Measures finished shoe bending resistance and cracking by repeated flexing per standards.

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

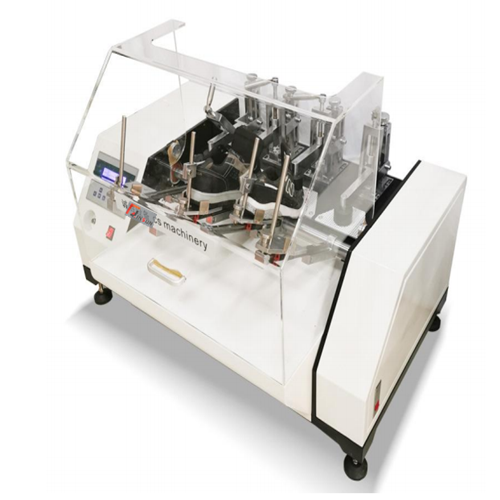

The finished shoe resistance zigzag tester drives the zigzag part of the finished shoe to zigzag repeatedly with the zigzag Angle matched by the shoe type and the fixed rate of the zigzag machine. After reaching the preset time or completing the specified zigzag number, the damage of the zigzag part of the finished shoe is observed and tested. To complete the number of twists and turns without damage or complete the specified number of twists and turns of the finished shoe to evaluate the zigzag resistance of the finished shoe.

The Finished Shoes Bending Tester/Shoe Bending Tester is a testing instrument independently produced by Shanghai Qianshi. It is used to test the bending resistance of shoes under dry and wet environmental conditions to evaluate whether the shoes meet quality standards.

(1)Testing sports shoes, casual shoes, work shoes, and safety footwear under dry and wet conditions.

(2)Evaluation of finished shoe durability in research and development for product quality assurance.

(3)Quality control in footwear manufacturing to ensure compliance with flexing and bending standards.

(4)Testing shoes with different sole materials such as rubber, EVA, PU, and leather.

(5)Assessment of zigzag resistance of shoes, particularly in critical stress areas like the toe or forefoot.

(6)Comparative testing of shoe construction methods, including cemented, stitched, or molded soles.

(7)Simulation of real-world walking conditions to evaluate long-term performance of footwear.

Satra TM92&77: Resistance of Footwear to Flexing

SATRA TM77: Flexing Machine - Water Penetration Test

Test sports shoes, casual shoes, work shoes and other finished shoes, after a long time, fixed frequency, fixed Angle of continuous bending, evaluate its folding performance or check its cracking degree.

Measures Finished Shoe Durability: Evaluates the flexing resistance of the entire shoe under simulated walking conditions, providing a realistic assessment of its durability.

Standard Compliant: Designed to meet relevant standards for finished footwear flexing resistance testing.

Multiple Testing Stations: Allows testing of two pairs of shoes simultaneously, increasing testing efficiency.

Controllable Test Parameters: Provides precise adjustment of bending angle and flexing speed to match different shoe types and test requirements.

Quantitative Evaluation: Results are based on the number of flexing cycles, either to a certain level of damage or to a specified total.

Suitable for Various Shoe Types: Applicable to a range of finished footwear, including sports, casual, and work shoes.

Includes Cycle Counter: The integrated counter provides an accurate record of the number of flexing cycles performed.

Precise Speed Control: The variable frequency motor ensures accurate and stable test speeds.

| Item | Specification |

|---|---|

| Testing Capacity | Two pairs of shoes can be tested simultaneously |

| Zigzag Angle | Adjustable from 5 to 90° |

| Zigzag Resistance Speed | 5 to 150cpm adjustable (with speed display) |

| Permissible Sample Length | 150 to 400mm |

| Volume | 1058378cm |

| Motor | Variable frequency motor |

| Counter | LCD, 0-9999.999 |

| Power Supply | AC220V, 10A |

1. Select a suitable pair of toe clamps from the five pairs provided by the shoe sole flexure tester/shoe bending tester to clamp the toes, thus holding the shoe on the machine. The heel is fixed to the bending rod.

2. The number of bends can be preset using a counter. Once the corresponding number of bends is reached, the machine will stop running, allowing for shoe inspection.

(1)Toe clamps (five pairs) for different shoe sizes

(2)Heel fixture rod for secure sample mounting

(1)Select the appropriate pair of toe clamps and secure the toes of the shoes to the machine.

(2)Fix the heel of the shoe onto the bending rod.

(3)Set the desired number of bending cycles on the counter.

(4)Start the test; the machine performs repeated flexing according to the set angle and speed.

(5)After reaching the preset cycle count, the machine stops automatically.

(6)Inspect the shoes for damage or degradation in the flexing zones.

(1)Keep the bending mechanism clean and free from debris or adhesive residue.

(2)Check and lubricate moving components periodically to maintain smooth operation.

(3)Inspect the toe clamps and heel fixtures for wear or damage before use.

(4)Ensure the variable frequency motor and counter are functioning correctly.

(5)Store the tester in a dry and stable environment to prevent corrosion and mechanical wear.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com