The Fully Automatic Spinneret Mirror Inspection Instrument (Detector) is designed for automatic insp

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

The Fully Automatic Spinneret Mirror Inspection Instrument (Detector) is designed for automatic inspection of chemical fiber filament spinnerets, staple fiber spinnerets, and industrial yarn spinnerets of various shapes and specifications, including round, square, and rectangular dies. The instrument can also inspect spinning plates, spinneret mouthplates, and other specialized dies for hole shape, size, and blockage.

By analyzing the shape, size, and arrangement of spinneret holes, this instrument can detect any hole within the effective vertical and horizontal ranges, ensuring comprehensive and accurate inspection.

Produced according to GB/T19001-2016 / ISO9001 quality management system.

Mechanical and electrical design conforms to GB 5226.1-2008 standards.

Three-Axis Motion Control: Uses an automatic X-Y-Z three-axis platform (orthogonal robot) with imported AC servo positioning. Each axis features a precision ball screw drive, ensuring low noise, high precision, and repeat positioning accuracy up to ±0.01mm.

High-Resolution Lens: Equipped with a high-pixel lens with low distortion. No lens replacement is required when switching magnifications.

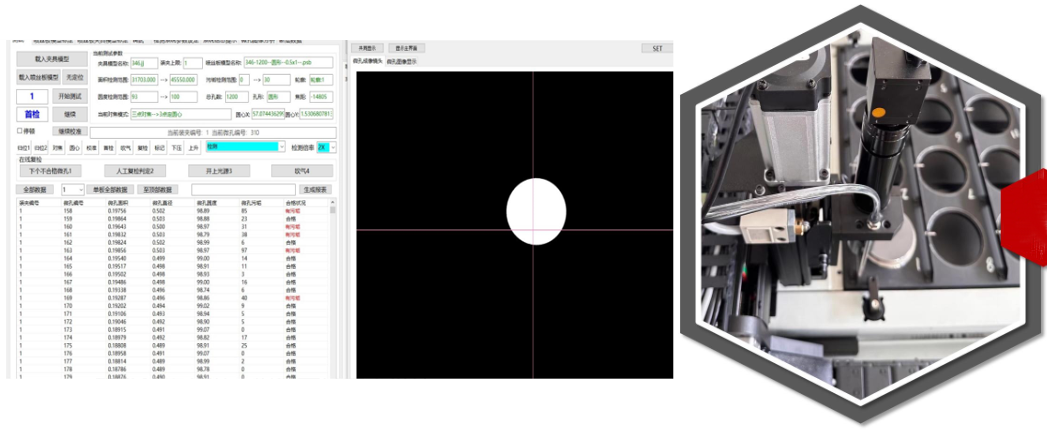

Industrial Camera: High-speed, high-resolution black-and-white industrial camera ensures distortion-free image capture for accurate measurement.

High-Strength Loading Fixture: Metal fixtures and table provide excellent load-bearing performance, easy replacement, and ensure flatness via precision grinding.

Display Interface: Built-in display allows real-time observation of the inspection process.

Advanced Image Processing: Detects hole diameter, area, roundness, fouling rate, and other parameters automatically. Position of unqualified holes is recorded.

Custom Spinneret Templates: Users can input spinneret parameters for calibration.

Automatic Focusing: Lenses automatically adjust focus, improving inspection efficiency.

Data Management: Test results are stored in a database for easy recording and analysis.

Optimized Detection Path: Detection rate per hole: 0.2–1s, depending on spinneret specifications.

Flexible Operation: Different spinnerets can be tested by loading corresponding template files.

Industrial Control Computer: Equipped with X-Y-Z control, I/O card, adjustable light source controller, keyboard, and mouse for fast data transmission.

LED Illumination: Long-life LED light source ensures uniform lighting through spinneret holes for high-quality image capture.

All-in-One Design: High-strength metal construction with convenient spinneret fixture replacement.

