IntroductionThermal Manikin environment test simulation manikin exchange heat from the external envi

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The thermal manikin simulates real physiological heat exchange with the environment. By combining monitoring results with software analysis, it evaluates thermal comfort through protective clothing. It measures heat balance, analyzes environmental impact on comfort, and guides fabric/clothing development for special conditions. Using data-driven perception conclusions, it reduces errors from personal differences.

Comfort-oriented thermal human body models have wide applications in various fields, including but not limited to:

Architectural Design: Used to assess the thermal comfort of building interiors and optimize the design of ventilation and air conditioning systems.

Automotive Engineering: Used to assess the thermal comfort of passenger compartments and optimize the design of vehicle air conditioning and ventilation systems.

HVAC System Design: Used to assess and optimize the thermal comfort of buildings and indoor environments, improving energy efficiency.

Environmental Control: Used to predict and control thermal comfort under asymmetric thermal environments, providing personalized thermal demand regulation solutions.

These applications demonstrate the importance of comfort-oriented thermal human body models in improving human comfort and optimizing environmental control.

ISO 15831:2004: Clothing - Physiological effects - Measurement of thermal insulation by means of a thermal manikin

ASTM F1291: Standard Test Method for Measuring the Thermal Insulation of Clothing Using a Heated Manikin

ASTM F2370: Standard Test Method for Measuring the Evaporative Resistance of Clothing Using a Sweating Manikin

ISO 7730:2005: Ergonomics of the thermal environment - Analytical determination and interpretation of thermal comfort using calculation of the PMV and PPD indices and local thermal comfort criteria

1. Purple dolphin model with good thermal conductivity.

2. Dark treatment with the same skin radiation value as human’s . Perfect simulation of human skin;

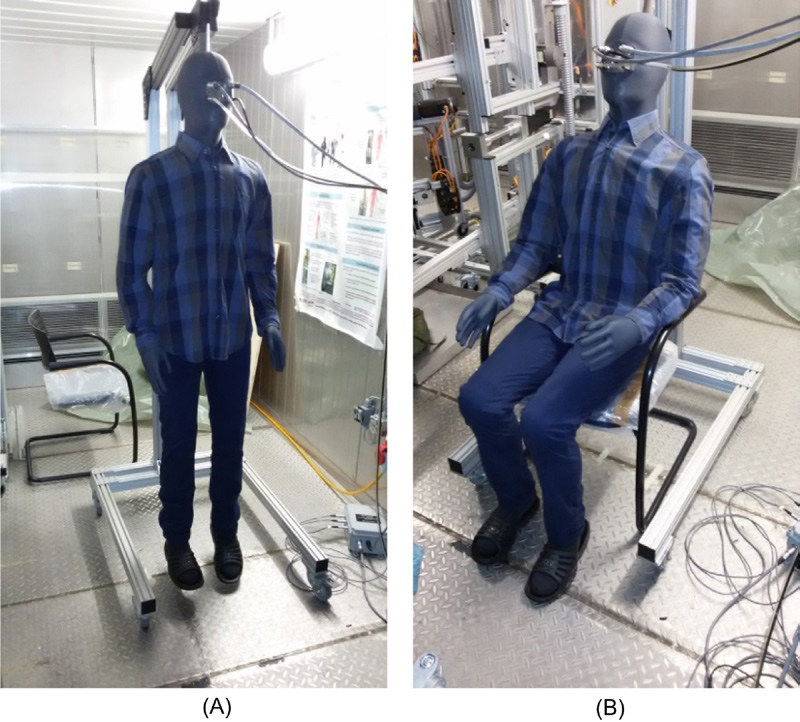

3.The modular manikin structure, easy to dismantle. Achieving the scene assembly measurement in the narrow space.

4. 11 independent control heating sections with high precision.

5. Heat insulation capacity in each independent heating section. Achieve special test requirements of the human body temperature difference. And the temperature difference up to 3 ℃ in the adjacent section. Easy to disassemble and install due to the 6 detachable joints.

6. Head cable drawing-off way is easy for clothing wear off.

7. 11 internal temperature monitoring segments, 11 external temperature monitoring segments, 11 power output segments, 4 ambient temperature monitoring segments, 2 environmental humidity monitoring segments.

8. PID algorithm combined with fuzzy algorithm to ensure good control accuracy.

9. Four kinds of work modes with automatic conversion and data record function: Constant temperature test, variable temperature test, constant power test, variable power test.

