Mainly used for building materials and their products when the static smoke generated by the determi

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

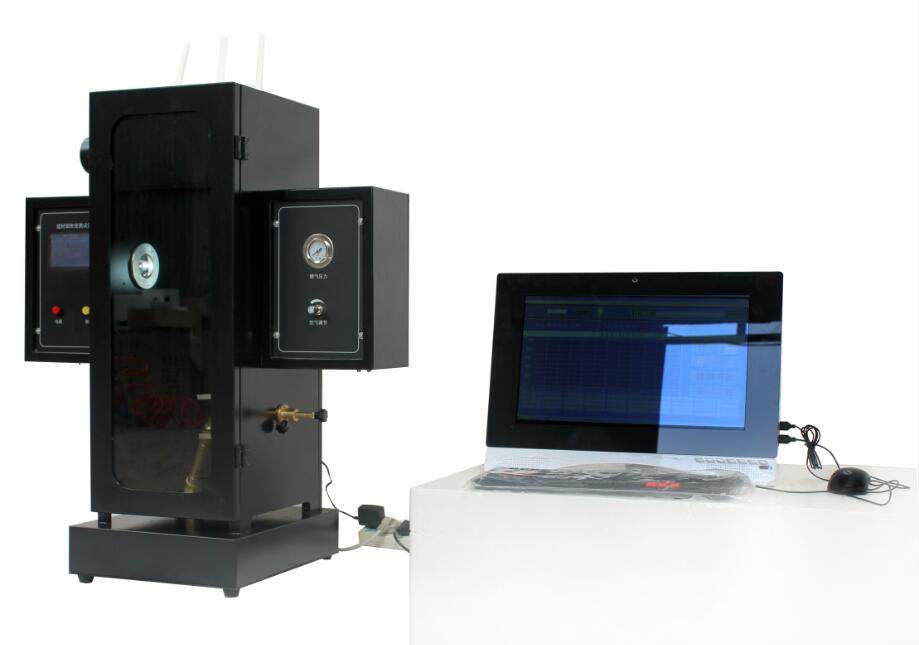

The Smoke Density Tester, developed by Rohm and Haas in the 1970s based on ASTM D2843. measures smoke optical density during combustion using direct flame impingement (Billung's law). It calculates the Smoke Density Rating (SDR) and is now widely applied internationally for testing PVC conduits and automotive interior materials.

Smoke density meters are widely used in various industries, including but not limited to the following:

Building Materials: Evaluating the combustion performance of building materials to provide a reference for building design and material selection.

Plastics and Textiles: Testing the smoke density produced by these materials during combustion to ensure they meet safety standards.

Fire Safety: Testing the smoke release characteristics of materials by simulating fire environments to provide data support for the fire safety design of buildings.

Environmental Protection: Evaluating the smoke emissions of materials during combustion to ensure they comply with environmental regulations.

ASTM E662: Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials

ASTM F814: Test Method for Specific Optical Density of Smoke Generated by Solid Materials for Aerospace Applications

NFPA 258: Research Test Methods for Determining Smoke Generation of Solid Materials

Boeing BSS 7238: Test Method for Smoke Generation by Materials on Combustion

FAR Part 25 Appendix F Part V: Test Method To Determine the Smoke Emission Characteristics of Cabin Materials

Aircraft Materials Fire Test Handbook Chapter 6: Chapter 6 of Aircraft Materials Fire Test Handbook

Airbus AITM 2.0007A: Determination of the Specific Optical Smoke Density of Component Parts or Sub-Assemblies of Aircraft Interior

Airbus AITM 2.0007B: Determination of Specific Optical Smoke Density for Wires and Cables in Aircraft

IMO MSC.61 (67) Annex 1 Parts 1&2: Fire Test Procedures for Ship Materials

ISO 5659-2: Plastics — Smoke generation — Part 2: Determination of optical density by a single-chamber test

IMO FTCP Part 2: Smoke And Toxicity Test

BS 6401: BS 6401 - [Specific Title Related to Smoke Testing](

ABD0031: Airbus Fireworthiness Requirements: Generation of Smoke and Toxic Gases

Durable Teflon-Coated Chamber:

The test chamber is lined with Teflon, providing strong resistance to the corrosive effects of combustion-generated smoke, which significantly extends the lifespan of the equipment.

