Robotic mannequin tests CB protective gear during military movements in harsh environments.

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

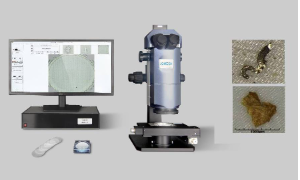

The Cleanliness Tester is an advanced instrument for detecting and analyzing particle contamination on automotive parts, new energy power battery components, and other precision-engineered products. The system automatically counts and classifies impurity particles on filter membranes by type, size, and quantity, providing standardized reports aligned with automotive and medical industry standards.

(1) Automotive Powertrain Components: Engine parts, fuel injectors, transmission components, and precision metal parts.

(2) New Energy Battery Parts: Lithium-ion battery electrodes, separators, and casings for electric vehicles.

(3) Medical Devices: Sterile surgical instruments, medical implants, and single-use disposable devices.

(4) Aerospace Components: Turbine parts, hydraulic systems, and avionics housings.

(5) Defense & Military CB Equipment: Protective gear and sensitive equipment requiring ultra-clean surfaces.

(6) Industrial Manufacturing: Precision machined parts, semiconductor components, and hydraulic systems requiring particle-free assembly.

(1) ISO 16232 — Road Vehicles — Cleanliness of Components of Fluid Circuits

(2) ISO 4406 — Hydraulic Fluid Power — Contamination Code for Fluids

(3) VDA 19 — Germany Automotive Industry Standard for Component Cleanliness

(4) ISO 10993-12 — Medical Devices — Biological Evaluation — Sample Preparation & Reference Materials

(5) ASTM F2459 — Standard Test Method for Particle Contamination in Medical Devices

(6) ASTM E1019 — Standard Test Method for Elemental Analysis by ICP

(7) ASTM E1447 — Standard Guide for Particle Counting

(8) ASTM E1409 — Standard Test Method for Determining Particle Size in Contaminated Fluids

(9) OEM Standards — Volkswagen, BMW, Ford, Mercedes-Benz, GM powertrain component cleanliness specifications

(1) Automatic identification and classification of metal particles, non-metal particles, and fibers.

(2) Particle counting and length grading according to ISO 16232.

(3) Measurement of individual particle dimensions (length, width).

(4) Hardware support with polarized light to accurately distinguish metal vs. non-metal particles.

(5) Multi-language software interface (Chinese, English, German).

(6) Automatic image stitching and storage of scanned filter membranes; re-analysis and customizable report generation.

(7) Free-travel high-precision scanning stage with manual or automatic control.

(8) Equipped with calibrated microscope standard block and camera scale calibration block.

(9) Special bracket supports 25 mm, 47 mm, 50 mm filter membranes without repositioning.

(10) Scanning results for nylon mesh braided film equivalent to surface filter films; grid does not affect results.

| Parameter | Specification |

|---|---|

| Optical System | Excitation Wavelength: 365 nm; Detection Wavelength: 460 nm |

| Measurement Spot Diameter | 1 mm |

| Optimal Measuring Distance | 4.7 mm |

| Measurement Range | Cleanliness: 0–100% (Resolution 0.1%) |

| Fluorescence Intensity | Accuracy: 0.1 RFU, Deviation ≤ 0.5% |

| Oil Film Thickness | User-defined; supports rust-proof oil and adhesive monitoring |

| Power Supply | Rechargeable lithium battery, USB/AC adapter |

| Hardware Design | Handheld, integrated sensor head and display for complex geometric surfaces |

(1) Filter membrane holders (supports 25 mm, 47 mm, 50 mm membranes)

(2) Calibrated microscope standard block with certificate

(3) Camera scale calibration block

(4) Software for automatic scanning, image processing, and report generation

(5) User manual (Chinese, English, German)

(1) Install the filter membrane on the special bracket without repositioning.

(2) Select the measurement type (metal, non-metal, fiber) in the software interface.

(3) Set scanning parameters and initiate automatic scanning or manual operation.

(4) The system automatically identifies, counts, and classifies particles, and calculates dimensions.

(5) Review and export scanned images and cleanliness data reports.

(6) Optionally, manually adjust and re-analyze particles if required.

(1) Clean optical components and sensor heads regularly to prevent contamination.

(2) Calibrate using the microscope standard block every two years.

(3) Avoid exposing the instrument to extreme humidity or temperatures.

(4) Keep software updated to maintain scanning accuracy and reporting functionality.

(5) Store filter holders and accessories in a clean, dust-free environment.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com