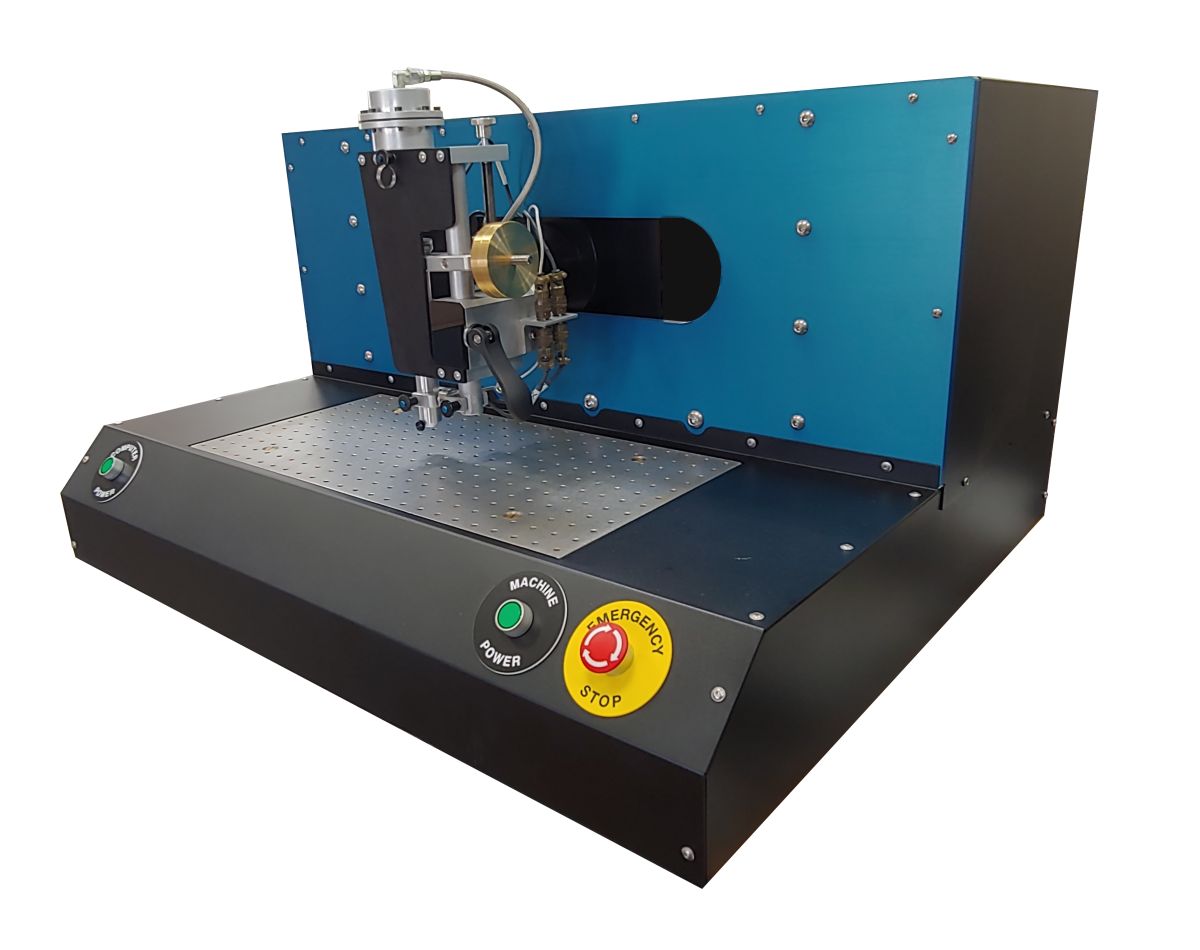

Macroscopic scratch/wear tester for polymers, coatings, films.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The Scratch 5.5 Machine is a research-grade tribology instrument for macroscopic scratch and wear testing of polymers, coatings, films, and bulk materials. It enables rigorous analysis of scratches, wear, and other surface properties for both research and industrial applications.

(1) Automotive Industry: Scratch and wear testing of interior panels, dashboards, bumpers, coatings, and painted surfaces.

(2) Aerospace Industry: Durability testing of aircraft interior panels, seating materials, and exterior composite coatings.

(3) Consumer Electronics: Scratch resistance testing for smartphone screens, laptop casings, tablet surfaces, and wear of plastic enclosures.

(4) Furniture & Home Products: Scratch and wear testing for laminated boards, varnished wood, coatings on furniture, and kitchen countertops.

(5) Food Packaging & Labeling: Resistance testing of plastic, paper, and coated packaging surfaces.

(6) Industrial Coatings & Pipelines: Downhole coatings, protective industrial surfaces, conveyor belts, and automated production line materials.

(7) Research & Quality Control Labs: Material development, surface coating R&D, and standardized wear/scratch testing for product certification.

(1) ASTM D7027-05 — Standard Test Method for Evaluation of Scratch Resistance of Plastics and Coatings

(2) ISO 19262-12 — Paints and Varnishes – Determination of Scratch Resistance

(3) ASTM D5178 — Standard Test Method for Cross-Cut Adhesion of Coatings

(4) TAMU/Avery-Dennison Mar Test Standard

(5) Ford 5 Fingers Method

(6) Erichsen Cross Hatch Test

(7) Pencil Hardness Test (Dead Load)

(8) Volkswagen PV3952 Standard

(9) GM 14688-A-10N

(10) ISO 15184 — Plastics – Determination of Scratch Resistance Using a Scratcher

(11) ISO 14577 — Metallic Materials – Instrumented Indentation Test for Hardness and Mechanical Properties

(1) Multiple test modes: Rise, fall, dead load scratches, reciprocating wear, and indentation testing.

(2) High precision loading: Maximum normal and tangential load up to 400 N, with micron-level depth resolution.

(3) High-speed data acquisition: Up to 2000 tangential data points per second.

(4) Programmable load curves: Progressive or constant load, speed adjustable from 1–400 mm/s.

(5) Large stroke & high load capability: Maximum depth 50 mm, optional puncture testing.

(6) Multi-industry applications: Automotive, aerospace, electronics, furniture, food packaging, and industrial production lines.

| Parameter | Specification |

|---|---|

| Axes | 4-axis instrument |

| Tangential Load | Up to 400 N |

| Normal Load Accuracy | 0.05% (600 N), 0.25% (100–200 N) |

| Stroke | 50 mm, Accuracy ±5 μm |

| Data Acquisition | Up to 2000 points per second |

| Loading Speed | 1–400 mm/s, programmable |

| Load Range | 0.5–400 N, progressive or constant |

| Optional Functions | Puncture testing, high-speed high-load test, programmable progressive load curve |

(1) Standard test sample holders and fixtures

(2) Touch-screen control software

(3) Data recording and printing system

(4) Optional puncture testing module

(5) Power supply and connection cables

(1) Install the sample according to the test requirement and select the test mode (rise, fall, or dead load).

(2) Set the load range, loading speed, and load curve type (progressive or constant).

(3) Start the test; the machine performs scratch or wear testing automatically.

(4) Collect load, depth, and tangential data in real time.

(5) Export data and generate the test report after completion.

(1) Keep the instrument clean; avoid dust and liquid contamination on sensors and loading mechanisms.

(2) Calibrate load and depth sensors regularly.

(3) Lubricate mechanical moving parts as necessary.

(4) Update software and control systems to ensure stable operation.

(5) Do not disassemble core components unless by qualified personnel, to avoid accuracy issues.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com