The instrument is suitable for testing the abrasion resistance of plastic, auto parts, rubber, leath

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

It is suitable for testing the wear resistance of plastics, auto parts, rubber, leather and textile, electroplating, free disassembly, paint, printing and other products.

It can be used to evaluate the wear-resisting property of the products, and can be used for the single or multiple scratches and color transference of the affordable products.

Dry grinding test and wet grinding test can be carried out. Suitable for testing any size or shape of the product, the abrasion test of the product with contour surface and polishing surface characteristics is ideal.

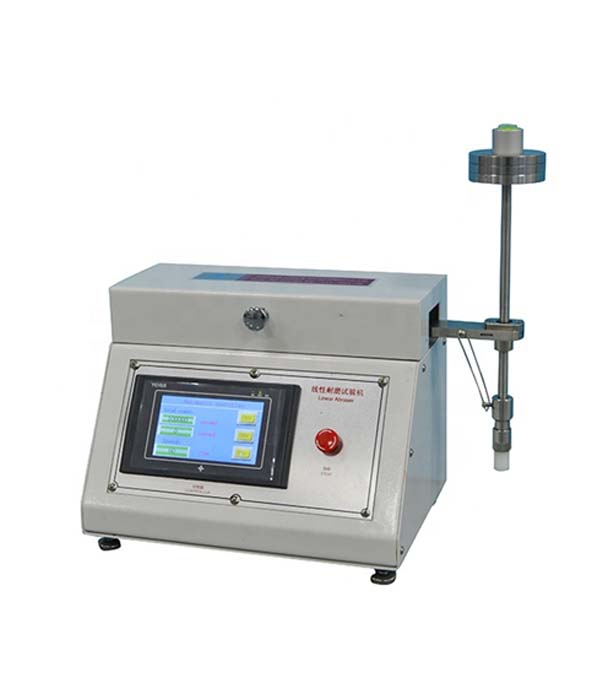

This linear abrasion tester features a metal arm protruding from the side at the top, and it is able to make reciprocating motion horizontally in a linear path. It allows you to manually adjust the stroke distance according to test requirements. There are 8 adjustable distances available, including 0.5”, 1”, 40 mm, 2”, 2.5”, 3” 3.5” and 4” .

A metal rod with two longitudinal guide grooves is provided. You need to insert the rod straight down and through the bore at the free end of the arm during the setup process. The auxiliary attachments holding the abrading medium corresponding to your testing are required to be secured at the bottom of the rod. The genuine pencil erasers of different models from Taber Industries as a commonly used medium are available to be provided with the machine if required.

5 disc weights of different masses (Default configurations: 50 g & 100 g & 3 x 250 g ) are permitted to be superimposed on top of the rod in a certain combination to exert an anticipated pressure on the specimen. The rod is not fixed, and it can move up and down freely with the change in the flatness of the contact surface between the abrading finger and the specimen when the contoured specimen is tested.

To evaluate the abrasion resistance, scratch resistance of products (single or multiple scratches) and the transitivity of color (Usually crocking resistance or rubbing fastness) and so on. And can do dry abrasion test, wet abrasion test.

ASTM D3884 , ASTM D1175 , ASTM D1044 , ASTM D4060 ,

TAPPI T476 , ISO 9352 , ISO 5470-1 ,

JIS K7204 , JIS A1453, JIS K6902 , JIS L1096 , JIS K6964 ,

DIN 52347 , DIN 53109 , DIN 53754 , DIN 53799

| Move distances | ''0.5'', ''1'', ''2'', ''3'' and ''4''; Special distance can be customized. |

| Adjustable RPM | 0-999,999 RPM (Revolutions Per Minute) |

| (Note: rubber grinding head may need to be replaced during this period). | |

| Test speed | 0-60 times/min, adjustable movement speed. |

| TABER standard speed: 2, 15, 25, 30, 40 and 60 return/min | |

| Standard load ranges | 350g~2,100g ( 250g , 3pcs, or customized) |

| Power supply | 220V 50HZ or customized |

| Machine size | 430*280*480 cm |

1. Parameters such as moving distance, rotating speed, rotation number and load can be set.

2. Various wear media and accessories can be selected.(the optional sample holder and other optional accessories shall be matched with the test of hanging, damage degree, alcohol resistance test, coin scratch resistance test, etc.)