10. The analysis software provides the results of thermal resistance and CLO value.

Built-in thermal comfort evaluation model and the EQT evaluation model, which can analyze the thermal comfort feeling of the human body in the closed environment and the non-uniform thermal environment. And the thermal comfort value is quantifiable.

11. Anti-leakage safety protection device with the function of overrun alarm and overheating automatic power off.

| Parameter | Description |

|---|---|

| Dimensions | Adult male: 178.5cm height, 90.8cm chest, 73.2cm waist, 99cm hip; Child: 10yo/8yo with 16 sweating zones |

| Weight | 35 kg (adult male) |

| Temperature Range | -40°C to +50°C (with cold option), accuracy ±0.1°C |

| Humidity Range | 0-100% RH, accuracy ±3% |

| Sweating System | 0-1000 ml/hr/m² sweating rate, 16 independent zones |

| Heating/Cooling | Max 1000 W/m² heating, 350 W/m² cooling |

| Sensors | Thermal sensors for heat flux, pressure sensors for gas flow |

| Control Software | Pre-programmed software for experiment control, data analysis, and report generation |

| Data Acquisition | Real-time data collection with processing units and cables |

| Standards Compliance | ASTM F1291. ISO 15831. EN 342. etc. |

| Mobility | Adjustable posture (standing, walking, sitting, lying), detachable waist |

| Power Supply | Rechargeable batteries, 208-265 VAC power input |

| Additional Features | Thermal signature simulation, voice box for training, uniform weight distribution |

● Detachable comfortable thermal manikin, 1 set

● Manikin control system, 1 set

● System software, 1set

● Movable auxiliary hanger, 1 set

The operation method for comfort-type thermodynamic human models (such as dummies used for thermal comfort testing) covers experimental preparation, equipment connection, software settings, experimental execution, and post-experiment procedures. The following is a detailed description:

Experimental Preparation

Environmental Settings: Run the artificial climate chamber, set the required temperature and humidity conditions, and wait for the environment to stabilize. This is fundamental to ensuring the accuracy of the experimental results.

Dummy Preparation: Dress the dummy in the experimental sample (e.g., clothing) according to the experimental requirements. Ensure the dummy's joints are securely connected, especially if the experiment involves a walking system; check that the connecting rods for the walking system at the hands and feet are securely connected.

Water Bucket Preparation (if wet resistance or comfort testing is involved): Carry the white bucket to the deionized water room and fill it with water, ensuring the deionized water level is sufficient (more than 1/4 full).

Equipment Connection and Startup

Power Connection: Turn on the power strip and then start the DELL computer.

Data Cable Connection: Plug the gray data cable into the USB port of the DELL computer, ensuring smooth data transmission.

Equipment Switch: Turn on the power switch (usually located on the right side of the power supply box; I indicates the on position). If the experiment involves a water tank (such as for moisture resistance or comfort testing), the water tank switch must be turned on (usually located on the left side of the tank; "I" indicates the on state).

Software Setup and Startup

Software Startup: Open the ThermDac software (or other relevant software) on your computer desktop. Wait for the green COMM light on the software to illuminate, indicating normal operation.

Experiment Type Selection: Select the appropriate experiment type on the software toolbar according to the experimental requirements, such as thermal resistance test (SUDA-DRY TEST), moisture resistance test (SUDA-WET TEST), or comfort test.

Parameter Settings:

For moisture resistance and comfort tests, you may need to input the amount of sweat produced by various parts of the dummy or other relevant parameters.

For comfort tests, you may need to create a new tool, Model Control, and set the dummy's metabolic rate (ActLvl/MET) or walking speed (ActType), etc.

Experiment Execution

Start the Test: Click the "Start test" button in the lower right corner of the screen to begin the experiment. Save the file (it is recommended to create your own folder on the desktop so that you can copy the data after the experiment), and then click "Save". Data Recording: Wait for the experiment to end automatically (the message "Test completed" will appear), or collect data 30 minutes after the experimental conditions have stabilized according to standards. Manually end the experiment and save the data.

End Procedures:

Software Shutdown: First, close the ThermDac software (or other relevant software).

Equipment Shutdown: Turn off the computer, power supply box, and water tank switches (if applicable).

Power Shutdown: Finally, turn off the power strip and store the computer in a cabinet, locking it securely.

Follow-up Processing (e.g., for moisture resistance or comfort testing): After the experiment, a thermal resistance test may be necessary to dry the water inside the dummy to prevent damage to the equipment. Simultaneously, export and analyze the experimental data.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com