Prepares safety helmets with UV irradiation before testing per standards.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

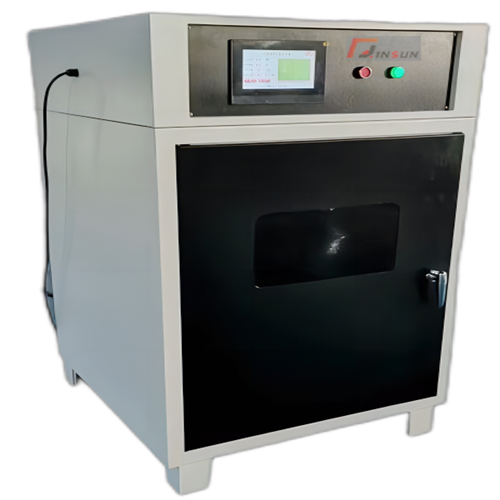

The Helmet UV Pretreatment Box is designed to simulate ultraviolet (UV) exposure on safety helmets, replicating natural sunlight aging effects to evaluate long-term durability and safety performance. It provides a controlled and standardized environment for UV irradiation, ensuring that helmet materials undergo consistent preconditioning before subsequent testing. The equipment is widely used in helmet manufacturing quality control, safety compliance verification, and research laboratories.

This tester has a broad range of applications in both laboratory testing and industrial quality assurance, including:

(1) Helmet Manufacturing: Pretreatment of industrial safety helmets, mining helmets, construction helmets, high-voltage insulating helmets, firefighting helmets, and arc flash helmets to simulate sunlight exposure before durability and performance tests.

(2) Material Research & Development: Testing engineering plastics, thermoplastics, and polymer composites used in helmet shells, visors, and internal supports for UV resistance and long-term stability.

(3) Laboratory Testing: Used in occupational safety and health labs, third-party testing institutions, and product certification labs to ensure compliance with national and international UV exposure standards.

(4) Special Applications: Pretreatment of sports helmets, cycling helmets, climbing helmets, or protective headgear in industries where UV exposure may affect material properties.

(5) Durability & Aging Studies: Enables simulation of long-term sunlight exposure to evaluate color stability, mechanical properties, and material degradation.

Specific products tested include:

Construction safety helmets

Firefighting helmets

High-voltage insulating helmets

Mining helmets

Engineering plastic helmet shells and visors

Arc flash protective helmets

The instrument meets both national and international standards, including:

(1) GB/T 2812-2006 – Safety helmet test method (China)

(2) GB/T 2811-2019 – Safety helmet (China)

(3) EN 397:2012+A1:2012 – Industrial safety helmets (Europe)

(4) EN 50365:2002 – Electrical insulating helmets for low-voltage installations (Europe)

(5) ANSI/ISEA Z89.1-2014 – Industrial head protection (USA)

(6) CSA Z94.1-15 – Industrial protective headwear (Canada)

(7) ISO 24450:2005 – Helmets for high-voltage electrical work (International)

(8) ASTM D4329-20 – Standard practice for exposure of plastics to UV and water (International)

(9) AATCC TM16 – Colorfastness to light (textiles and polymer surfaces)

(10) JIS T 8114 – Testing of helmets (Japan)

(11) BS EN 12470 – Helmets for head protection (UK)

(12) DIN 53436 – Plastics – UV exposure testing (Germany)

(1) Standardized Pretreatment: Provides a controlled environment for UV irradiation according to relevant helmet testing standards.

(2) Simulates Natural Aging: Replicates long-term sunlight exposure effects on helmet materials.

(3) Essential for Durability Testing: Prepares helmets for subsequent performance tests, including electrical insulation, mechanical strength, and anti-static evaluation.

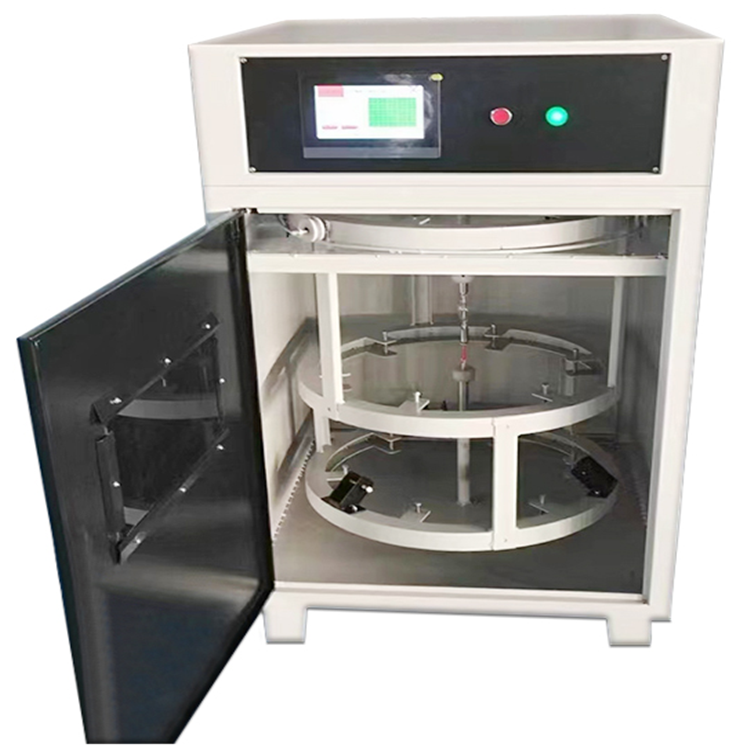

(4) Multiple Helmet Testing: Capable of pretreating up to 14 helmets simultaneously for high-throughput laboratories.

(5) Controllable Exposure Time: Timer range up to 999 hours for flexible preconditioning.

(6) High-Intensity UV Source: 450W high-pressure short pulse xenon lamp simulates the full spectrum of sunlight.

(7) Air-Cooled System: Maintains stable chamber temperature and prevents heat accumulation during prolonged UV exposure.

(8) Robust Laboratory Construction: Designed for durability and safe operation, minimizing operator exposure to UV radiation.

| Parameter | Specification |

|---|---|

| UV Radiation Source | 450W high-pressure short pulse xenon lamp |

| Cooling Method | Air-cooled |

| Timer Range | 0–999 hours |

| Maximum Helmets Pretreated | 14 units |

| Chamber Type | Enclosed UV irradiation chamber |

| Safety Feature | Operator protection against UV exposure |

| Construction | Laboratory-grade, corrosion-resistant materials |

(1) Helmet holding racks – 1 set

(2) Power cable – 1 set

(3) User manual – 1 copy

(1) Install helmets in the internal fixture or rack ensuring uniform exposure to UV radiation.

(2) Set the desired duration on the timer (0–999 hours) according to the test protocol.

(3) Start the UV irradiation process.

(4) The air-cooled system maintains a stable chamber temperature during the test.

(5) Upon completion, remove helmets for further testing, such as mechanical strength, electrical insulation, or anti-static performance assessments.

(1) Ensure the xenon lamp is clean and free of dust for consistent UV intensity.

(2) Replace the UV lamp periodically according to manufacturer guidelines to maintain radiation output.

(3) Keep the chamber interior clean and dry to prevent contamination of helmet samples.

(4) Verify timer and cooling system function regularly for accuracy.

(5) Store the instrument in a dust-free, well-ventilated area.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com