Hole-by-Hole Scanning: Fully automatic scanning of all spinneret holes using computer-controlled image processing.

Automatic Defect Handling: Unqualified holes are recorded, can be cleaned with compressed air, or marked using a coaxial light source.

Full Automation Definition: The microscope automatically inspects and records position coordinates of each hole, including abnormal holes. Air blow cleaning and visual marking ensure precise defect management.

Hole diameter

Hole area

Roundness (out-of-roundness rate)

Fouling rate

Qualified/unqualified hole identification (green: qualified, red: unqualified)

Special-shaped hole size

The software provides dual interfaces:

Data Interface: Displays all detection data numerically.

Graphical Interface: Shows real-time inspection images for intuitive analysis.

| Parameter | Specification |

|---|---|

| Detection Area | 500 × 500 mm (customizable) |

| Test Table Size | 850 × 700 × 1390 mm (customizable) |

| Detection Items | Hole diameter, area, roundness, fouling rate, special-shaped holes |

| Detection Speed | 0.2–1 s/hole (depends on hole spacing) |

| Detection Accuracy | ±0.01 mm |

| Detectable Hole Range | 0.1–5 mm |

| Maximum Spinnerets per Run | Depends on spinneret size (e.g., φ88 mm, max 30 pieces) |

| Motion Control | 3-axis robot with servo motors and ball screws |

| Camera | 1.4 MP high-speed black-and-white camera |

| Lens | Imported continuous zoom lens, low distortion |

| Light Source | Upper and lower LED, fully covers spinneret |

| Software | Simplified Chinese; customizable to English, Traditional Chinese, etc. |

Micro-hole Analysis

Measures hole diameter, area, roundness, fouling rate, qualified/unqualified status, and special-shaped hole dimensions.

Users can define custom criteria to judge if a hole is qualified, whether its area is too large or too small, and if the detected micro-hole status falls within the preset range.

Visual indication: Unqualified holes are highlighted in different colors in the software for intuitive assessment.

Dual Interface Display

Data Interface: Displays complete micro-hole detection data numerically.

Graphical Interface: Provides real-time visualization of inspected holes for immediate feedback and analysis.

Aperture Measurement

Measures hole size to serve as a reference for spinneret inspection.

Detected data can be directly saved in the computer for record-keeping and further analysis.

Layered (Tomographic) Scanning

Automatically scans holes to detect internal fouling.

Standard quick inspection only captures the surface due to depth-of-field limitations.

Optimized software algorithm enables layered scanning, dividing the spinneret hole length into multiple sections and reporting fouling values for each segment.

1.Place the spinneret plate on the fixture.

2.Set inspection parameters in the software.

3.Automatic focusing and positioning of the lens.

4.Automatic hole-by-hole scanning, generating detection data and images simultaneously.

5.Automatic qualification assessment of each hole.

6.Automatic cleaning (blow air) or marking of unqualified holes; manual intervention is also possible.

7.Completion of the inspection and data storage.

All test data is stored in the computer for future reference.

Visualizes the spinneret micro-hole distribution for each plate.

Enables long-term statistical analysis to enhance quality control and management of spinneret manufacturing.

High Accuracy & Reliability: Eliminates human error, ensures quality, and prevents defective products.

Labor & Cost Savings: Fully automatic operation 24/7 reduces manpower and recovers investment quickly.

Incoming Spinneret Inspection: Measures actual hole sizes before installation, avoiding defects during production.

Data Management: Stores micro-hole data to support production optimization and removal of unqualified spinnerets.

Process Improvement: Detects concentrated abnormalities to identify production issues such as temperature deviations or clogging.

Data saved after each inspection; previous inspection records remain intact.

Spinnerets can be cleaned using compressed air with optional seal or light source positioning marks.

Consumable parts are easy to replace.

Complete user manual provided, including precautions, maintenance, and troubleshooting.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com