I. Definition and Working Principle

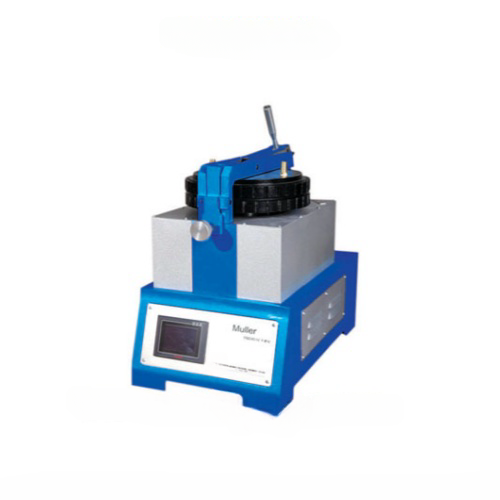

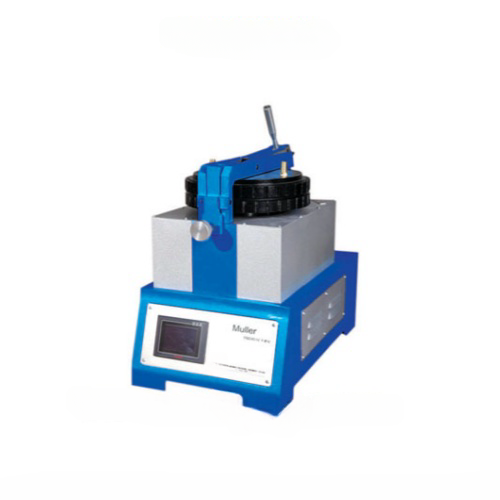

- Digital Grinding Machine is a laboratory equipment that

uses mechanical force to crush, mix, and grind samples. Its core working

principle utilizes rotational or vibrational forces to enable sample

refinement through collisions and friction between grinding media (e.g.,

agate beads, glass beads, stainless steel beads).

- Equipped with digital display and control system for precise

parameter settings (e.g., grinding time, speed) and real-time monitoring.

II. Key Features

- Precision Control: Digital interface enables exact

settings for grinding duration and rotational speed.

- Multi-functional Adaptability:

- Compatible with various grinding media

(agate/beads/glass/stainless steel)

- Applications span agriculture, food science, biology,

environmental science, and mineral processing

- Intelligent Automation:

- Overload/overheat protection

- Timed operation

- Automatic shutdown

- Maintenance-Friendly Design: Easy disassembly and cleaning

mechanisms

III. Application Fields

- Agriculture: Grain processing, oilseed analysis, soil

testing, tobacco preparation

- Food Industry: Feed homogenization, cheese processing,

fruit puree preparation

- Biology: Bone tissue grinding, hair sample preparation,

cell disruption

- Environmental Science: Fertilizer analysis, e-waste

recycling, sludge treatment

- Mineral Metallurgy: Alloy processing, coal crushing, ore

refinement

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.