Standards:ASTM316, GB/T32361-2015Applications:Scope of use:Suitable for samples of various materials

Email: info@standard-groups.com

ASTM316, GB/T32361-2015

Scope of use:

Suitable for samples of various materials such as polymers, ceramics, glass, metal, paper, cloth and composite materials.

Suitable for polymer membrane, filter paper, sintered metal, foamed metal, wire mesh, sintered felt, porous ceramics, non-woven fabric, fused sand glass and other types of membranes and filter materials.

Suitable for samples of various shapes such as tube type, multi-channel type, sheet type, hollow fiber, capsule type, and folded type.

For special samples, provide reliable testing process and various accessories required, and share our experience in testing various special samples with customers.

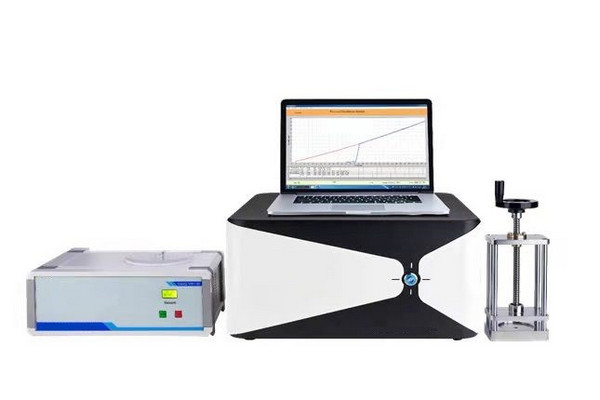

Fully automatic membrane pore size analyzer, including micro-filtration membrane pore size analyzer based on capillary flow method (bubble point method), ultra-filtration membrane pore size analyzer based on liquid-liquid replacement method, and multifunctional membrane performance tester, suitable for analysis Pore size distribution of various micro-filtration materials, the testing process is fully automatic and intelligent, and can accurately measure bubble point pressure, maximum pore size, average pore size, most probable pore size, gas flux, gas permeability, pore size distribution, etc

➤Bubble point pressure

➤Maximum diameter

➤Average diameter

➤Pore size distribution

➤Gas permeability

➤Model Name: GDA

➤Power supply: 220V,AC50Hz,120W

➤Communication method: RS485

➤Dimension: 480(L)×410(W)×240(H)mm

➤Working medium: cylinder nitrogen, compressed air

➤Testing pressure: 0-6bar

➤Testing flow: 0~50L/min

➤Aperture test range: 0.08~500μm

➤Working environment Ambient temperature: 5-40℃, Relative humidity: 10-80%

➤Sample size Diameter: 1-50mm

➤Special sample requirements: can be customized

➤Accessories: computer, vacuum infiltrator, professional wetting agent, test sample cell

1、Usage:

Use gas bubble pressure method to test the bubble point pressure, maximumpore size, averagepore size, most probable pore size, pore size distribution map, gas flux and gas permeability of variousmicro-filtration membrane materials; Able to measure orifice size and distribution

2、Technical Specifications:

2.1 Working medium: compressed air, cylinder gas;

2.2 Flow range:0~50L/min;

2.3 Pressure range:0~600kPa;

2.4 Vacuum infiltration device: it can infiltrate sheet film with diameter of 5~70mm, tubular filmwithdiameter of 5~70mm and length of 5~100mm; it has the function of displaying vacuumdegreeandinfiltration time;

2.5 Special specification sample cell can be customized, suitable for irregular samples;

2.6 Fully automatic computer program testing, one-click export of test results;

2.7 Voltage (V): 220;

2.8 Environment temperature (℃) :4 ~ 40;

2.9 Air supply interface (mm): 6;

3、Aperture test range:0.08~ 500um

4、System Configuration:

Aperture analyzer host 1 set

data processing software 1 set

test components(sample cell) 1 set

vacuum infiltrator 1 set

G-10 lubricant 4 bottles

End user needs to prepare following accessories: 1 computer, 1 nitrogen cylinder, 1 nitrogenpressurereducing valve

Disclaimer: The above content is for reference and communication only among industry insiders, and does not guarantee its accuracy or completeness. According to relevant laws and regulations and the regulations of this website, units or individuals who purchase related items should obtain valid qualifications and qualification conditions.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com