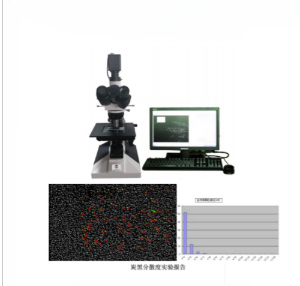

Scope of application:DW1431 plastic carbon black dispersion measurement system is based on a profess

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The carbon black content tester is a precision instrument specifically designed for measuring the carbon black content in plastics such as polyethylene, polypropylene, and polybutylene, as well as in rubber.

DW1431 plastic carbon black dispersion measurement system is based on a professional image acquisition system and corresponding software, through the measurement of the scale, form, and dispersion of carbon black particles, effectively evaluate the dispersion state and dispersion uniformity of carbon black particles in polyolefin geosynthetic materials, pipes, pipe fittings and mixed ingredients, pigment or carbon black materials, that is, carbon black dispersion. Carbon black is a good ultraviolet stabilizer, the best light absorber and light screen agent, which can effectively improve the anti-ultraviolet and anti-aging properties of plastic products. The content of carbon black and the dispersion of carbon black in plastic media will have a decisive effect on the UV protection, mechanical properties and life of plastic products. Through the measurement of the scale, shape and dispersion of carbon black particles, the internal relationship between these parameters and macro performance indicators such as mechanical properties, antistatic properties and hygroscopic properties can be established, which will ensure the quality of plastic materials and the production process.

New product research and development has a positive impact, while promoting the rapid improvement of the technical level of enterprises and industries.

GB/T 18251-2019:Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin pipes, fittings and compounds

ISO/DIS 18553-1999 ASTM D5596-2003:Corrosion of metals and alloys - Measurement of crevice corrosion resistance of stainless steels by the critical crevice solution method

CJ/T 234- Appendix D-2006:Appendix D (Normative) of CJ/T 234-2006 - [Specific Test Method or Requirement]

GB/T 17643- Appendix E-2011: Appendix E (Normative) of GB/T 17643-2011 - [Specific Test Method or Requirement]

The optimized design of the heating furnace features an aesthetically pleasing structure, stable performance, and reliable quality;

The openable furnace door structure facilitates sample loading and precise positioning of the sample;

The intelligent temperature control system provides automatic heating and high temperature control accuracy;

Up to 30 temperature program segments can be set, allowing for different heating temperatures, heating rates, and holding times;

The furnace chamber exhibits excellent temperature uniformity and stable temperature control;

Cooling air ducts are installed at both ends of the furnace body, facilitating heat dissipation and sample cooling, improving safety and convenience;

A float-type gas flow meter is used for easy and rapid switching between two gas lines, allowing for precise gas flow adjustment, short stabilization time, and long-lasting durability.

| Description | Details |

|---|---|

| Test methods | Microscopy |

| Magnification | >50x |

| Image sensor | CCD camera system |

| Imaging resolution | 976x582 pixels |

| Detection range | 5 - 150um |

| Rating method | Automatic or manual |

| Sample preparation method | Tablet or slice method |

| Power supply | AC 220V 50Hz |

| Overall dimensions | 450x210x450mm |

| Weight | 9KG |

Heating furnace and main unit

Instruction manual

Power cable

Sample boat (or combustion boat)

Quartz tube

Gas piping system (may include gas tubing, pressure reducing valve connectors, gas connectors, etc.)

Sample hook

Sample boat holder

Exhaust tube

Crucible tongs

Tube plug (may be included with some models)

Temperature sensor (or temperature control probe)

Flow meter and regulating valve (for controlling gas flow)

Sample preparation: Weigh 1g of the sample to be tested and place it in the combustion boat according to the test procedure.

Instrument preheating: Turn on the instrument, purge with nitrogen for a few minutes, and set the heating program.

Sample placement: Place the prepared sample into the quartz tube.

Start testing: Press the test button. Remove the sample after the test is completed.

Data processing: Calculate the test results according to the formula.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com