Steam generator for automotive thermal shock tests per OEM standards.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The 100-V2 Steam Generator is designed for automotive thermal shock testing, capable of generating precise steam conditions required by major OEM thermal shock specifications. It provides controllable steam flow and pressure for repeatable testing of automotive components under thermal stress.

(1) Automotive Thermal Shock Testing: Simulates rapid temperature changes on vehicle components using controlled steam injection.

(2) OEM Compliance Testing: Meets Ford, GM, and FCA thermal shock specifications for component validation.

(3) R&D and Quality Control: Evaluates thermal resistance and durability of automotive parts during design and production.

(4) Material and Component Verification: Supports verification of seals, coatings, and heat-sensitive parts under thermal stress.

(1) Ford FLTM BI 107-05 – Thermal shock testing method using steam.

(2) GMW15919 – General Motors thermal shock test standard.

(3) FCA LP-463PB-64-01 – FCA/Penske automotive thermal shock specification.

(4) ISO 20473 – Thermal shock testing methodology (related international standard).

(5) ASTM D1831 – Thermal shock testing of metallic and non-metallic components.

(1) Dedicated Steam Generator Unit: Ensures precise and repeatable steam output.

(2) Adjustable Gas/Electric Burner: Flexible control over heating and steam generation.

(3) Controlled Water Flow Rate: 2.7 ± 0.1 L/min for stable steam production.

(4) Controlled Steam Dynamic Pressure: 37.9 ± 1.9 kPa at the nozzle.

(5) Compatible High Temperature/Pressure Hoses: Designed for use with automotive thermal shock setups.

(6) Tubular Nozzle: Non-corrosive, inner diameter 12.5 ± 0.3 mm, length ≥100 mm.

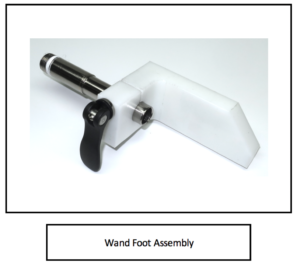

(7) Dynamic Head Clamp (STD-DHF-1): Measures discharge dynamic head pressure 37.9 ± 1.9 kPa, positioned 25 mm from nozzle using 4.7 mm bore tube.

(8) OEM Approved System Integration: Recognized by Ford, GM, and FCA for thermal shock testing.

| Parameter | Specification |

|---|---|

| Model | STD-100-V2 |

| Water Flow Rate | 2.7 ± 0.1 L/min |

| Steam Dynamic Pressure | 37.9 ± 1.9 kPa |

| Tubular Nozzle | Inner diameter 12.5 ± 0.3 mm, length ≥100 mm, non-corrosive material |

| Burner Type | Adjustable gas/electric |

| Hose Compatibility | High temperature/high pressure steam hoses |

| Dynamic Head Clamp | STD-DHF-1 |

| Measurement Distance | 25 mm from nozzle |

| Measurement Tube Bore | 4.7 mm |

| Power Supply | AC 220V / 50Hz (standard) |

| Operating Environment | Laboratory/Automotive test bench |

(1) Tubular nozzle (non-corrosive material)

(2) High-temperature, high-pressure steam hoses

(3) Dynamic Head Clamp (STD-DHF-1)

(4) Adjustable gas/electric burner

(5) Calibration and connection fittings

(1) Connect the 100-V2 steam generator to the test setup using compatible hoses.

(2) Install the tubular nozzle and position the dynamic head clamp 25 mm from the nozzle.

(3) Adjust burner to generate steam at controlled flow rate (2.7 ± 0.1 L/min).

(4) Verify nozzle steam dynamic pressure (37.9 ± 1.9 kPa) using STD-DHF-1.

(5) Conduct thermal shock tests according to OEM specifications (Ford FLTM BI 107-05, GMW15919, FCA LP-463PB-64-01).

(6) Record and analyze data for component validation and compliance verification.

(1) Regularly inspect hoses and nozzle for corrosion or blockage.

(2) Ensure burner is clean and free from debris to maintain steam consistency.

(3) Periodically calibrate dynamic head clamp (STD-DHF-1) for accurate pressure readings.

(4) Store generator and nozzle components in a dry environment when not in use.

(5) Use only deionized water to prevent mineral buildup in the steam generator.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com