Standardized abrasive blocks (rubber/polymer) used in testers to simulate wear from rubbing or erasi

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Taber Grinding Wheels are standardized circular abrasive wheels specifically designed for use with the Taber Abraser instrument. These wheels, typically measuring about 2 inches (approximately 51 mm) in diameter, are made from various abrasive materials (such as resilient or vitrified binders with aluminum oxide or silicon carbide grit) to suit different test applications and material types. Two wheels are mounted on parallel spindles, which rotate the wheels against the surface of a flat test specimen placed on a rotating turntable. The wheels are angled slightly relative to the specimen's surface, creating a unique crisscross abrasion pattern from the center outwards. Different types and grades of wheels (e.g., CS-10. H-18) are used to simulate various wear conditions according to specific testing standards. They are consumables, and their performance changes with use, so they are typically refaced before each test and replaced after a specified number of cycles.

Standardized abrasive wheels for Taber Abraser, simulating wear on flat surfaces.

Grinding wheel heads, in the context of material testing, typically refer to the abrasive elements or assemblies used to perform grinding or abrasive wear tests on a specimen surface. While this can specifically mean the spindle and holder assembly on a Taber Abraser arm, it more broadly describes any standardized abrasive wheel or element designed to be mounted on a testing machine to impart grinding or abrasive action. These heads come in various forms and abrasive types (like bonded abrasives, coated abrasives) and are used in different abrasion testers to apply controlled grinding or abrasive wear under specified load and motion, evaluating the material's resistance to this type of degradation.

Abrasive elements or assemblies used to impart grinding or abrasive wear on test specimens.

Abrasive belts are continuous loops of flexible material (such as cloth or paper) coated with abrasive particles (grit). In material testing, abrasive belts are used in linear abrasion testers, such as the Taber Linear Abraser or similar reciprocating testers. The test specimen is typically secured on a flat bed, and the abrasive belt is mounted on a system of rollers above the specimen. The belt moves linearly back and forth across the specimen surface under a controlled downward force. The abrasive belt provides a consistent abrasive surface that simulates rubbing wear or linear scratching. Different grit sizes and types of abrasive belts are available to replicate various abrasive conditions, and the belts are replaced after a defined test area or duration to ensure consistent abrasion.

Continuous loops of abrasive material used in linear abrasion testers for simulating rubbing wear.

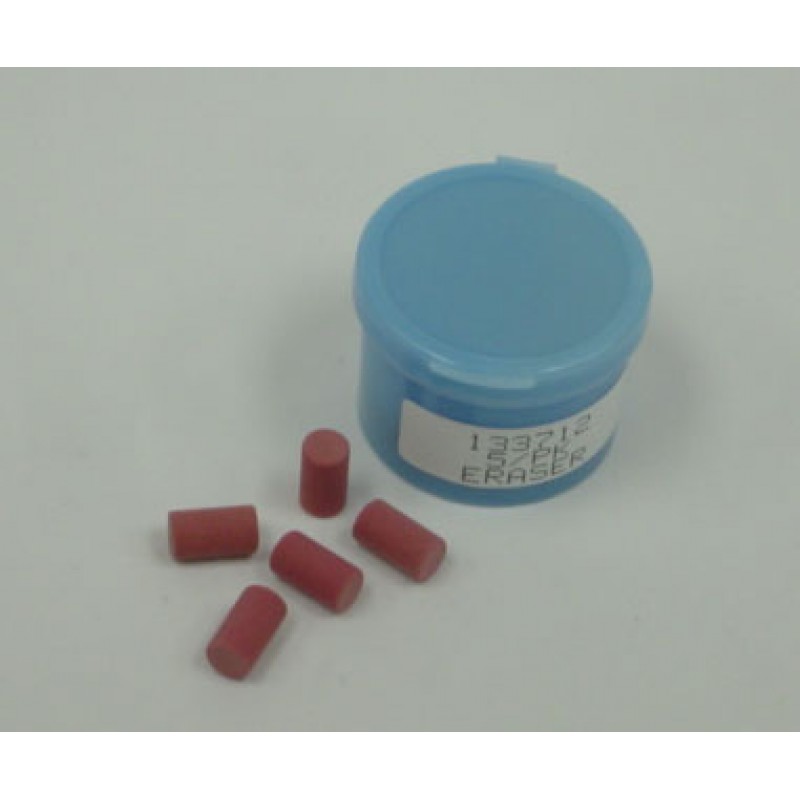

In material testing, erasers refer to standardized blocks made of rubber or a similar polymeric material that are used as an abrasive medium in specific types of abrasion or rub tests. Erasers are typically mounted in a testing machine that moves the eraser across the surface of a test specimen (such as a coated panel or printed material) under a controlled force and for a specified number of strokes. This test method simulates the type of wear or damage that can occur from rubbing with a rubbery material, such as accidental marks being erased or other forms of contact abrasion. Standardized erasers ensure consistent abrasive properties for repeatable test results, and the surface is evaluated for wear, removal of coating/ink, or other damage after the test.

DIN-53754/53799/53109. TAPPI-T476. ASTM-D3884. ISO5470-1.

| Grinding wheel/molding | Material/grinding characteristics | type | Element | Source |

| CS10/soft | Rubber and abrasive particles/soft | elasticity | Rubber,abrasive | Stocking |

| CS10F/soft | Rubber and abrasive particles/very gentle | elasticity | Rubber,abrasive | Reserve |

| CS17/soft | Rubber and abrasive/rough | elasticity | Rubber,abrasive | Stocking |

| Hard | Vitrified material/rough | Inelastic | ceramics | Reserve |

| H18/Hard | Vitrified material/medium roughness | Inelastic | ceramics | Reserve |

| H22/Hard | Vitrified material/medium roughness | Inelastic | ceramics | Reserve |

| H38/Hard | Vitrified material/medium roughness | Inelastic | ceramics | Reserve |

| CSO , S32 | Vitrified material/medium roughness | elasticity | Non-abrasive rubber | Reserve |

| S42 , S33 | Sandpaper belt/medium | elasticity | Sandpaper strips | Reserve |

| CS5/soft | Wool felt/no wear | elasticity | wool blanket | Reserve |

| S35/Hard | Tungsten carbide/cutting or chipping | Inelastic | Tungsten carbide | Reserve |

| S39/-- | leather/GritFeeder | leather | Reserve | |

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com