3. Ensure the stability and accuracy of the test: generally, the grinding head is of the same size and shape as the rubber wipe head at the end of the pencil. It is made of high quality abrasion materials. It can ensure the stability of the test.

Abrasion Testing: This method involves the use of abrasive materials that are applied to the surface of the material and subjected to mechanical movement to cause wear. Parameters such as weight loss or depth of wear are then measured to evaluate the material’s resistance to wear.

The Taber Abrasion Test uses a rotating platform with attached abrasive wheels or disks that apply a specific load to the surface of the material or product under test. The material is subjected to rotational and sliding movements and the resulting wear – weight loss and depth of damage – is measured. The Taber test is a widely used method for evaluating the abrasion resistance of materials. These testers are also called Taber abraser or Taber abrader.

Scratch Testing evaluates the resistance of a material to scratches and surface damage. Various test methods can be used, such as using a stylus or indenter with known hardness to apply a controlled force to the surface of the material. Scratch depth, weight loss, and visual damage assessment are used to evaluate the scratch resistance of a material.

A special mention should be made of The Linear Taber Abrasion Test.

The Linear Taber Test: Both Abrasion and Scratch Resistance

The Linear Taber Abrasion Test can be considered more versatile compared to the standard Taber Abrasion Test in terms of evaluating both abrasion resistance and scratch resistance. While the standard Taber Abrasion Test primarily focuses on evaluating the material’s resistance to rotational and sliding abrasion, the linear variant incorporates linear or back-and-forth motion, which allows for a wider range of wear and damage to be assessed.

By utilizing linear motion, the Linear Taber Abrasion Test can simulate various types of wear and friction that materials may encounter in real-world applications, including both abrasive forces and scratches. This makes it suitable for evaluating material performance in situations where linear wear or scratching is an issue.

The test results, weight loss, scratch depth and/or colour fastness are evaluated against each other or against standard samples. In this way, the quality of the products is maintained at the proper level during routine quality control, or improved during tests aimed at selecting a more suitable material for the application.

It is important to note that while the Taber linear abrasion test provides valuable information about abrasion and scratch resistance, specialized scratch test methods that specifically focus on scratch phenomena can provide more detailed and accurate results for scratch resistance assessment. Nevertheless, the versatility of the Linear Taber abrasion test makes it a valuable tool for evaluating the durability and wear resistance of materials in a variety of applications.

During operation, first cut the material to be tested into samples of specified size, fix the samples on the fixture of the testing machine, then place the wear head on the surface of the sample, and start the linear wear test by adjusting parameters such as load and number of round trips. During the test, the surface of the sample rubs against the wear head, and the friction force and the number of reciprocations gradually increase until the set stop conditions are reached, such as test time, wear amount or wear depth, etc.

The steps to operate the linear abrasion testing machine are as follows:

Prepare the sample: Cut the material to be tested into a sample according to the standard specification.

Install the sample: Fix the sample on the fixture of the testing machine.

Set test parameters: set test parameters such as load, number of round trips, and stop conditions.

Start the test: Start the testing machine and start the test.

End the test: When the test reaches the set stop condition, stop the testing machine and take out the sample.

Check the sample: check the wear on the surface of the sample, record the test data and analyze it.

What Are the Test Functions of the Taber Linear Abraser?

The Taber linear abraser is a multipurpose testing apparatus, and it can fulfill various test projects by replacing different test attachments and abradants.

Generally speaking, it is mainly used to determine the following properties of materials:

Abrasion resistance

Color fastness to rubbing of textiles or printing materials

Scrape or mar resistance

Film hardness, etc.

What Shapes of Samples Can This Linear Abraser Accept?

Thanks to a pair of special clamping devices and a universal specimen mounting table, Samples of almost any shape can be mounted and fixed. In addition, the rubbing head can move up and down with the test contact surface of the sample when doing lateral linear motion. These features allow this linear abraser to accept regular-shaped products like cuboids and cubes and irregular-shaped products like contoured items.

What Is the Test Procedure of Conducting the Abrasion Test with the Taber Linear Abraser?

