Product DescriptionMattress durability testing machine. This test is mainly used to evaluate the res

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

Product Description

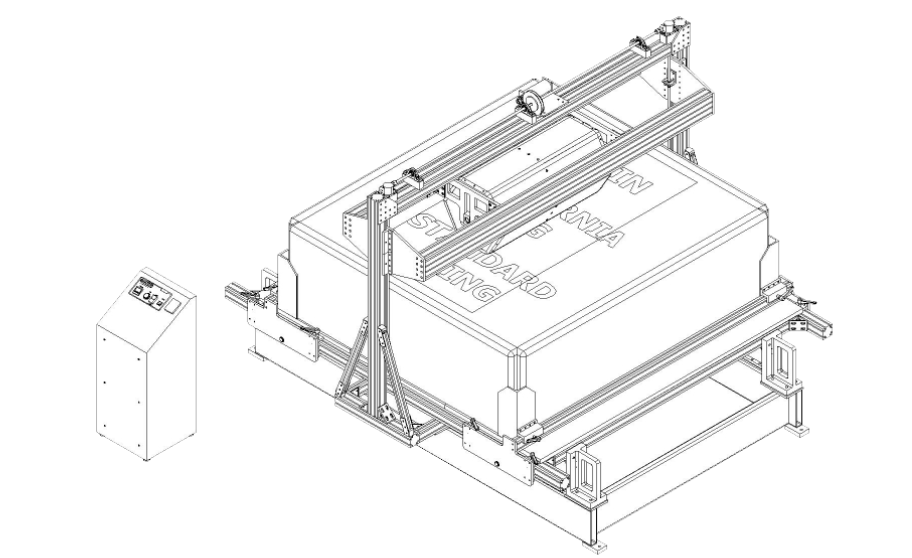

Mattress durability testing machine. This test is mainly used to evaluate the resistance to fatigue pressure and surface wear of the springs, foam and other elastomers in mattresses, seats, sofas, etc. after a certain number of reciprocating compressions.

Product Specifications

Standard Accessories

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com