Measures finished shoe dynamic waterproofness by bending in water per standards.

WhatsApp : +86 15601902607

Email : info@qinsun-lab.com

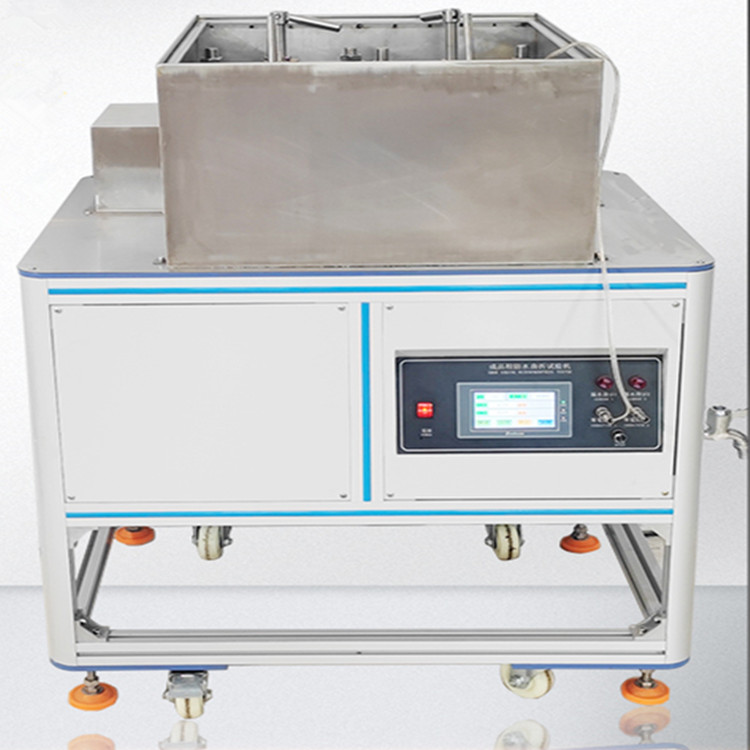

The Footwear Dynamic Waterproof Tester is designed to evaluate the waterproof performance of finished shoes under dynamic, flexing conditions. By simulating walking and repeated bending in a controlled water environment, the instrument measures either the number of cycles until water penetration occurs or the area of water ingress after a set number of cycles. This allows for a realistic assessment of footwear permeability and waterproof resistance.

(1)Testing finished shoes for dynamic waterproof performance under walking simulation.

(2)Evaluation of outdoor footwear, sports shoes, hiking shoes, and casual shoes.

(3)Assessment of rubber boots, insulated winter footwear, and protective work shoes.

(4)Quality control in footwear manufacturing for water-resistant shoes.

(5)Research and development of new shoe materials with improved waterproofing.

(6)Verification of compliance with national and industry waterproof standards.

(7)Inspection of finished shoe prototypes for functional performance.

(1)GB/T 16641 — Testing Method for Waterproof Performance of Footwear under Dynamic Conditions

(2)SATRA TM77 — Flexing Machine – Water Penetration Test for Footwear

(3)EN ISO 20344 — Personal Protective Equipment — Test Methods for Footwear

(4)ASTM F1670 — Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Synthetic Blood (adapted methodology for water penetration)

(5)ASTM F2912 — Standard Test Method for Water Penetration of Footwear

(6)ISO 20344:2011 — Footwear — Test Methods for Evaluating Performance of Finished Footwear

(7)DIN 33502 — Testing of Footwear for Waterproofing Properties

(8)BS 7979 — Specification for Water Penetration Resistance of Footwear

(9)AATCC TM 127 — Water Resistance: Hydrostatic Pressure Test (adapted for footwear materials)

(1)Simulates walking flex with adjustable bending angles and speeds.

(2)Measures dynamic waterproof performance quantitatively, based on cycles to water penetration or penetration area.

(3)Multiple testing stations to allow simultaneous testing of a pair of shoes.

(4)Integrated counter tracks the number of flexing cycles accurately.

(5)Adjustable zigzag angle (5–60°) to match different shoe types.

(6)Variable zigzag speed (5–150 cycles/min) for diverse testing requirements.

(7)Durable construction suitable for wet testing environments.

(8)Touch screen interface for cycle counting and parameter setting.

(9)Water tank with controlled depth and dyed water for clear visualization of water penetration.

(10)Compatible with various types of finished footwear, including sports, casual, and protective shoes.

| Item | Specification |

|---|---|

| Zigzag Angle | 5–60° adjustable |

| Zigzag Speed | 5–150 times/min adjustable |

| Test Quantity | 2 finished shoes simultaneously |

| Counter | 0–999,999 (touch screen display, arbitrarily set) |

| Volume | 73 × 82 × 108 cm |

| Power Supply | AC220V, 10A |

(1)Water tank with dyed water.

(2)Sample shoe holders/clamps.

(3)Touch screen controller.

(4)User manual and calibration certificate.

(1)Install the finished shoes on the shoe holders/clamps in the water tank.

(2)Set the desired zigzag angle and flexing speed on the touch screen interface.

(3)Fill the tank with water to the required depth and add dye for penetration visualization.

(4)Start the test, allowing the zigzag mechanism to flex the shoes repeatedly.

(5)Monitor the shoes for water ingress; the system records the number of cycles until penetration or measures the penetration area after a preset number of cycles.

(6)After completion, remove the shoes and analyze waterproof performance according to the standard.

(1)Clean the water tank and shoe holders after each test to prevent residue buildup.

(2)Regularly inspect the zigzag mechanism and clamps for wear or misalignment.

(3)Check the touch screen and counter system for proper function.

(4)Drain and replace water regularly to maintain testing consistency.

(5)Store the equipment in a dry environment when not in use to prevent corrosion.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com