The most commonly used test attachment for the abrasion test is the collet, which is a standard acceesary from AmadeTech. It should be attached to the bottom of the vertical shaft and hold a corresponding cyclindrical abradant from Taber industries tightly by a threaded mechanism. The specimen with flat or contoured test surface is requred to be pressed and secured to the specimen mounting table next to the machine by means of a pair of securing plates and screws attached, ensuring that the moving path of the rubbing finger is across the intended test area of the specimen.

Pull the lid of the machine up and manually choose a specified stroke length of the horizontal arm if required. Switch on the machine and rotate the emergency stop button clockwise to allow the device to be ready. Tap the corresponding virtual buttons on the touch screen to set the number of test runs and test speed in accordance with the related requirements.

Tap the “Test” button to initiate the test permitting the rubbing action to happen over the specimen with the back-and-forth movement of the rubbing finger. When predetermined number of test cycles is achieved, the specimen is inspected for change or damage.

How to Assess the Test Results when Tested with the Taber Linear Abraser?

As we all know, The Taber Linear Abraser is a universal testing instrument that is compatible with various testing items and testing standards. Different test methods have different judging methods. It is impossible for us to list all evaluation methods here. Based on their commonality, the core evaluation methods mainly include the following two types:

The first method is subjecting the sample to testing for a predetermined number of test cycles and then examining it for changes in appearance or properties, such as color, gloss, hardness, scratch, etc. Or you can compare the abraded sample with a recognized standard template to obtain the test results.

The second method is weighing the mass of the sample before and after the test, then subtracting the mass of the sample after the test from the mass of the sample before the test to get the mass lost during the test to determine its wear resistance. Generally speaking, under the same test conditions for different samples, less mass loss means more wear-resistant, and greater mass loss means less wear-resistant.

In general, the evaluation criteria of this taber linear abraser and taber rotary platform abraser have certain similarities. In actual operation, please evaluate the test results strictly according to the requirements of the standards you follow.

What Standard Test Attachments Does AmadeTech supply?

Metal collet: used for holding the Wearaser abradant when conducting abrasion testing.

Pencil fixture: used as an aid to determine the film hardness by pencil test.

Rubbing finger & cloth: used to determine the dissolution resistance of coatings or printing pigments on substrates to various solvents such as alcohol by rubbing.

What Models of the Original Small Eraser Abradants From Taber Are Available from AmadeTech?

Available models : CS-5, CS-8, CS-10, CS-10F, CS-17, H-10, H-18, H-22, H-38, CS-2, H1 Felt, Eraser 12397

How Much Force Can the Device Exert on the Sample During the Test?

5 pcs of disc-shaped weights are included in the standard configurations, including 1 pc of 50 g, 1 pc of 100 g and 3 pcs of 250 g. The metal rod’s mass is 350 g.

The weight can be stacked on the top of the rod. You are available to combine different weights according to different needs to get the desired pressure on the sample, such as 400 g, 500g, 1000 g, etc.

How to Change the stroke length of the Linear Abraser?

Open the cover on the top of the machine, and you will see that the end of the horizontal arm in the machine is connected by a transmission rod to the power swivel. There are multiple screw holes on the swivel. Each screw hole represents a unique stroke length of the horizontal arm. On the inner side of the cover, there is an instruction diagram on which the corresponding stroke of each hole is marked one by one. You just need to find the hole corresponding to the stroke you want, and then manually remove the screw and screw it into the desired hole to complete the change process. Remember to put the cover back after installation. Otherwise, the machine will not work.

What’s the Advantage of the Taber Linear Abraser Over the Taber Rotary Platform Abrader?

Due to the unique structural characteristics and testing mechanism of the Linear abrader, compared with the Taber rotary platform abrader requiring a specified size of a disc-shaped sample with a hole in the middle, it has almost no special requirements for the shape and size of the sample. It results in a greater variety of specimens that the machine can accept.

Compared with the fixed test accessories of the Taber rotary platform abrader, the Taber linear abrader can be flexibly matched with many different accessories to complete different tests, such as wear-resistance test, scratch resistance test, color fastness test, and so on.

In short, compared with the rotary platform abrader, the linear abrader has a higher degree of compatibility and a wider range of test applications.

Can I customize Some Features to Satisfy My Testing Conditions?

Of course.

You can advise us of your special requirements if the standard machine can’t suit your testing requirements. We will make corresponding assessments and propose feasible solutions to provide you with customized services.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com