Clear Visibility Markers:

The bottom of the chamber features an "EXIT" sign in white letters on a red background. This allows test personnel to easily observe the clarity or blurriness of the sample through the transparent observation window.

Precision Light Sensing:

The tester uses an incandescent light source paired with a silicon photodiode as the light sensor, calibrated with cosine corection. Equipped with color filters, it effectively blocks UV and IR light that is not visible to the human eye, ensuring accurate color matching.

High-Pressure Flame Impact:

The main burner applies a flame to the test sample at a pressure of 276 KPA. An auxiliary burner is also included to subject any dripping material to additional flame impact, operating at a gas pressure of 138 KPA to ensure thorough combustion of molten droplets.

Advanced Data Display:

The standard test software provides light transmittance values every 15 seconds, generating a transmittance test curve. After the test, it calculates and displays the SDR (Smoke Density Rating) value, which represents the integral value of the smoke produced.

Comprehensive Test Reporting:

The software can compile and synthesize test reports from three sample groups, creating an SDR smoke density development curve. It also allows simultaneous comparison of SDR values from three tests, automatically determining compliance with testing standards.

User-Friendly Data Management:

Test data can be easily exported to a computer and connected to a printer for convenient report generation and printing, enhancing user accessibility and efficiency.

Mainly used for building materials and their products when the static smoke generated by the determination of smoke, is the test of textile materials, solid material burning smoke production of special equipment.

| Burning lamp | for the students light, length 260mm, nozzle diameter 0.13mm, 45 ° angle with the smoke box; |

| Photoelectric system | light source for the lamp, power 15W, operating voltage 6V; |

| Exhaust system | the machine is equipped with a strong fan, after the test, the exhaust can be discharged outdoors; |

| Smoke density measurement range | 0 ~ 100%; |

| Smoke density measurement accuracy | ± 3%; |

| Receiver | for the silicon photovoltaic cells, light transmission rate of 0% for the passage of light, light transmission rate of 100% light without cover completely through; |

| Main burner working pressure | 276KPa (adjustable); |

The main accessories of a smoke density tester include the following categories, and their functions are briefly described below:

Smoke Box: As the core component of the tester, it is used to contain the sample and collect the smoke generated during combustion.

Combustion System: Includes main/auxiliary dual burners, nozzles, igniters, etc., used to provide a stable flame to ignite the sample.

Photoelectric Detection System: Composed of a light source (such as a bulb or laser), photodetectors (such as silicon photocells or photomultiplier tubes), filters, etc., used to measure the degree of light attenuation by smoke, thereby calculating smoke density.

Exhaust System: Includes exhaust fans, exhaust ducts, etc., used to exhaust exhaust gases outdoors after the test, maintaining a clean testing environment.

Sample Clamp: Used to fix the sample, ensuring its stability during combustion.

Standard Filter: Used to calibrate the instrument, ensuring the accuracy of measurement results.

Control Software and Data Acquisition System: Used to control the testing process, collect data, and generate test reports.

Other auxiliary accessories: such as power cord, rubber tubing, medium pressure valve, USB flash drive (containing device software program), instruction manual, certificate of conformity, etc.

The operation method of a smoke density tester includes the following steps:

Installation Check: Ensure the smoke density tester's battery is charged and the sensor is clean. Check if the environmental conditions of the test area meet the requirements.

Parameter Setting: Select the test mode, set the time interval, and determine the test range as needed.

Aiming at the Smoke Source: Aim the tester's sensor at the smoke source or emission source in the test environment, ensuring the sensor can accurately receive the scattered light from smoke particles.

Maintaining a Stable Position: Ensure the accuracy of the test results by avoiding vibration and human interference.

Data Recording: After the test, review the results and record and save the data as needed.

Regular Calibration: Regularly calibrate the smoke density tester to ensure the accuracy of the test data.

Sensor Cleaning: Clean the sensor regularly to prevent dust, oil, or other impurities from affecting the test results.

YouTube video introduction : https://www.youtube.com/watch?v=Ps0-Q0SiuMQ&t=21s

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com