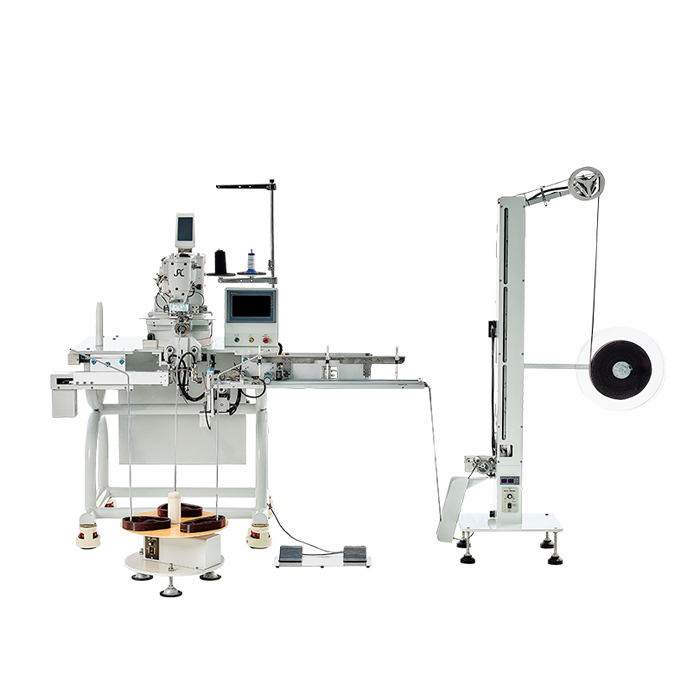

Scope of application: Men's underwear, sports pants, casual pants, sweaters, bras, beach pants, etc.

Email: info@standard-groups.com

Men's underwear, sports pants, casual pants, sweaters, bras, beach pants, etc.

1、Equipped with high-end counter, which can realize complete counting function

2、Double the bobbin to reduce the frequency of shuttle change

3、No bottom line, automatic stop when disconnected, to prevent material waste

4、Equipped with middle presser foot to provide more stable sewing quality

1、Equipped with high-end counter, which can realize complete counting function

2、Double the bobbin to reduce the frequency of shuttle change

3、No bottom line, automatic stop when disconnected, to prevent material waste

4、Equipped with middle presser foot to provide more stable sewing quality

Power:0.8KW

Sewing machine revolution:2800rpm(max)

Possible rubber width:5mm-60mm

Splicing length:120mm-999mm

Smallest possible circumference:150mm

Maximum overlapping width:25mm

Measurement reeling out system:Pulse motor system

Pattern memory :Storage card(SD)

Maximum numbers of patterns:Maximum 2G

Materials cutting method:Cold Kinfe cut

Applicable fabrics :Elastic ribbon/woven/Fabric/Lace

Sewing production:800-900个/H 800-900 piece/H

Splicing range:Splicing range of tacking machine is within 6 cm/Pattern machine within 8 cm

Splicing method:Two ways of flat connection and overlap connection

Disclaimer: The above content is for reference and communication only among industry insiders, and does not guarantee its accuracy or completeness. According to relevant laws and regulations and the regulations of this website, units or individuals who purchase related items should obtain valid qualifications and qualification conditions.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com