorporating advanced features like sensors, navigation systems, and automation. This involves simulating real-world cleaning tasks and environments under controlled laboratory conditions. Testing can encompass quantitative measurement of cleaning effectiveness on various surfaces and soil types, assessment of coverage area and cleaning speed, evaluation of battery life and power consumption, measurement of noise levels, and testing the functionality and accuracy of intelligent features such as navigation, mapping, obstacle detection and avoidance, and automatic docking and charging. The data collected is used for product development, quality control, performance benchmarking, and ensuring compliance with safety and performance standards.

The instrument is used by:

Manufacturers of intelligent cleaning equipment for R&D and quality assurance.

Testing laboratories for certification and performance verification.

Consumer organizations for product reviews and comparisons.

Developers of cleaning agents to evaluate their effectiveness when used with specific equipment.

Product Advantages:

Objective Performance Evaluation: Provides quantifiable data on cleaning effectiveness, coverage, speed, and other key performance indicators.

Standardized Test Environment: Allows for repeatable testing under controlled conditions, minimizing external variables.

Assessment of Intelligent Features: Enables systematic testing of navigation, mapping, and obstacle interaction capabilities.

Supports Product Development: Provides crucial data for optimizing cleaning algorithms, hardware design, and overall performance.

Facilitates Quality Control: Helps ensure manufactured units meet specified performance and functional requirements.

Performance Benchmarking: Allows for comparison of different equipment models or technologies.

Automated Data Collection: Can often automate the collection and analysis of test data, improving efficiency.

Product Features:

Standardized test surfaces: Modules or areas representing various flooring types (e.g., hard floor, carpet, tile) and potentially wall surfaces.

Standardized soil application system: Devices for applying specific types and quantities of artificial soil in a repeatable manner (e.g., dust, particles, liquids, stains).

Cleaning effectiveness measurement system: Instruments or methods for objectively measuring the amount of residual soil after cleaning (e.g., gravimetric analysis, photometers measuring reflectance, ATP meters for microbial cleanliness, visual grading scales).

Coverage and navigation tracking system: Sensors, cameras, or tracking software to monitor the path taken by the cleaning equipment, coverage area, and interaction with obstacles.

Standardized test environments with obstacles: Configurable layouts mimicking rooms with furniture, walls, edges, and potential hazards (e.g., stairs, cables) to test navigation and obstacle avoidance.

Measurement instruments for other performance parameters: Integrated or external devices for measuring noise levels, suction power (for vacuums), water/solution consumption, and power consumption/battery life.

Data acquisition and analysis system: Software for recording test parameters, collecting data from various sensors, analyzing performance metrics (e.g., cleaning efficiency percentage, coverage maps, error logs), and generating test reports.

Control system: For setting up test parameters, initiating test cycles, and potentially controlling aspects of the test environment.

Fixtures or docks: For initiating automated functions like docking and charging tests.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com