Measures safety helmet electrical insulation performance per standards.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

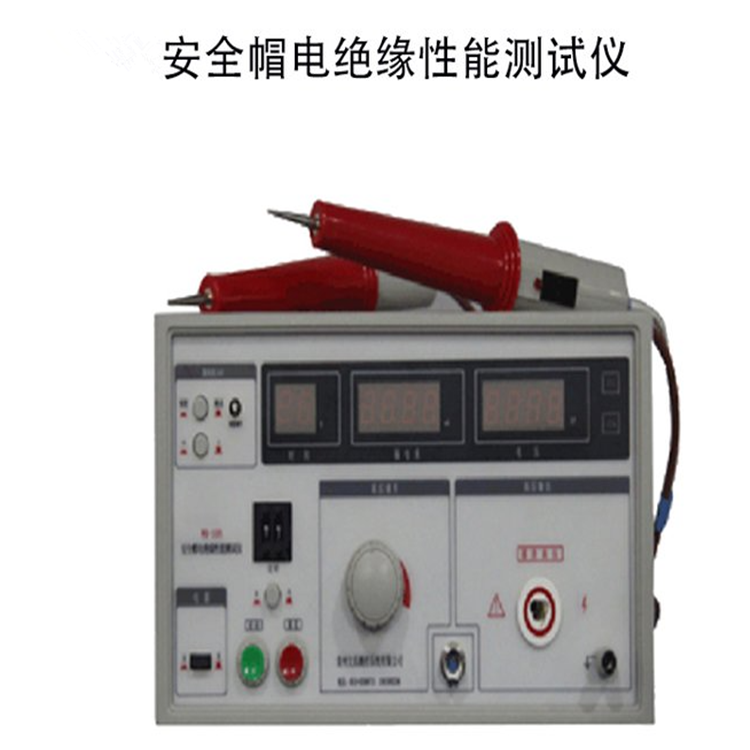

The Safety Helmet Electrical Insulation Tester is designed to assess the electrical insulation performance of safety helmets. It offers a high degree of automation, precise measurement, and ease of operation, making it suitable for helmet manufacturers, quality inspection laboratories, and safety testing facilities. The device ensures that helmets provide effective protection against electrical hazards.

The tester is widely used for:

(1) Safety Helmet Manufacturers: Verifying insulation performance during production to ensure compliance with safety standards.

(2) Quality Inspection Laboratories: Conducting routine testing for certification or quality control purposes.

(3) Research and Development: Assessing new helmet designs and materials for electrical safety performance.

Specific products tested include: industrial safety helmets, construction helmets, electrical hazard helmets, mining helmets, and high-voltage protective headgear.

The instrument complies with the following national and international standards:

(1) GB/T 2812-2006 – Safety helmet test method

(2) GB/T 2811-2007 – Safety helmet specifications

(1) Critical Safety Measurement: Quantifies electrical insulation performance to ensure wearer protection.

(2) High Automation: Automated voltage application and measurement for consistent, efficient testing.

(3) Objective Readouts: LED digital display provides accurate current and voltage readings.

(4) Plastic Sink System: Eliminates conductivity issues from metal sinks, ensuring precise results.

(5) Configurable Test Head: Adjustable electrodes to accommodate different helmet shapes and sizes.

(6) High-Voltage Control: Voltage can be increased up to 1200V ±25V within 1 minute and maintained for 15 seconds.

(7) Safety Design: Operator protection included during high-voltage testing.

| Parameter | Specification |

|---|---|

| Current Measurement Error | ±1% |

| Voltage Measurement Error | ±1% |

| Timer Error | ±1% |

| Probe Diameter | 4 mm, hemispherical top |

| Voltage Application | Increase to 1200V ±25V within 1 min, maintain for 15 s |

| Voltage Regulator Range | Up to 1500 V |

| Display | LED digital display for current and voltage |

| Test Medium | Plastic sink or water bath system |

| Automation | High degree of automation for test procedure |

(1) Electrical insulation test head – configurable according to customer requirements

(2) Power cable – 1 set

(3) User manual – 1 copy

(1) Place the safety helmet in the plastic sink or water bath system.

(2) Attach the test electrodes to the helmet according to the specified configuration.

(3) Activate the test sequence: gradually increase voltage to 1200V ±25V within 1 minute.

(4) Maintain voltage for 15 seconds while monitoring current and voltage readings.

(5) Record the measurements and verify that the helmet meets insulation requirements.

(6) Repeat for multiple helmets if necessary.

(1) Keep the plastic sink clean and free from contaminants.

(2) Inspect electrodes for wear or damage before each test.

(3) Ensure the LED display and electrical connections are functioning properly.

(4) Calibrate the voltage and current measurement system periodically.

(5) Store the tester in a dry, dust-free environment to ensure consistent performance.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com