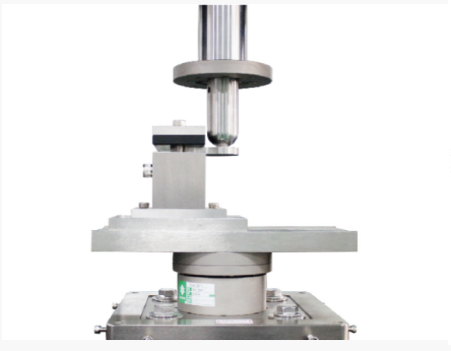

I. Main ApplicationsThe Tibial Tray Fatigue Testing Machine is primarily used to evaluate the f

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

YY/T 0810 (China): Specifies fatigue testing protocols for tibial trays in total knee arthroplasty, focusing on support and protection of plastic bearing surfaces.

ASTM F1800 (International): Defines methodologies for evaluating the fatigue strength of tibial components under cantilever loading conditions.

ISO 14879-1: Additional compliance for general fatigue testing of total knee joint prostheses.

Cantilever Loading Precision: Advanced actuator design ensures uniform stress distribution per ASTM F1800 requirements.

5 Million Cycle Endurance: Proven capability to complete YY/T 0810’s 5×10⁶-cycle fatigue test without calibration drift.

Dynamic Load Control: Closed-loop system maintains R=0.1 stress ratio during sinusoidal/random loading (0.1–10 Hz).

Real-Time Fracture Detection: AI-powered acoustic emission monitoring identifies micro-cracks at sub-millisecond intervals.

Intuitive Workflow: 21.5” capacitive touchscreen with gesture control and pre-loaded SOPs for 10+ implant geometries.

Modular Environmental Chambers: Quick-swap pods for simulated physiological (-20°C to +50°C) and corrosive environment testing.

Electromagnetic Actuator: 3.000 N peak force capacity with programmable load ratios (R=0.1–10).

Cantilever Loading System: Simulates physiological knee joint moments with ±20 mm axial displacement.

Dynamic Load Control: 0.1–10 Hz frequency range with programmable waveforms (sine, square, random, custom).

Thermal-Mechanical Chamber: ±0.3°C temperature stability with integrated humidity control (10–95% RH).

High-Speed Imaging Ready: Syncs with external cameras for full-field strain mapping (DIC optional upgrade).

Safety First: Triple-redundant emergency stop, overload clutches, and laser-based specimen breakage detection.

Tibial Tray Test Fixture Kit:

Self-centering collet system (28–40 mm tibial tray compatibility)

Laser-aligned loading anvils with diamond-like carbon (DLC) coating

Thermal-Mechanical Chamber:

15L capacity with rapid cooling/heating (15°C/min)

316L stainless steel interior with HEPA filtration

TestMaster Ultimate Software:

Automated S-N curve generation and fatigue limit calculation

21 CFR Part 11-compliant audit trail with blockchain timestamping

Remote monitoring via dedicated iOS/Android app

Operator Kit:

Calibrated torque wrench set (0.5–50 Nm)

Specimen alignment gauges (ASTM F1800 compliant)

Calibration Bundle:

NIST-traceable force calibration weights

Temperature/humidity verification probe

Safety Kit:

Laser safety curtains

Acoustic enclosure with 30 dB noise reduction

| Parameter | Specification |

|---|---|

| Max. Dynamic Force | ±3.000 N (6.000 N peak optional) |

| Frequency Range | 0.1–10 Hz (0.01 Hz increments) |

| Load Ratio (R) | 0.1–10 (adjustable) |

| Axial Displacement | ±20 mm (0.1 μm resolution) |

| Torque Capacity | ±20 Nm (0.01 Nm resolution) |

| Temperature Range | -20°C to +50°C (environmental chamber) |

| Humidity Control | 10–95% RH (non-condensing) |

| Data Sampling Rate | 100 kHz (synchronized across 16 channels) |

| Power Requirements | 220V/110V ±10%, 50/60Hz, 2.000W |

| Dimensions (W×D×H) | 1.500 × 1.000 × 2.000 mm |

| Weight | 750 kg (including environmental chamber) |

| Noise Level | <65 dB (A-weighted) |

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com